Why Are Plastic Shredder Machines Essential For Industrial Recycling?

Are you curious about the importance of plastic shredder machines in industrial recycling processes? Look no further! In this article, we will delve into the critical role that these machines play in ensuring the efficiency and sustainability of plastic recycling. Whether you are a business owner, environmental enthusiast, or simply interested in learning more about the impact of plastic shredder machines, this article will provide valuable insights into their essential role in the recycling industry. Join us as we explore the benefits and significance of plastic shredder machines in industrial recycling.

Understanding the Importance of Industrial Recycling

Industrial recycling plays a crucial role in conserving resources, reducing waste, and minimizing environmental impact. One of the key technologies essential for industrial recycling is the plastic shredder machine. These powerful machines are designed to efficiently shred plastic waste into smaller pieces, making it easier to recycle and reuse. This article delves into the importance of industrial recycling and the role that plastic shredder machines play in this process.

Industrial recycling is a critical component of sustainable waste management. By recycling materials such as plastic, metal, and paper, industries can significantly reduce their environmental footprint and contribute to a more circular economy. Plastic waste, in particular, has become a major concern due to its widespread use and the detrimental effects it has on the environment. As such, it is essential for industries to invest in the right technology to effectively manage and recycle plastic waste.

Plastic shredder machines are an indispensable tool in the recycling industry. These machines are designed to shred plastic waste into smaller, more manageable pieces, which can then be processed and reused in the manufacturing of new products. The shredding process not only reduces the volume of plastic waste but also prepares the material for further recycling, ultimately preventing it from ending up in landfills or polluting the environment.

There are several key reasons why plastic shredder machines are essential for industrial recycling. Firstly, these machines help to increase the efficiency of the recycling process. By shredding plastic waste into small, uniform pieces, the recycling facilities can process larger quantities of material in a shorter amount of time. This not only improves productivity but also reduces the overall cost of recycling.

Additionally, plastic shredder machines play a crucial role in ensuring the quality of recycled plastic. Through shredding, the plastic waste is cleaned and stripped of any contaminants, such as dirt, labels, or other materials. This results in a higher quality of recycled plastic, which can be used to manufacture a wide range of products, including packaging, containers, and construction materials.

Furthermore, plastic shredder machines contribute to environmental sustainability. By efficiently shredding plastic waste, these machines help to reduce the amount of plastic ending up in landfills or being incinerated. This, in turn, minimizes the environmental impact of plastic pollution and conserves valuable resources. Additionally, the use of recycled plastic in manufacturing reduces the demand for virgin plastic, leading to a decrease in the consumption of fossil fuels and the release of greenhouse gases.

In conclusion, industrial recycling is imperative for sustainable waste management, and plastic shredder machines are essential for effectively managing plastic waste. These machines play a pivotal role in increasing the efficiency of the recycling process, ensuring the quality of recycled plastic, and contributing to environmental sustainability. By investing in and utilizing plastic shredder machines, industries can actively participate in the conservation of resources, reduction of waste, and mitigation of environmental impact.

The Role of Plastic Shredder Machines in Recycling Processes

Plastic waste has become a growing concern in recent years, with a significant impact on the environment and human health. To mitigate this issue, recycling processes have become essential in helping to reduce the amount of plastic waste in landfills and oceans. One crucial component of industrial recycling is the plastic shredder machine, which plays a key role in breaking down plastic materials into smaller, more manageable pieces for further processing. In this article, we will explore the importance of plastic shredder machines in recycling processes and their impact on the environment.

