Plastic Waste Recycling Equipment Forsale

Product Overview

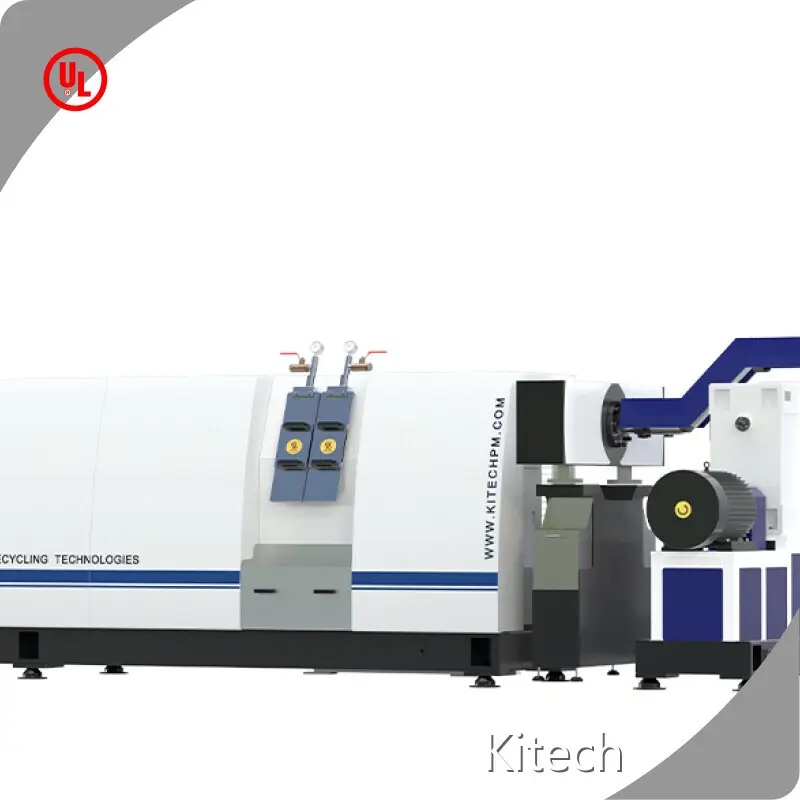

- Kitech plastic waste recycling equipment is made with advanced technology and undergoes strict quality tests before loading.

- The product is extensively demanded in the market due to its unsurpassable advantages.

Product Features

- The KSP series double stage pelletizing machine is specialized for rigid plastic scrap, combining functions of raw materials feeding, plasticization, granulating, and drying.

- Machine capacity per hour ranges from 200-1200KG/H for various raw materials like HDPE, LDPE, PP, PS, ABS, PET, and PA.

- The machine is equipped with various systems like screw loader, single screw extruder, vacuum degassing, filter, pelletizer, water cooling device, dehydration section, and more.

- Pelletizing types include water-ring pelletizing, water-strands pelletizing, and under-water pelletizing.

- Provided services include turn key recycling solution design, production, factory installation, commission, and machine maintenance.

Product Value

- The machine warranty is 1 year, and certificates like CE and UL are provided.

- The system composition and optimized design minimize downtime and save maintenance time.

- The modular design simplifies planning and accelerates implementation, with low consumption values for electricity, water, and labor.

Product Advantages

- The machine has high efficiency barrel and screw for excellent plasticizing result and high output capacity.

- The double chamber design of the degassing system allows for non-stop operation to improve plastic pellets quality.

- Both plate type and piston type filtration systems are provided for better maintenance and screen lifetime.

- The auto-clean filter reduces manual labor for screen changer and regulates waste discharge according to pressure.

Application Scenarios

- The plastic waste recycling equipment is suitable for after crushing/shredding rigid flakes like PP, PE, ABS, PS, HIPS, PC, etc.

- The final pellets/granules produced can be used for injection molding, film blowing, pipe extrusion applications.

- Kitech's products are sold well in Asia, Europe, and other regions due to their high quality, making them suitable for various recycling scenarios worldwide.