How To Troubleshoot Common Issues With Plastic Shredder Machines

Are you tired of dealing with constant issues with your plastic shredder machine? Look no further! In this comprehensive guide, we will walk you through the most common problems that can arise with plastic shredder machines and provide you with practical troubleshooting tips to help you get your machine back up and running smoothly. Whether you're a seasoned professional or just starting out, this article is a must-read for anyone looking to get the most out of their plastic shredder machine. So, grab a cup of coffee and dive into our expert advice to keep your plastic shredder running like a well-oiled machine.

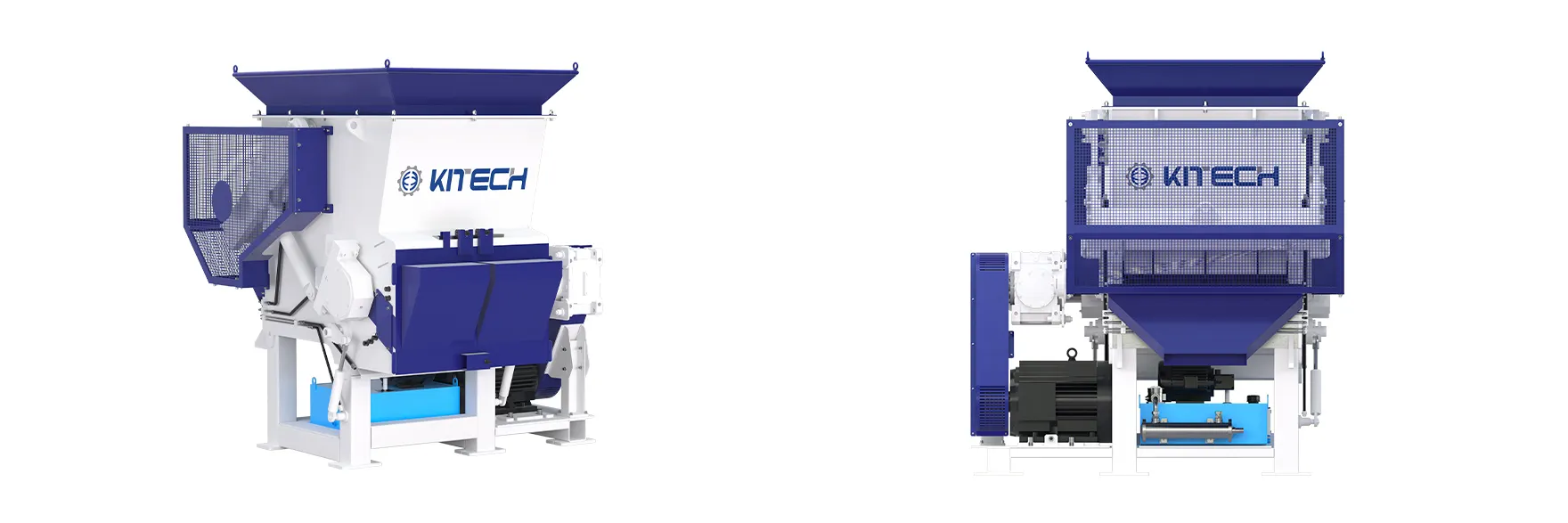

Understanding the Function and Components of Plastic Shredder Machines

Plastic shredder machines are used in a variety of industries to efficiently break down plastic materials into smaller, more manageable pieces. These machines play a critical role in the recycling process, as they help to reduce the size of plastic waste, making it easier to transport and process. In order to effectively troubleshoot common issues with plastic shredder machines, it is important to have a thorough understanding of their function and components.

Understanding the function of a plastic shredder machine is essential to effectively troubleshooting any issues that may arise. These machines are designed to shred plastic materials into small, uniform pieces, making them easier to handle and process. The shredding process begins with the feeding of plastic materials into the machine, where they are then cut and torn by rotating blades. The shredded plastic is then collected and can be further processed for recycling or disposal.

