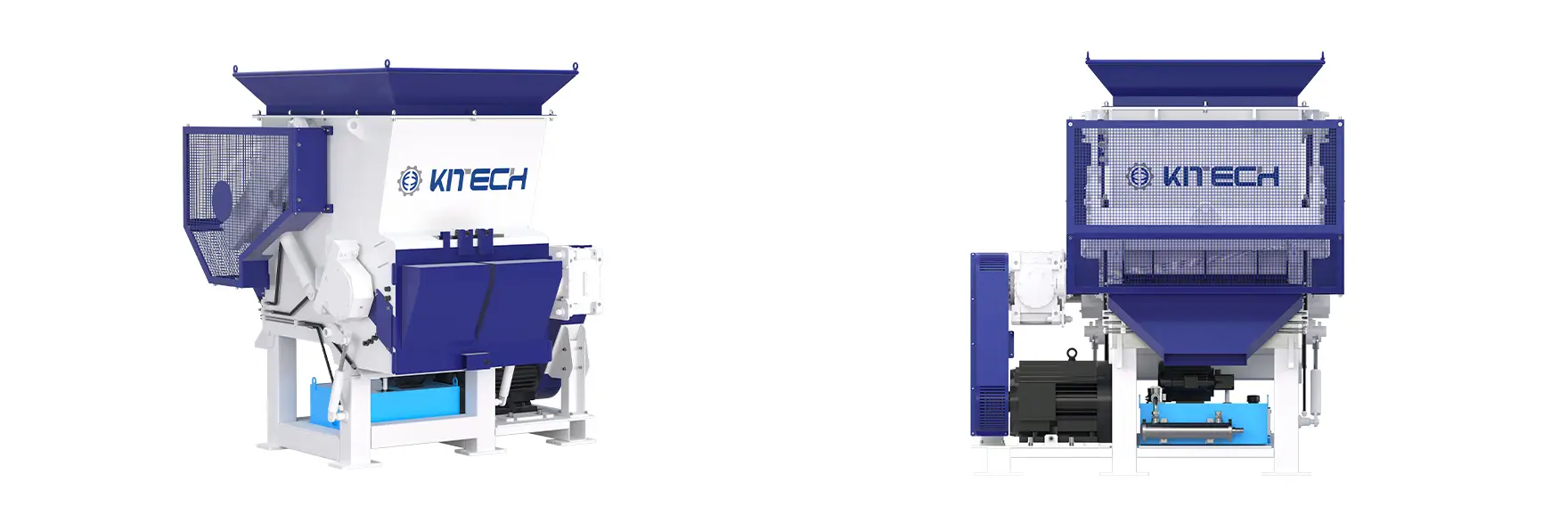

AGSS Shredder - Plastic Shredder machine

Raw Materials

Based on the AGS single shaft shredder, we have enlarged the rotor diameter to better handle high strength materials , such as stretch film and ton bags etc.

AGSS shredder equipped with a powerful swing-type hydraulic pusher.This design effectively prevents blockages, reducing wear on internal guides. Its hydraulic power station is closely integrated with the shredder's chamber, saving space while protecting the hydraulic station and facilitating maintenance. All AGS series models are equipped with an E-type smooth rotor, and the external bearing housing design is based on a hydraulic sieve frame, ensuring safety and reliability with dual practicality.

Product Parameters

| TEM | UNT | AG5850 | AGS120 | AGS1500 | AG52000 | |

| Cutting Chamber | mm | 840x1570 | 1120x1570 | 1400x1570 | 1960x1570 | |

| Rolor Diameter | mm | 588 | 588 | 588 | 588 | |

| Rolor Spee | rpm | 53 | 53 | 53 | 53 | |

| Main Motor Power | kw | 55 | 75 | 90 | 90*2 | |

| Rolor Knives | Pcs | 60 | 81 | 102 144 | ||

| Stator Knives | Pcs | 2x3 | 2x4 | 2x5 | 2x7 | |

| Hydraulic Ram Power | kw | 3.75 | 5.6 | 5.6 | 5.6 | |

| Screen Size | mm | 40~100 | 40~100 | 40~100 | 40~100 | |

| Screen Working Area | mm | 800x730 | 800x1000 | 800x1290 | 800x1860 | |

| Dimensions | A | mm | 2300 | 2300 | 2300 | 2300 |

| B | mm | 1650 | 1650 | 1650 | 1650 | |

| C | mm | 540 | 540 | 540 | 540 | |

| D | mm | 660 | 660 | 660 | 660 | |

| E | mm | 2250 | 2250 | 2250 | 2250 | |

| F | mm | 350 | 350 | 350 | 350 | |

| G | mm | 2000 | 2280 | 2600 3720 | ||

product details

Rotor

Large diameter flat rotor with solid steel

Bearing

Heavy duty guide bearings and bearing housings

Gearbox

Low speed, high torque geared drive

Motor

Siemens or WEG motors,High Efficiency,Low Energy Consumption and Reliable.

Hydraulic ram

Powerful swing type hydraulic pusher to effectively avoid material blockage

Hopper

Special designed hopper to avoid material flying out

Screen

The screen mounted beneath the rotor determines the size of the required flakes. Z-type and O-type screens can be selected according to the material

PLC controller

PLC control system, Flexibility and Programmability,Ease of Maintenance and Troubleshooting.

video