Waste Plastic Washing System - - Kitech

Product Overview

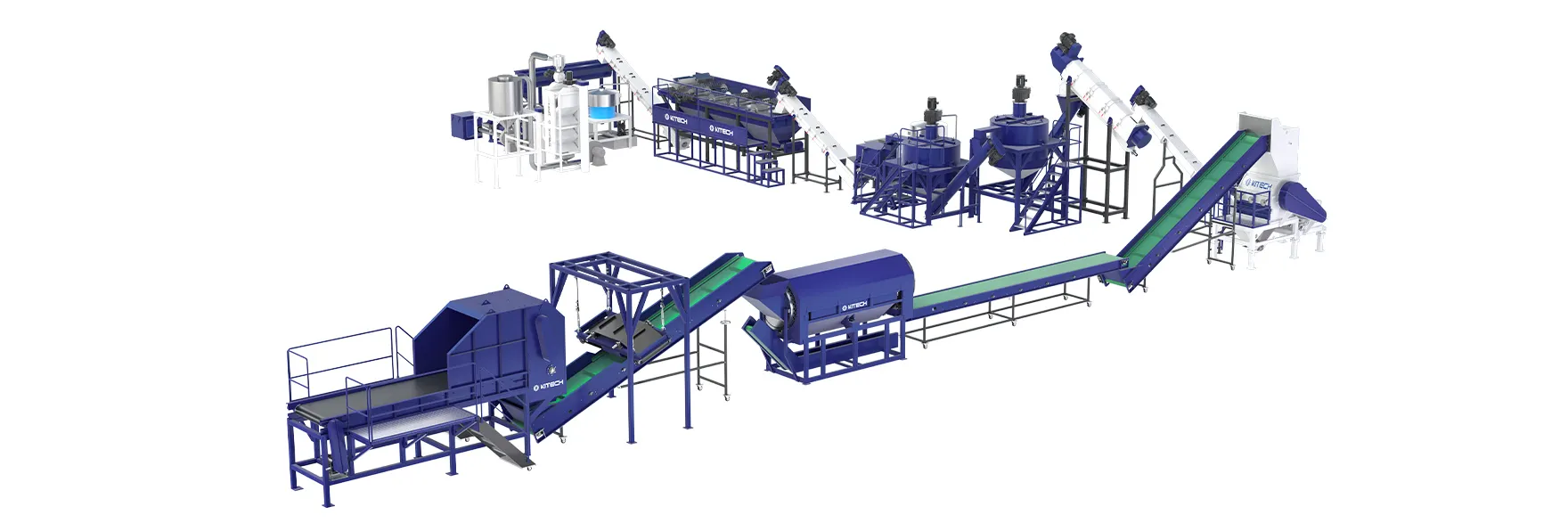

The Waste Plastic Washing System by Kitech is customizable according to customer needs, designed for recycling plastic waste in the daily chemical industry. It includes various plastic packaging containers such as HDPE and PP shampoo bottles, body wash bottles, cosmetics bottles, milk bottles, infusion bottles, HDPE/PP barrels, and boxes.

Product Features

The system includes a belt conveyor, magnetic belt, shredder, washing tank, screw loader, friction washer, crusher, hot washer, centrifugal dryer, hot air pipeline dryer, storage buffer, and PLC controller. The system is designed for efficient grading, crushing, and washing for clean and reusable materials.

Product Value

The system contributes to the circular economy by preparing materials for recycling and reducing environmental impact. It has a capacity ranging from 500 kg/h to 5,000 kg/h, with high efficiency treatment techniques to improve recycling efficiency. The system also removes contaminants and other plastics from materials for downstream use.

Product Advantages

The system is designed with heavy-duty materials and components, such as stainless steel screws, wear-resistant materials, high-speed dynamic balance treatment, and robust construction for durability and efficiency. It includes features like frequency control, easy maintenance, excellent washing effectiveness, and low noise design.

Application Scenarios

The Waste Plastic Washing System is suitable for applications in the daily chemical industry for recycling plastic waste, such as shampoo bottles, body wash bottles, cosmetics bottles, milk bottles, infusion bottles, HDPE/PP barrels, and boxes. It can be used for separating contaminants and preparing materials for downstream processing in a variety of recycling scenarios.