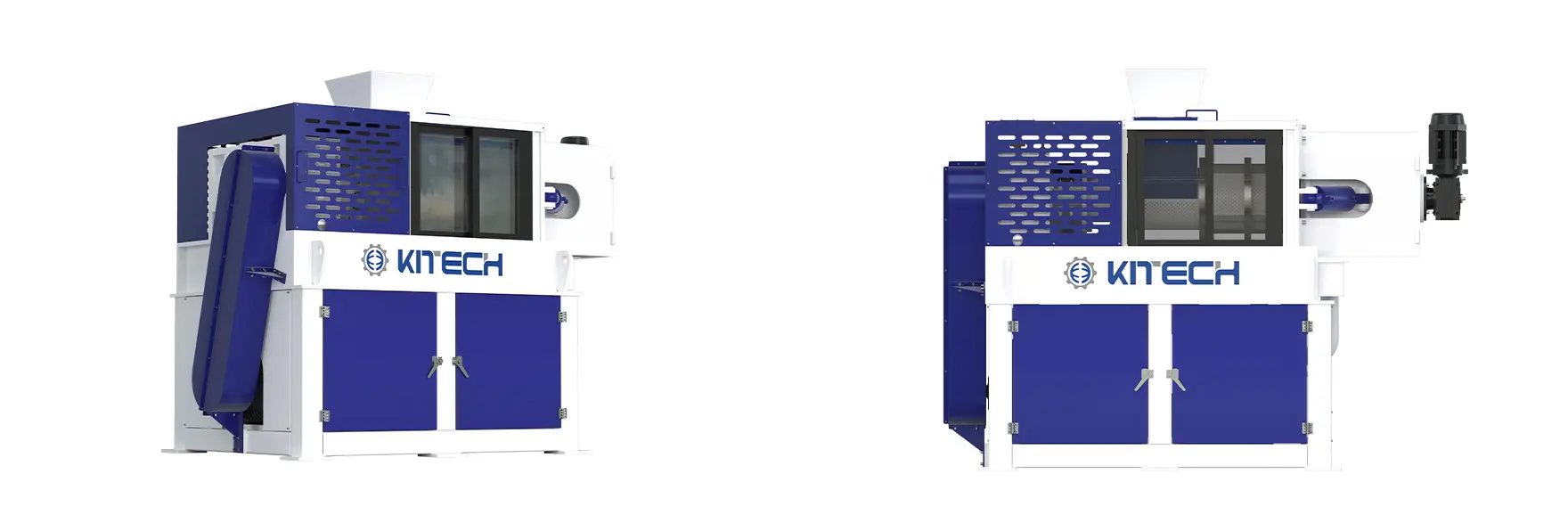

Squeezer (Non-melting type)Plastic squeezer Machine - Kitech

Raw Materials

Working principle

KHS series hydraulic squeezer is applied for drying LDPE industry film/bag and PP woven bags, normally it’s installed at the end of washing lines, inside the squeezer, there is a special designed screw which compress the material continually.

During pressing, there is strong friction between the material and the machine, and generates friction heating, which helpful for drying.

At the outlet of the machine, there is a hydraulic valve. At the beginning it is closed, and the more material compressed, the higher pressure the valve bear. when hydraulic pressure reached the set point. Then the valve opens for discharging the material.

Product Parameters

| Model | KHS350 | KHS400 | KHS450 |

| Motor Power | 55KW | 75KW | 110KW |

| Screw Material | 40CR | 40CR | 40CR |

| Cutting blade | 4pcs,DC53 | 4pcs,DC53 | 4pcs,DC53 |

| Screw diameter | 320mm | 450mm | 550mm |

| Capacity/Hour | 250-350kg/h | 400-600kg/h | 700-1000kg/h |

| Length in mm [A] | 3079 | 3445 | 3811 |

| Height in mm [B] | 2369 | 2657 | 2945 |

| Width in mm[C] | 1720 | 2020 | 2320 |

product Advantage

- Strong screw pressing dewatering design to achieve efficient dewatering;

- Compared with traditional centrifugal dryer, Energy saving up to 70%

- Automatic intelligent control system to achieve accurate control, final moisture content is more uniform.

- Final moisture under 5-8%, it can work together with thermal drying system, moisture can be controlled at 3-5%.

- Easy to operation and Low maintenance.

video