AGH series Plastic Crusher Machine - Kitech

Raw Materials

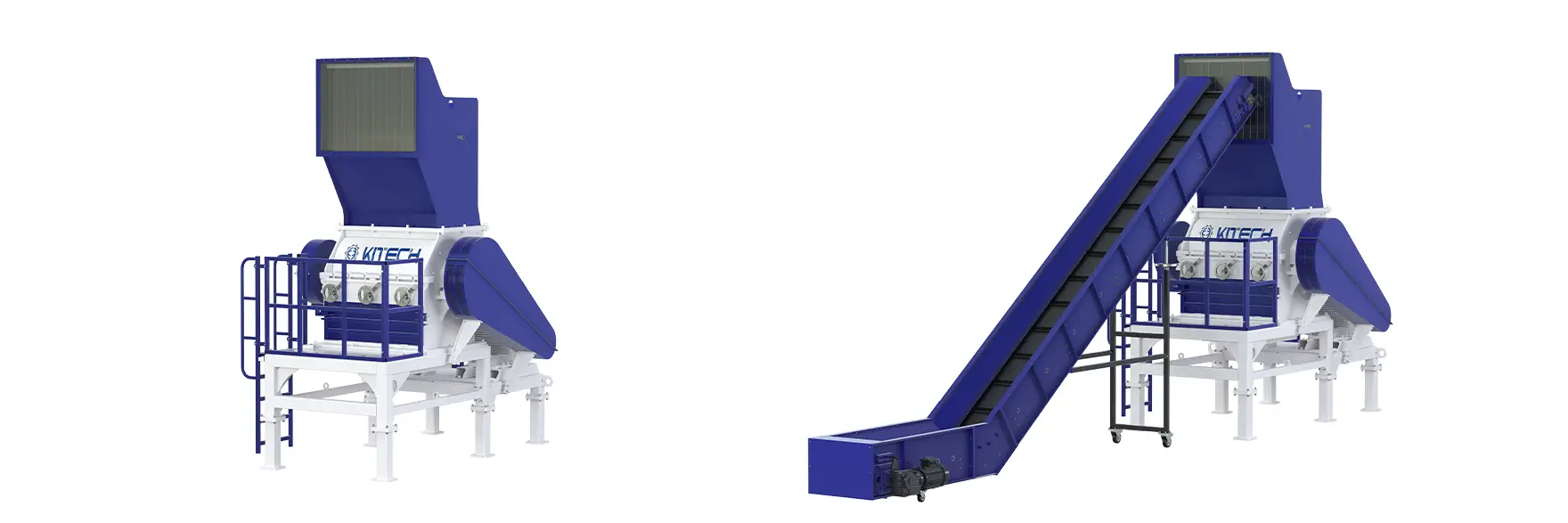

AGH Heavy duty Crusher

The heavy duty granulators of the AGH series offer a wide array of different rotor designs with widths ranging from 500 mm to 2000 mm with a diameter of 350-800mm. Heavy duty vane rotor, welded steel construction, robust crushing chamber, v-mounted Angle, x-cut shape. The extension shaft of the rotor can be equipped with a speed regulating wheel. The adjustable rotor cutter minimizes the stop time of tool changing.The completely welded heavy steel construction is designed to withstand the most demanding and universal applications. Rotor bearings, knife mounts, and rotor shaft are oversized. The standard V-cut creates a high-quality regrind with a very low percentage of fines in the output material. The removable third stator blade is acting as a deflector wedge and allows the machine to be quickly adjusted to different applications. Other standard features include easily replaceable wear plates in the cutting chamber as well as outboard bearings reducing the risk of contamination.

Product Parameters

| ITEM | UNIT | AGH350/500 | AGH500/600 | AGH600/800 | AGH500/1000 | |

| Rotor Diameter | mm | 350 | 500 | 600 | 500 | |

| Rotor Width | mm | 500 | 600 | 800 | 1000 | |

| Rotor Knives | PCs | 3×2/5×2 | 3×2/5×2 | 5×2/7×2 | 3×2/5×2 | |

| Stator Knives | row | 2/3 | 2/3 | 2/3 | 2/3 | |

| Cutting Chamber Dimensions | mm | 516×460 | 636×590 | 790×695 | 985×590 | |

| Motor Power | kw | 15~22 | 37~55 | 55~90 | 55~90 | |

| Dimensions | A | mm | 1800 | 2080 | 2300 | 2230 |

| B | mm | 1600 | 1850 | 2100 | 2000 | |

| C | mm | 1250 | 1530 | 1850 | 1950 | |

| D | mm | 770 | 940 | 1120 | 1350 | |

| E | mm | 2500 | 2620 | 3000 | 2860 | |

| ITEM | UNIT | AGH700/1000 | AGH800/1200 | AGH800/1600 | AGH800/2000 | |

| Rotor Diameter | mm | 700 | 800 | 800 | 800 | |

| Rotor Width | mm | 1000 | 1200 | 1600 | 2000 | |

| Rotor Knives | pcs | 5×217×2/9×2 | 7×2/9×2 | 7×4/9×4 | 7×4/9×4 | |

| Stator Knives | row | 2/3 | 2/3 | 2/3 | 2/3 | |

| Cutting Chamber Dimensions | mm | 985×800 | 1150×915 | 1570×915 | 1960×915 | |

| Motor Power | kw | 75~110 | 110~160 | 132~20 | 160~200×2 | |

| Dimensions | A | mm | 2800 | 3100 | 3140 | 2740 |

| B | mm | 2500 | 2800 | 2800 | 2600 | |

| C | mm | 2060 | 2360 | 2800 | 3460 | |

| D | mm | 1290 | 1530 | 1960 | 2250 | |

| E | mm | 3420 | 3820 | 4250 | 4775 | |

product details

Counterweight wheel

Balance the weight on both sides of main shaft

Bearing

Heavy duty guide bearings and Oversized external bearing housings

Motor

Siemens or WEG motors,High Efficiency,Low Energy Consumption and Reliable.

Electrical hydraulic control

Easy to open housing & screen cradle

Blade

Knives material is high hardness alloy D2, externally adjustable, V-cut technology,Ladder blade rotor configuration for films and hollow plastics

Machine house

Anti-wear machine housing, replaceable wear plates, high strength and toughness,

video