Plastic Recycling Pelletizing Machine Manufacturing

Product Overview

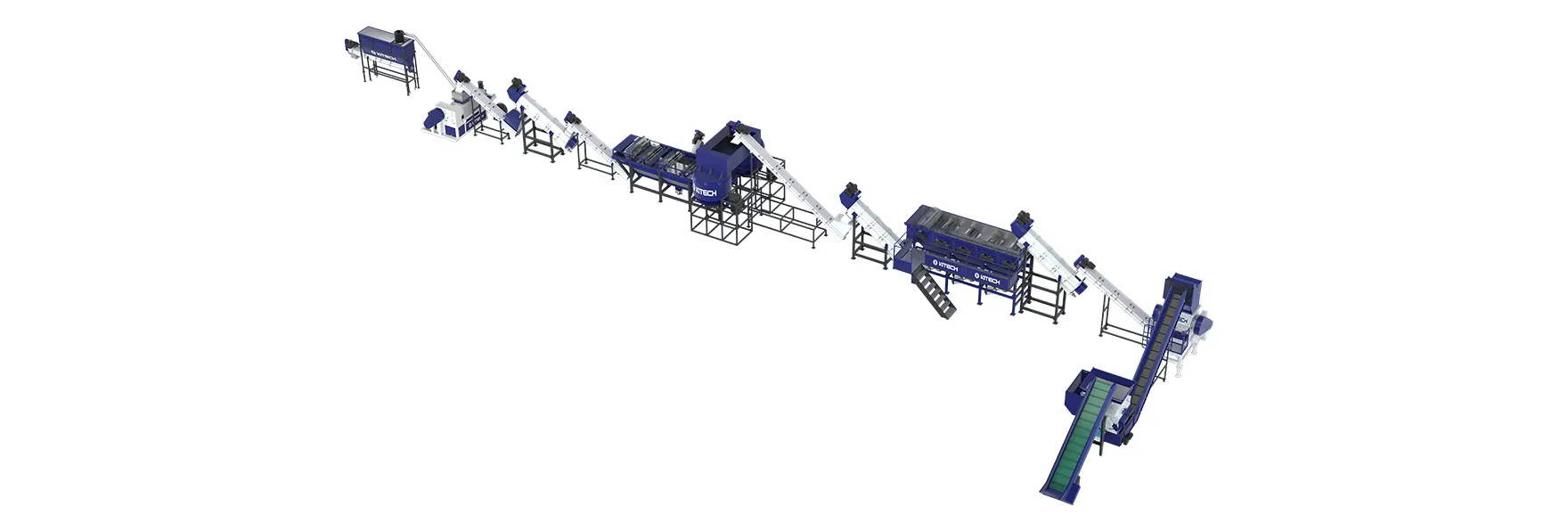

The plastic recycling pelletizing machine manufactured by Kitech is designed for processing LDPE industrial waste film, stretch film, barn bag, and agricultural mulch film. It features a smart modular design that can be customized to cater to the needs of the recycling industry.

Product Features

The machine includes components such as a belt conveyor, metal detector, shredder, washing tank, screw loader, friction washer, crusher, squeezer, storage buffer, and PLC controller. Each component is designed to effectively process and clean PE/PP scraps for pelletizing.

Product Value

The machine offers a high capacity ranging from 250-1500 kg/h, with low energy consumption and chemical usage. It is designed with quality materials such as stainless steel, wear-resistant steel, and heavy-duty bearings for durability and efficiency in operation.

Product Advantages

The machine provides efficient separation of contaminants and removal of water from materials, with a high speed dynamic balance treatment for optimal washing results. It also includes a human-machine interface PLC controller for easy operation and real-time monitoring.

Application Scenarios

The plastic recycling pelletizing machine is suitable for recycling facilities, waste management companies, and plastic manufacturing plants that process LDPE and PP materials. It helps to improve the purity of recycled plastics, protect processing equipment, and enhance overall efficiency in recycling operations.