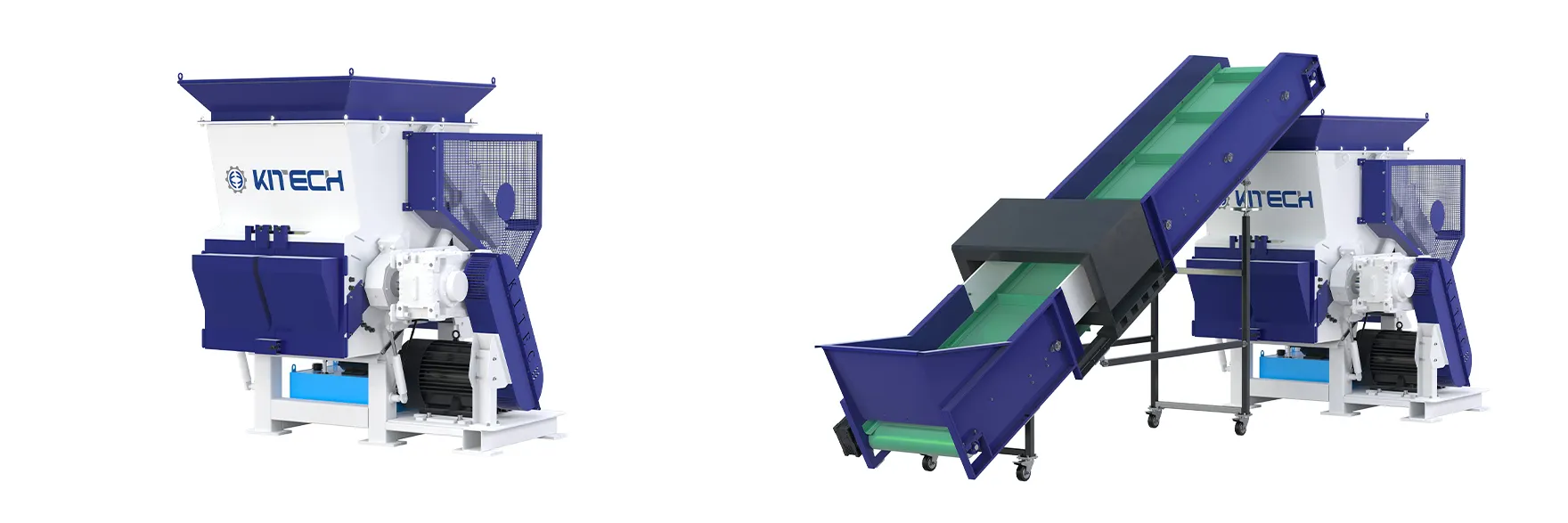

Plastic shredder machines are essential for industrial recycling due to their ability to efficiently break down large plastic items into smaller fragments. These machines utilize strong rotating blades to cut and shred plastic materials, such as bottles, containers, and packaging, into smaller pieces. This process makes the plastic easier to handle and transport, as well as prepares it for subsequent recycling processes, such as melting and molding into new products.

One of the primary benefits of using plastic shredder machines in recycling processes is the reduction of plastic waste volume. By breaking down large plastic items into smaller pieces, the overall volume of plastic waste is significantly reduced, making it easier to store and transport for recycling. This decrease in volume also helps to maximize the efficiency of recycling facilities, as they can process larger quantities of plastic materials in a more compact space.

Additionally, the use of plastic shredder machines contributes to the overall sustainability of recycling processes. By effectively shredding plastic waste, these machines enable recycling facilities to repurpose the material for the production of new plastic products. This closed-loop system reduces the need for the extraction and production of new plastic materials, ultimately conserving natural resources and reducing the environmental impact of plastic production.

Furthermore, plastic shredder machines play a crucial role in improving the quality of recycled plastic materials. By shredding plastic items into smaller, more uniform pieces, these machines help to remove contaminants and impurities from the plastic, resulting in higher-quality recycled materials. This, in turn, allows for the production of new plastic products with improved strength and durability, contributing to the overall sustainability of the plastic recycling industry.

In conclusion, plastic shredder machines are essential for industrial recycling processes due to their ability to efficiently break down plastic waste into smaller, more manageable pieces. These machines play a critical role in reducing the volume of plastic waste, improving the sustainability of recycling processes, and enhancing the quality of recycled plastic materials. As the demand for sustainable and environmentally-friendly solutions continues to grow, the importance of plastic shredder machines in recycling processes cannot be overstated. By investing in these essential machines, recycling facilities can significantly contribute to the reduction of plastic waste and the preservation of our environment for future generations.

