Wholesalemachine Recycling

Product Overview

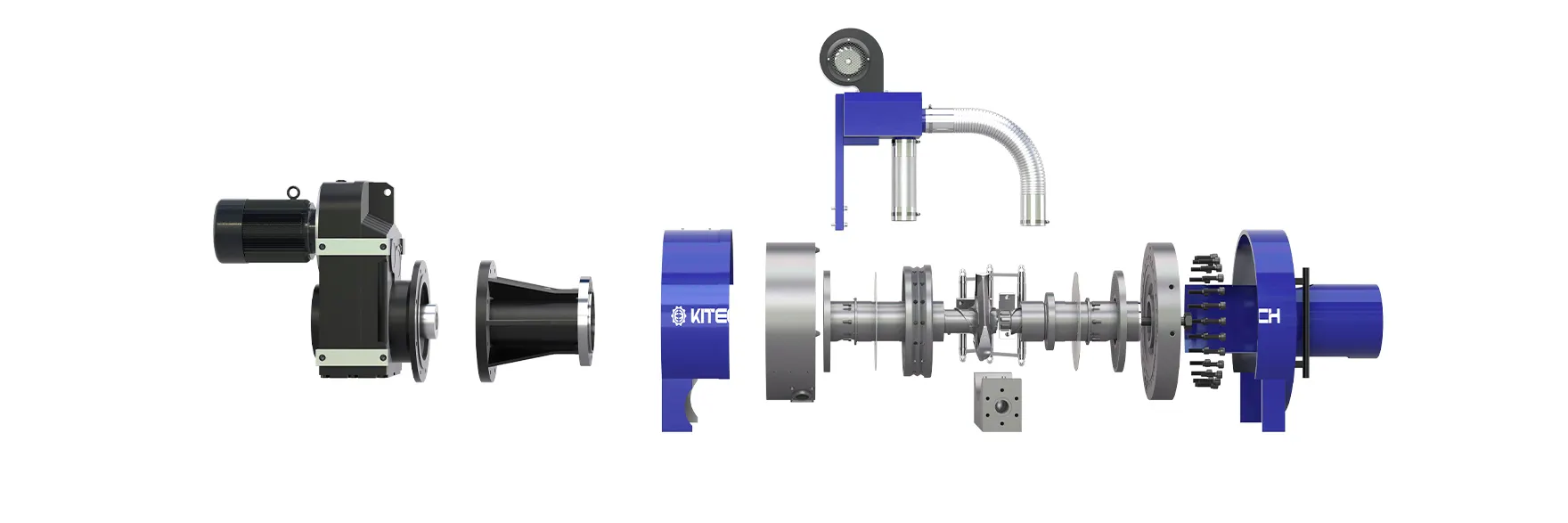

- The Kitech machine recycling is a precise and tested system designed for recycling plastic waste, specifically post-consumer or post-industrial plastic wastes like PP, PE, LDPE, HDPE, PS, and more.

- The Laser Filter is a key component in the Kitech machine recycling, offering high levels of contaminant filtration and resistance to high pressures.

Product Features

- The Laser Filter can be adapted to the material being processed, with a wide range of filtration fineness available, and it improves the quality results of the final product.

- The system is available in different models with varying filter diameters, filter areas, drive power, and throughput capacity, providing flexibility for different application needs.

- The Kitech machine recycling is continuously updated and ready for testing by users, with a focus on providing the best, most convenient, and rapid service for customers.

Product Value

- The system reduces operational and labour costs, as it allows the operator to dedicate more time to efficient feeding of the extruder and does not require frequent filter screen changes.

Product Advantages

- The Kitech machine recycling system offers precise specifications, strict testing, and a strong customer service belief that "the customer is always right."

- The Laser Filter is able to filter out a wide range of contaminants, including metal, paper, cardboard, wood, glass, rubber, and aluminum, from the plastic waste.

Application Scenarios

- The Kitech machine recycling system is suitable for recycling contaminated plastics, such as those with high levels of contaminations that traditional (manual) screen changers are not able to effectively process.

- It can be used in various industries dealing with plastic waste, offering a solution for improving the quality of the final recycled product.