The components of a plastic shredder machine are crucial to its overall function and performance. These machines typically consist of a hopper, where the plastic materials are fed into the machine, a cutting chamber, where the actual shredding takes place, and a discharge chute, where the shredded plastic is collected. The cutting chamber is the heart of the machine, housing the rotating blades that actually shred the plastic materials. In addition to these main components, plastic shredder machines also contain motors, transmission systems, and control panels to regulate the shredding process.

When troubleshooting common issues with plastic shredder machines, it is important to start by inspecting the various components for any signs of damage or wear. The blades, in particular, should be checked for dullness or damage, as this can significantly impact the machine's shredding performance. In some cases, the blades may need to be sharpened or replaced in order to restore the machine's efficiency.

Another common issue with plastic shredder machines is clogging, which can occur when the machine becomes overloaded with plastic materials. This can cause the machine to jam and result in decreased shredding efficiency. To troubleshoot this issue, it is important to carefully inspect the feeding mechanism and make any necessary adjustments to prevent overloading. Additionally, regular maintenance and cleaning of the machine can help to prevent clogging and ensure smooth operation.

In conclusion, a thorough understanding of the function and components of plastic shredder machines is essential for effectively troubleshooting common issues. By carefully inspecting the machine's components and identifying any signs of damage or wear, it is possible to address issues such as blade dullness and clogging. With proper maintenance and attention to detail, plastic shredder machines can continue to operate efficiently and contribute to the recycling process.

Identifying Common Issues and Potential Causes

Plastic shredder machines are important equipment used in waste management and recycling facilities. They are designed to shred plastic materials into smaller pieces for easier processing and recycling. However, like any other machinery, they are prone to common issues that can affect their performance. This article will discuss how to identify these common issues and their potential causes, as well as provide troubleshooting tips to address them.

One common issue with plastic shredder machines is jamming. This occurs when the plastic material gets stuck in the shredder, preventing it from functioning properly. There are several potential causes of jamming, including overloading the machine with too much plastic, using the wrong type of plastic, or having dull blades. To troubleshoot this issue, it is important to first turn off the machine and unplug it to ensure safety. Then, carefully remove the jammed material and inspect the blades for any signs of damage or dullness. If the blades are dull, they will need to be sharpened or replaced. Additionally, be sure to use the appropriate type and amount of plastic in the shredder to prevent jamming in the future.

Another common issue with plastic shredder machines is overheating. This can occur when the machine is operated for long periods of time without proper cooling or maintenance. Overheating can lead to damage to the machine's motor or other components. To troubleshoot this issue, it is important to first allow the machine to cool down completely before restarting it. Additionally, check the machine's cooling system, such as the fan and vents, to ensure they are clean and functioning properly. It is also important to regularly lubricate the machine's moving parts to prevent overheating and reduce friction.

In addition to jamming and overheating, another common issue with plastic shredder machines is unusual noises during operation. These noises can be a sign of worn or damaged parts, such as the blades, bearings, or motor. To troubleshoot this issue, it is important to first identify the source of the noise by carefully listening to the machine while it is in operation. Once the source of the noise is identified, the worn or damaged parts will need to be repaired or replaced. Regular maintenance, such as lubrication and blade sharpening, can help prevent unusual noises and ensure the machine's smooth operation.

In conclusion, plastic shredder machines are essential equipment for waste management and recycling facilities. However, they are susceptible to common issues such as jamming, overheating, and unusual noises. By identifying these common issues and their potential causes, as well as implementing effective troubleshooting tips, operators can ensure the proper functioning of their plastic shredder machines. Regular maintenance and proper operation practices are key to preventing these common issues and optimizing the performance of plastic shredder machines.

Steps to Take in Troubleshooting Performance Problems

Plastic Shredder machines are essential tools in the recycling industry, but like any machinery, they can encounter performance problems from time to time. Troubleshooting these issues is essential in ensuring smooth operations and preventing downtime. In this article, we will discuss the steps to take in troubleshooting performance problems with plastic shredder machines in order to keep them running efficiently.