Advantages of Using Plastic Shredder Machines in Industrial Recycling

Plastic Shredder Machines are essential tools for industrial recycling due to their numerous advantages in the process of plastic waste management. These machines are designed to efficiently shred plastic materials into smaller pieces, reducing the volume of the waste and preparing it for further processing. In this article, we will discuss the various benefits of using plastic shredder machines in industrial recycling.

One of the primary advantages of using plastic shredder machines is the reduction in waste volume. By shredding plastic materials into smaller pieces, the overall volume of the waste is significantly reduced, making it easier to handle and transport. This reduction in volume also helps in minimizing the storage space required for the waste, leading to cost savings for the recycling facilities.

Furthermore, plastic shredder machines play a crucial role in the recycling process by preparing the waste for further processing. The shredded plastic materials can be easily fed into other recycling machinery such as granulators, extruders, and injection molding machines for the production of new plastic products. This seamless integration with other recycling equipment streamlines the entire recycling process, making it more efficient and cost-effective.

In addition to reducing waste volume and facilitating the recycling process, plastic shredder machines also help in achieving environmental sustainability. By shredding plastic waste, these machines contribute to the reduction of landfill usage and the conservation of natural resources. The shredded plastic materials can be used as raw materials for the production of new plastic products, reducing the demand for virgin plastic and minimizing the environmental impact of plastic production.

Another significant advantage of using plastic shredder machines is the ability to process various types of plastic materials. These machines are designed to shred a wide range of plastic materials, including PET bottles, HDPE containers, PVC pipes, and more. This versatility makes plastic shredder machines an invaluable asset in industrial recycling, as they can effectively handle different types of plastic waste, making the recycling process more comprehensive and efficient.

Moreover, plastic shredder machines are also equipped with safety features to ensure the protection of the operators and the integrity of the recycling process. These machines are designed with advanced safety mechanisms to prevent accidents and ensure smooth operation. Additionally, some models are equipped with automatic shut-off systems and overload protection to prevent damage to the machine and ensure continuous operation.

In conclusion, the advantages of using plastic shredder machines in industrial recycling are undeniable. These machines play a crucial role in reducing waste volume, preparing plastic waste for further processing, promoting environmental sustainability, and processing various types of plastic materials. With their efficiency, versatility, and safety features, plastic shredder machines are essential tools for modern industrial recycling facilities. By incorporating these machines into their operations, recycling facilities can improve their waste management processes and contribute to a more sustainable future.

Impact of Plastic Shredder Machines on Environmental Sustainability

Plastic pollution has become a major environmental concern in recent years, as the proliferation of single-use plastics has led to a significant increase in plastic waste. This has put a strain on our natural ecosystems, and has led to a decrease in environmental sustainability. As a result, industrial recycling has become an essential component of combating the plastic pollution crisis, and plastic shredder machines have emerged as a critical tool in this effort.

The impact of plastic shredder machines on environmental sustainability cannot be overstated. These machines play a crucial role in the recycling process by breaking down plastic waste into smaller, more manageable pieces. This not only reduces the volume of plastic waste, but also makes it easier to handle and transport for further processing. By shredding plastic waste, these machines make it possible to convert it into new products, reducing the need for virgin materials and the associated environmental impact of their extraction and production.

Furthermore, plastic shredder machines also contribute to reducing the carbon footprint of the recycling process. By shredding plastic waste on-site at recycling facilities, the need for long-distance transportation to centralized shredding facilities is eliminated, cutting down on fuel consumption and greenhouse gas emissions. This decentralized approach to plastic shredding not only reduces the environmental impact of recycling, but also makes the process more cost-effective and efficient.

Another important aspect of the impact of plastic shredder machines on environmental sustainability is their role in promoting a circular economy. By shredding plastic waste and turning it into reusable materials, these machines support the principles of a circular economy, in which resources are used and reused in a closed loop, minimizing waste and maximizing the value of materials. This helps to conserve natural resources, reduce energy consumption, and minimize the environmental impact of plastic production and disposal.

Additionally, plastic shredder machines also contribute to mitigating the negative impact of plastic pollution on wildlife and natural ecosystems. By reducing the volume of plastic waste and preventing it from entering the environment, these machines help to protect marine life, birds, and other wildlife from the harmful effects of plastic pollution. This in turn supports the long-term sustainability of ecosystems, and helps to preserve biodiversity and the health of natural habitats.

