Squeezer (semi-melting type)Plastic squeezer Machine - Kitech

Raw Materials

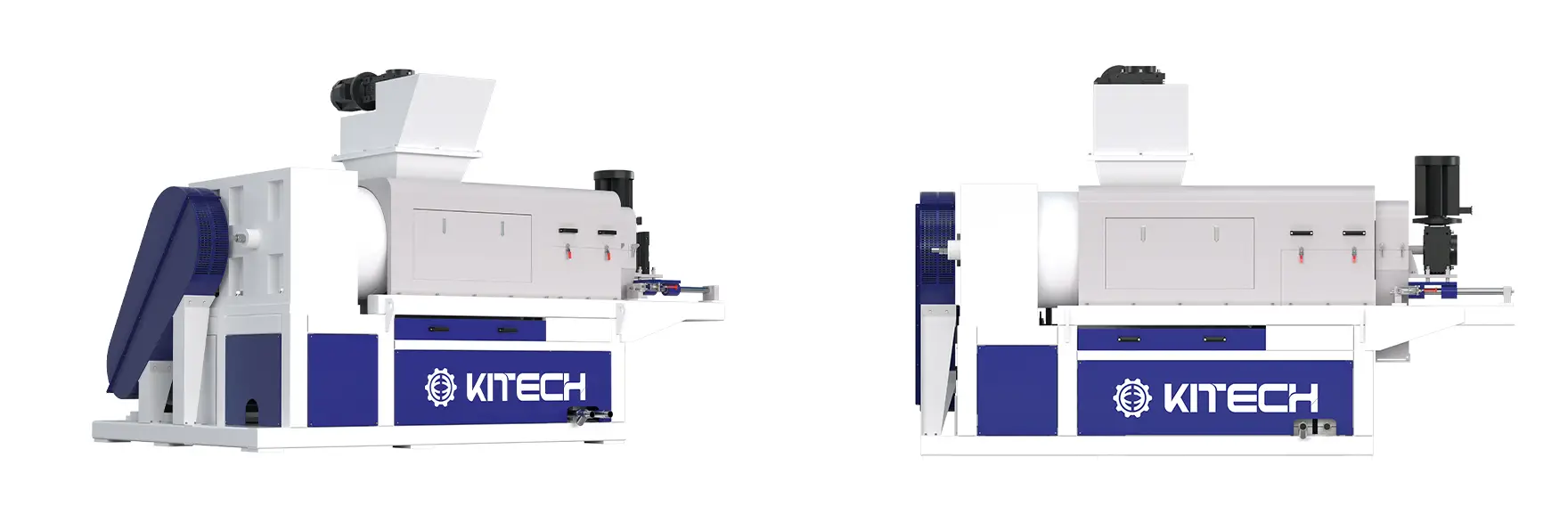

Squeezer (semi-melting type)

Kitech JGM series Plasticizing type squeezing dryer is used for the dehydration of LDPE stretch film/agricultural film/PP woven bag and some other thin soft waste plastic , it's equipped with the special high quality screw. Which can dewatering and drying the washed material by the strong press and squeezing power. Materials enter the barrel and screw through the hopper, and the screw squeezes the material with high strength. After pressing, the material is pushed into the die surface cutter and finally cut into semi-plasticized particles, after being squeezed, semi-plasticized particles with much lower moisture and higher density can be faster, easier and more stable fed into pelletizing machine. Which can improve the efficiency of pelletizing machine.

Specially designed high torque gear box and self-developed thrust bearing seat, bring strong screw thrust, the drying effect is better.

JGM series Plasticizing type squeezing dryer with the screw squeezing and electrical heating can effectively control the final humidity of the material at 3-5%, the capacity range is 200-1000kg /h. it can be used alone or connected with the washing production line, the operation is simple.

Product Parameters

| Model | JGM300 | JGM320 | JGM350 | JGM380 |

| Motor Power | 110KW | 132KW | 185KW | 200KW |

| Cutting Power | 4KW | 4KW | 5.5KW | 5.5KW |

| Screw&barrel Material | 38CrMoAl | 38CrMoAl | 38CrMoAl | 38CrMoAl |

| Screw diameter | 320mm | 320mm | 350mm | 380mm |

| Capacity/Hour | 200-300kg/h | 300-500kg/h | 500-800kg/h | 700-1000kg/h |

| Length in mm [A] | 2516 | 3070 | 3624 | 4178 |

| Height in mm [B] | 2205 | 2257 | 2309 | 2361 |

| Width in mm [C] | 2240 | 2320 | 2400 | 2480 |

product Advantage

- Reduce moisture level to 3-5%, increase pelletizing efficiency, improve pellets quality.

- More stable operation and long equipment life

- Low noise and less space required

- Cut frequency control, uniform and stable.

- PLC automatic control, simple operation and more convenient maintenance.

- Semi-plasticized particles can be used for pelletizing or sold directly.

- One machine realizes the functions of three machines (centrifugal dryer, hot air dryer, Agglomerator), which is more efficiency and economical and energy saving.

video