Step 1: Identify the Problem

The first step in troubleshooting performance problems with a plastic shredder machine is to identify the specific issue. Common performance problems may include unusual noises, decreased throughput, or uneven shredding. By thoroughly examining the machine and observing its operation, you can pinpoint the root of the problem.

Step 2: Check for Mechanical Issues

Once the problem has been identified, the next step is to check for any mechanical issues that may be causing the performance problem. This may include inspecting the blades for wear or damage, checking for loose or damaged belts, and ensuring that all moving parts are properly lubricated. Additionally, it is important to inspect the motor and gearbox for any signs of malfunction.

Step 3: Evaluate the Material Being Shredded

Sometimes, performance problems with a plastic shredder machine can be attributed to the type of material being shredded. Certain materials may be too dense or too thick for the machine to handle, causing it to work harder and leading to decreased performance. In such cases, it may be necessary to adjust the shredder’s settings or consider using a different type of shredder for the specific material.

Step 4: Review Safety Measures

In some cases, performance problems with a plastic shredder machine may be a result of safety concerns. Ensuring that all safety guards and interlocks are properly in place and functioning is essential for the safe and efficient operation of the machine. Additionally, it is crucial to provide proper training to the machine operators to prevent any misuse that could lead to performance issues.

Step 5: Regular Maintenance

Preventative maintenance is key in avoiding performance problems with a plastic shredder machine. Regularly scheduled maintenance, including blade sharpening or replacement, checking for loose bolts, and cleaning out any debris or buildup, can help to keep the machine running smoothly and prevent performance issues from arising.

Step 6: Seek Professional Assistance

If the performance problem with the plastic shredder machine persists despite troubleshooting efforts, it may be necessary to seek professional assistance. A qualified technician can provide a comprehensive inspection of the machine, diagnose the issue, and perform any necessary repairs or adjustments to get the machine back to optimal performance.

In conclusion, troubleshooting performance problems with a plastic shredder machine requires a systematic approach, from identifying the problem to taking appropriate measures to address it. By following the steps outlined in this article, operators and maintenance personnel can effectively troubleshoot and resolve performance issues, ensuring that the plastic shredder machine continues to operate efficiently in the recycling process.

Maintenance and Cleaning Techniques to Prevent Future Issues

Plastic shredder machines are an essential piece of equipment in many manufacturing and recycling facilities. They are used to break down plastic waste into smaller, more manageable pieces, which can then be processed and recycled into new products. However, like any piece of machinery, plastic shredder machines can develop issues over time that can affect their performance and efficiency. In this article, we will discuss some common issues that may arise with plastic shredder machines and provide maintenance and cleaning techniques to prevent future problems.

One common issue that may arise with plastic shredder machines is jamming. This occurs when the plastic waste becomes stuck in the cutting mechanism, preventing the machine from effectively shredding the material. To prevent jamming, it is important to regularly inspect the shredder blades for any signs of wear or damage. If the blades are dull or worn out, they should be replaced as soon as possible to ensure that the machine can continue to operate efficiently.

In addition to regular blade maintenance, it is also important to keep the shredder machine clean and free of debris. Over time, dust, dirt, and other contaminants can build up in the machine, which can affect its performance and lead to jamming. To prevent this, the machine should be thoroughly cleaned on a regular basis, paying particular attention to the cutting chamber and blades. This can be done using a brush or compressed air to remove any built-up debris.

Another common issue with plastic shredder machines is overheating. This can occur when the machine is operated for long periods of time without proper cooling or when the blades become dull and start to generate excess heat. To prevent overheating, it is important to monitor the machine's temperature regularly and ensure that it is not being operated for extended periods without a break. Additionally, the cutting chamber should be lubricated regularly to reduce friction and heat generation.

Finally, another common issue with plastic shredder machines is that they can become clogged with plastic residue, which can affect their performance. To prevent this, it is important to regularly clean out the cutting chamber and remove any built-up plastic waste. This can be done using a brush or scraper to dislodge the residue and a vacuum to remove it from the machine.

