Can A Plastic Shredder Machine Save You Time In Your Production Process?

Are you looking for ways to streamline your production process and increase efficiency? Look no further than a plastic shredder machine. In this article, we will explore how a plastic shredder machine can save you time and optimize your production process. If you’re interested in maximizing productivity and reducing waste in your operations, keep reading to discover the benefits of incorporating a plastic shredder machine into your workflow.

- Understanding the Role of Plastic Shredder Machines in Production Processes

Plastic shredder machines have become an integral part of the production process in many industries. These machines play a crucial role in breaking down plastic waste into smaller pieces, which can then be recycled and used to create new products. In this article, we will explore the various ways in which plastic shredder machines can save time and improve efficiency in production processes.

One of the key benefits of using a plastic shredder machine in production processes is the ability to reduce the volume of plastic waste. By breaking down plastic materials into smaller pieces, these machines can significantly reduce the amount of space needed for storage and transportation of plastic waste. This, in turn, can lead to cost savings and improved efficiency in the production process.

Furthermore, plastic shredder machines can also help to improve the overall environmental impact of production processes. By recycling and reusing plastic waste, companies can reduce their reliance on virgin plastic materials, which in turn can help to conserve natural resources and reduce the carbon footprint of their operations.

Another important advantage of using plastic shredder machines in production processes is the ability to save time and labor. These machines are designed to efficiently and effectively shred plastic materials, reducing the amount of manual labor required for this task. This, in turn, can free up valuable time and resources that can be allocated to other aspects of the production process, ultimately leading to improved productivity and cost savings.

In addition, the use of plastic shredder machines can also help to enhance the overall quality of the products being produced. By using recycled plastic materials, companies can create products that are more sustainable and environmentally friendly, which can be an attractive selling point for customers. Furthermore, the use of shredded plastic materials can also lead to the development of new and innovative products, further enhancing the competitive edge of companies in the market.

In conclusion, the role of plastic shredder machines in production processes cannot be overstated. These machines play a crucial role in reducing the volume of plastic waste, improving the environmental impact of production processes, saving time and labor, and enhancing the overall quality of products. As the demand for sustainable and environmentally friendly products continues to grow, the use of plastic shredder machines will undoubtedly become increasingly important in the production processes of companies across various industries.

- Time-saving Benefits of Using a Plastic Shredder Machine

In today’s fast-paced manufacturing environment, every minute counts. Companies are constantly seeking ways to improve efficiency and streamline their production processes. One tool that has become increasingly popular in the manufacturing industry is the plastic shredder machine. This innovative piece of equipment offers a wide range of time-saving benefits that can make a significant impact on a company’s bottom line.

One of the main time-saving benefits of using a plastic shredder machine is its ability to reduce the size of plastic waste materials quickly and efficiently. Instead of manually cutting and breaking down large pieces of plastic, the shredder machine can do the job in a fraction of the time. This not only saves valuable time but also eliminates the need for manual labor, reducing the risk of repetitive strain injuries for employees.

Furthermore, a plastic shredder machine can process various types of plastic materials, including PET bottles, PVC pipes, and plastic containers, with ease. This versatility means that companies can consolidate their plastic shredding needs into one machine, saving time and space in the production facility. Instead of relying on multiple pieces of equipment for different types of plastic waste, a single shredder machine can handle it all.

In addition to reducing the size of plastic waste, a shredder machine can also help to facilitate the recycling process, saving time and resources. By shredding plastic materials into smaller, more manageable pieces, the recycling process becomes more efficient. These shredded materials can then be easily transported to a recycling facility, where they can be repurposed into new products. This not only saves time but also aligns with companies’ sustainability goals, reducing their environmental impact.

Another time-saving benefit of using a plastic shredder machine is the reduction in downtime and maintenance. Modern shredder machines are designed to be durable and reliable, minimizing the need for frequent repairs and maintenance. This means that companies can spend less time on equipment upkeep and more time focusing on their production processes.

Furthermore, some shredder machines are equipped with advanced automation features, further increasing their time-saving benefits. These automated systems can process plastic waste materials with minimal human intervention, allowing employees to focus on other tasks. Additionally, the automation of the shredding process can significantly reduce the risk of human error, further saving time and resources.

The time-saving benefits of using a plastic shredder machine extend beyond the production process itself. By streamlining the waste management and recycling process, companies can save time and money in the long run. Furthermore, the use of a shredder machine can improve the overall efficiency of a company’s operations, leading to increased productivity and profitability.

In conclusion, the time-saving benefits of using a plastic shredder machine are undeniable. From reducing the size of plastic waste materials to facilitating the recycling process, a shredder machine can make a significant impact on a company’s production processes. By investing in this innovative piece of equipment, companies can save time, resources, and money, ultimately improving their bottom line.

- Integration of Plastic Shredder Machines into Your Production Line

In today’s fast-paced and competitive manufacturing industry, efficiency is key. Companies are constantly looking for ways to streamline their production processes and reduce waste, in order to stay ahead of the competition. One solution that has gained popularity in recent years is the integration of plastic shredder machines into production lines. These machines are designed to quickly and efficiently shred plastic waste, making it easier to recycle and reuse materials, and ultimately saving time and money in the production process.

Plastic shredder machines are designed to handle a wide range of plastic materials, including PET, PVC, HDPE, and more. This versatility makes them an ideal solution for companies that work with various types of plastic in their production processes. With the ability to quickly and effectively shred plastic waste, these machines can significantly reduce the amount of time and labor required to handle and process plastic materials, allowing companies to focus on their core production activities.

