Customize Portable Plastic Recycling Machine

Product Overview

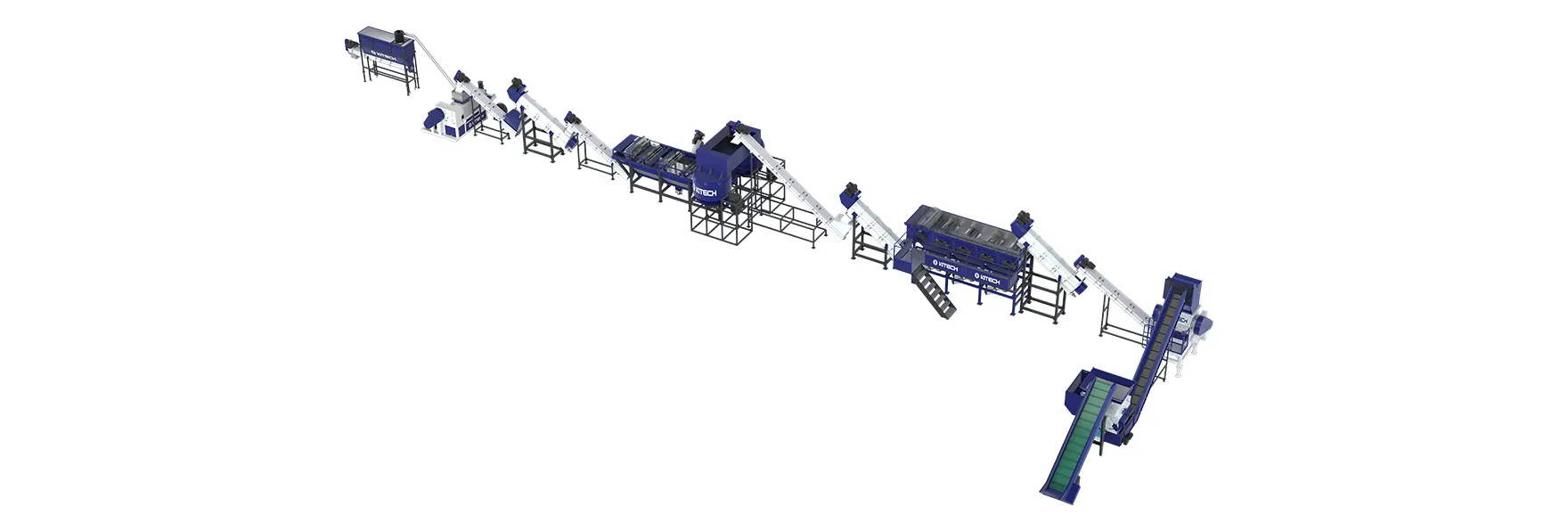

- Kitech offers a portable plastic recycling machine with advanced production and testing equipment.

- The machine is designed for agricultural film, industrial film, and bags and each unit can be combined freely to provide customized solutions.

- The machine has various components such as belt conveyor, metal detector, shredder, washing tank, and more to efficiently recycle plastic materials.

Product Features

- The machine is capable of processing various types of LDPE waste materials such as film, bags, and agricultural mulch film.

- It has a smart modular design for customization and innovation in the recycling process.

- The machine incorporates advanced technologies like a metal detector for improving the quality of recycled plastics.

Product Value

- The portable plastic recycling machine offers high capacity ranging from 250-1500 kg/h.

- It consumes minimal steam, chemicals, energy, and installation power, making it cost-effective and energy-efficient.

- The machine requires only a small workforce of 3-4 persons per shift, reducing labor costs.

Product Advantages

- The machine has a heavy-duty design with durable components like rubber or PVC belt conveyor, solid steel rotor in the shredder, and wear-resistant stainless steel screw loader.

- It offers high-quality washing, friction washing, squeezing, and storage buffering capabilities for efficient recycling.

- The machine is equipped with a PLC controller for easy operation, real-time monitoring, and enhanced automation.

Application Scenarios

- The portable plastic recycling machine is ideal for businesses in the recycling industry looking to process LDPE waste materials efficiently.

- It can be used in agricultural, industrial, and commercial settings to recycle plastic film, bags, and other materials.

- The machine is suitable for companies seeking to improve their sustainability efforts and reduce their environmental impact through plastic recycling.