In conclusion, plastic shredder machines are an important piece of equipment in many manufacturing and recycling facilities. However, they can develop issues over time that can affect their performance and efficiency. By regularly inspecting and maintaining the shredder blades, keeping the machine clean and free of debris, monitoring its temperature, and preventing clogs, these issues can be minimized, and the machine can continue to operate effectively. By following these maintenance and cleaning techniques, future issues with plastic shredder machines can be prevented, ensuring that they continue to play a vital role in the recycling and manufacturing process.

Seeking Professional Assistance for Complex Shredder Machine Repairs

Plastic shredder machines are essential equipment for recycling and waste management facilities. These machines are designed to shred plastic waste into smaller pieces for recycling or disposal. However, like any other industrial equipment, plastic shredder machines are prone to various mechanical and operational issues.

In this article, we will discuss the common issues that can arise with plastic shredder machines and provide troubleshooting tips. We will also cover the importance of seeking professional assistance for complex shredder machine repairs.

Common Issues with Plastic Shredder Machines

1. Jamming: One of the most common issues with plastic shredder machines is jamming. This occurs when the plastic material gets stuck in the shredder blades, preventing them from operating properly. Jamming can be caused by overloading the machine, using the wrong type of plastic, or worn-out blades.

To troubleshoot this issue, it is important to first turn off the machine and disconnect it from the power source. Then, carefully remove the jammed material from the blades using a tool or by hand. After clearing the jam, inspect the blades for any damage or wear and replace them if necessary.

2. Overheating: Another common issue with plastic shredder machines is overheating, which can be caused by prolonged use or a lack of proper maintenance. Overheating can lead to damage to the machine's motor and other components.

To prevent overheating, it is important to follow the manufacturer's recommended operating guidelines and schedule regular maintenance for the machine. This includes cleaning and lubricating the blades, checking for loose or worn-out parts, and ensuring proper ventilation for the machine.

3. Uneven Shredding: Sometimes, plastic shredder machines may produce unevenly shredded material, which can be attributed to dull or damaged blades, uneven feed, or misalignment of the shredder components.

To troubleshoot this issue, it is important to inspect the shredder blades for any damage or wear and replace them if necessary. Additionally, check the feed mechanism for any obstructions or misalignments and make the necessary adjustments to ensure even feeding of the plastic material.

Seeking Professional Assistance for Complex Shredder Machine Repairs

While the troubleshooting tips mentioned above can help address common issues with plastic shredder machines, there are instances where complex repairs may be required. In such cases, it is important to seek professional assistance from qualified technicians or service providers.

Professional technicians have the expertise and experience to diagnose and repair complex issues with plastic shredder machines. They also have access to specialized tools and equipment needed to effectively troubleshoot and repair the machines.

When seeking professional assistance for shredder machine repairs, it is important to choose a reputable service provider with a track record of providing quality repairs and maintenance services for industrial equipment. Additionally, it is important to inquire about the technician's experience and qualifications, as well as the availability of genuine replacement parts for the machine.

In conclusion, plastic shredder machines are essential equipment for recycling and waste management facilities, but they can experience common issues such as jamming, overheating, and uneven shredding. While troubleshooting tips can help address these issues, seeking professional assistance for complex shredder machine repairs is crucial to ensure the longevity and optimal performance of the equipment. By choosing a reputable service provider with qualified technicians, facility managers can ensure that their plastic shredder machines are in good working condition.

Conclusion

In conclusion, troubleshooting common issues with plastic shredder machines is an essential aspect of maintaining a smooth and efficient operation. By following the steps outlined in this article, you can identify and address issues such as jamming, overheating, and dull blades to keep your machine running at its best. Remember to perform regular maintenance and cleaning to prevent problems from arising, and always consult the manufacturer's guidelines for specific troubleshooting tips. By staying proactive and addressing issues promptly, you can extend the lifespan of your plastic shredder machine and ensure consistent, high-quality performance for years to come. Happy shredding!