Best Qualityplastic Washing and Drying Machine

Product Overview

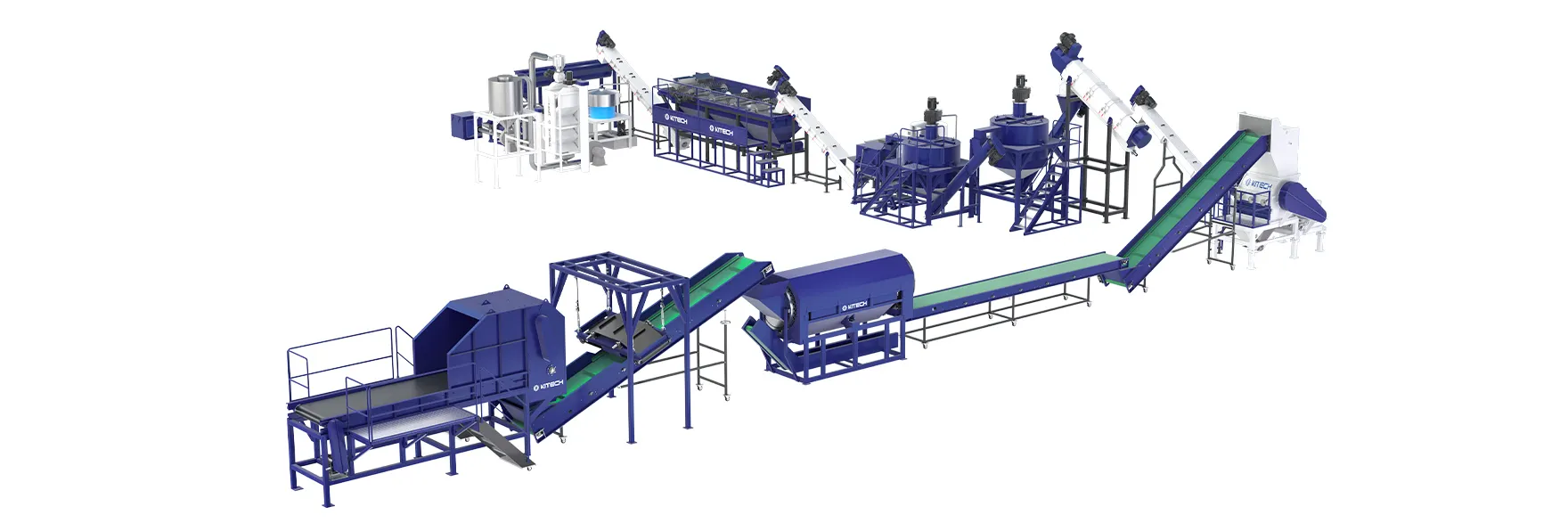

KWPB Series plastic bottles washing machine is designed for recycling plastic waste in the daily chemical industry, including various types of HDPE and PP packaging containers. The production lines effectively wash and prepare materials for recycling, contributing to the circular economy and reducing environmental impact.

Product Features

The RPW series of hard plastic recycling lines have a capacity ranging from 500 kg/h to 5,000 kg/h. The machines utilize high-efficiency treatment techniques to significantly improve recycling efficiency. Various components such as belt conveyors, shredders, washing tanks, and centrifugal dryers are included in the production line.

Product Value

By providing a solution for recycling plastic waste in the daily chemical industry, the plastic washing and drying machine adds value by promoting sustainability, contributing to the circular economy, and reducing environmental impact. It allows for the efficient processing and cleaning of plastic materials for downstream use.

Product Advantages

The plastic washing and drying machine offers advantages such as advanced technology, high efficiency, and high-quality production. The machines are designed to effectively wash, separate, and prepare materials for recycling, ensuring clean and reusable materials for downstream applications.

Application Scenarios

The plastic washing and drying machine is suitable for recycling HDPE and PP plastic waste from various daily chemical industry products such as shampoo bottles, body wash bottles, cosmetics bottles, milk bottles, infusion bottles, barrels, and boxes. The machine can handle a wide range of materials and is designed to cater to different recycling needs.