In conclusion, plastic shredder machines are essential for industrial recycling and play a vital role in promoting environmental sustainability. Their ability to reduce the volume of plastic waste, minimize the carbon footprint of recycling, support a circular economy, and mitigate the impact of plastic pollution makes them an indispensable tool in the fight against plastic pollution. As the global community continues to grapple with the challenges of plastic waste, the use of plastic shredder machines will be increasingly important in advancing environmental sustainability and creating a more sustainable future for generations to come.

Future Trends in Industrial Recycling Technology: The Role of Plastic Shredder Machines

Plastic waste has become a significant environmental concern worldwide, leading to an urgent need for effective recycling solutions. As a result, industrial recycling technology has seen significant advancements in recent years, with the role of plastic shredder machines taking center stage in the effort to address the plastic waste crisis.

Plastic shredder machines play a crucial role in the recycling industry by effectively breaking down plastic waste into smaller, more manageable pieces. This process not only reduces the volume of plastic waste but also prepares it for further processing and recycling. In fact, the future trends in industrial recycling technology are increasingly reliant on the use of plastic shredder machines to streamline the recycling process and maximize the recovery of valuable resources from plastic waste.

One of the key trends in industrial recycling technology is the development of advanced plastic shredder machines that are capable of handling various types of plastic waste. These machines are designed to accommodate the diverse nature of plastic materials, including rigid plastics, films, and other forms of plastic packaging. By incorporating cutting-edge technologies and innovative features, modern plastic shredder machines are able to efficiently process different types of plastic waste, thereby increasing the overall effectiveness of the recycling process.

Furthermore, the role of plastic shredder machines in industrial recycling extends beyond mere waste reduction. These machines also play a critical role in preparing plastic waste for various recycling processes, such as extrusion, injection molding, and other manufacturing applications. By shredding plastic waste into uniform pieces, plastic shredder machines enable manufacturers to produce high-quality recycled plastic products with consistent properties and performance.

In addition to traditional mechanical shredding, future trends in industrial recycling technology are exploring alternative methods for shredding plastic waste, such as chemical and thermal processes. These innovative approaches offer new opportunities for improving the efficiency and sustainability of plastic recycling, while also addressing the challenges associated with certain types of plastic materials that may be difficult to shred using conventional methods.

Moreover, the widespread adoption of plastic shredder machines in industrial recycling is driving the development of comprehensive recycling systems that optimize the entire recycling process, from collection and sorting to shredding and reprocessing. This holistic approach enables recyclers to achieve higher overall recycling rates and reduce the environmental impact of plastic waste by maximizing the recovery of valuable resources from discarded plastics.

As the demand for recycled plastic continues to grow, the role of plastic shredder machines in industrial recycling is poised to become even more essential in the coming years. With ongoing advancements in technology and a greater focus on sustainability, plastic shredder machines are set to play a pivotal role in shaping the future of industrial recycling, driving innovation, and paving the way for a more circular and sustainable approach to plastic waste management.

In conclusion, plastic shredder machines are undeniably essential for industrial recycling, as they enable the efficient processing of plastic waste, facilitate the production of high-quality recycled materials, and drive the advancement of future trends in recycling technology. As the demand for sustainable and cost-effective recycling solutions continues to rise, the role of plastic shredder machines will only become more crucial in addressing the plastic waste challenge and contributing to a more environmentally responsible approach to plastic recycling.

Conclusion

In conclusion, plastic shredder machines play a crucial role in the industrial recycling process for several reasons. Firstly, they help to reduce the size of plastic waste, making it easier to handle and transport for recycling. Additionally, shredder machines aid in the separation of different types of plastics, ensuring that they can be effectively sorted and recycled. Furthermore, the use of shredder machines can contribute to the overall sustainability of industrial operations, as they promote a more efficient and eco-friendly approach to managing plastic waste. Ultimately, the integration of plastic shredder machines into industrial recycling processes is essential for effectively reducing plastic pollution and promoting a more sustainable future.