One of the key benefits of integrating a plastic shredder machine into a production line is the reduction of waste. By shredding plastic waste on-site, companies can significantly reduce the amount of plastic sent to landfills, and instead, recycle and reuse the materials in their production processes. This not only helps to reduce the environmental impact of production but can also lead to cost savings, as companies can purchase fewer raw materials and spend less on waste disposal.

Additionally, plastic shredder machines can also help companies to improve their overall production efficiency. By streamlining the handling and processing of plastic materials, these machines can help to reduce downtime and increase productivity. With the ability to quickly shred plastic waste, companies can ensure that their production lines run smoothly and efficiently, without the need for frequent interruptions to handle waste materials.

Furthermore, the integration of a plastic shredder machine into a production line can also help companies to meet sustainability and environmental goals. With the ability to recycle and reuse plastic materials, companies can reduce their reliance on virgin plastics, and ultimately reduce their carbon footprint. This can be particularly important for companies looking to improve their corporate social responsibility and appeal to environmentally conscious consumers.

When considering the integration of a plastic shredder machine into a production line, it’s important to choose a machine that is well-suited to the specific needs of the company. Factors to consider include the size and capacity of the machine, the types of plastic materials it can handle, and the level of automation and control features it offers. By carefully selecting a machine that meets the company’s specific requirements, companies can ensure that they are able to fully maximize the benefits of integrating a plastic shredder machine into their production line.

In conclusion, the integration of plastic shredder machines into production lines can offer a wide range of benefits for companies in the manufacturing industry. From reducing waste and improving efficiency to meeting sustainability and environmental goals, these machines can play a crucial role in helping companies to streamline their production processes and stay ahead of the competition. As the demand for sustainable and efficient production solutions continues to grow, the integration of plastic shredder machines is becoming an increasingly popular choice for companies looking to improve their operations.

- Maximizing Efficiency and Productivity with Plastic Shredder Machines

In today's fast-paced manufacturing environment, maximizing efficiency and productivity is essential for staying competitive. One way to achieve this is by incorporating plastic shredder machines into your production process. These machines are designed to efficiently shred plastic materials, resulting in several time-saving and cost-effective benefits for businesses.

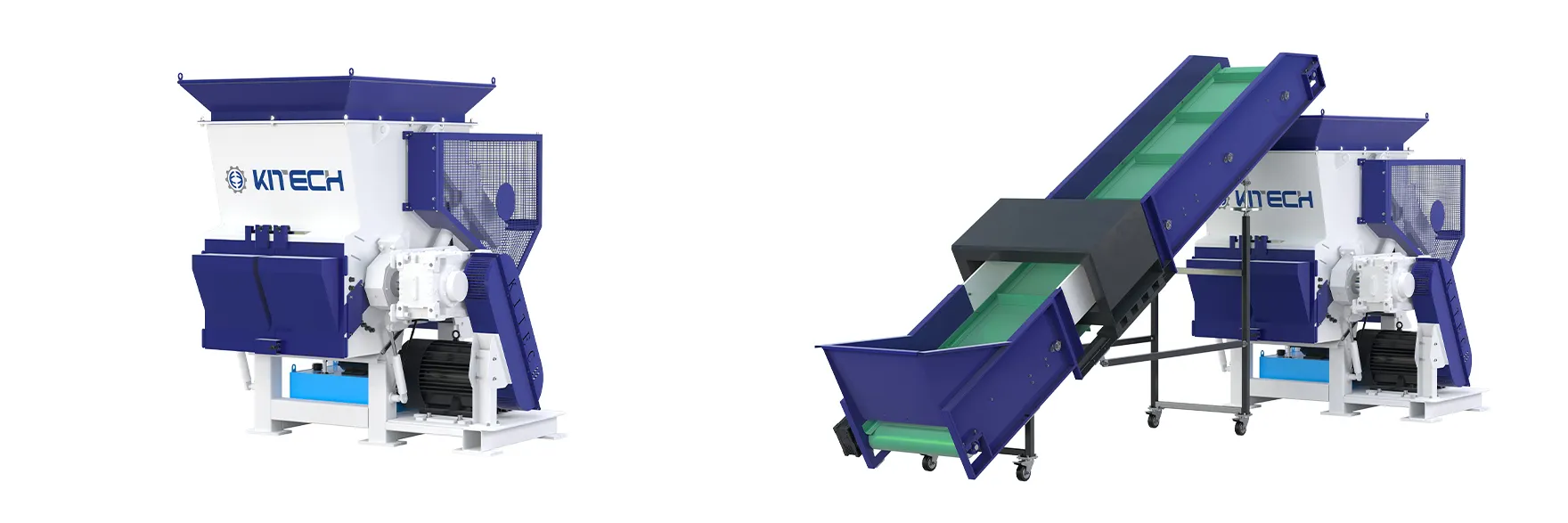

Plastic shredder machines are advanced industrial equipment that can effectively reduce the size of plastic waste, such as bottles, jugs, containers, and other products made of plastic. The shredders are equipped with powerful rotating blades that cut the plastic into small pieces, making it easier to handle and transport for recycling or disposal.

One of the key benefits of using a plastic shredder machine is the time it saves in the production process. Instead of manually cutting and breaking down plastic materials, the machine can quickly and efficiently shred them in a fraction of the time. This not only speeds up the production process but also reduces the labor and resources required for handling plastic waste.

Furthermore, plastic shredder machines can also help businesses save money by reducing the amount of waste generated. By shredding plastic materials, businesses can compact and store the shredded plastic more efficiently, saving on storage space and transportation costs. Additionally, the shredded plastic can be sold to recycling companies, providing an additional revenue stream for businesses.

In addition to saving time and money, plastic shredder machines also contribute to environmental sustainability. By effectively shredding plastic waste, businesses can reduce their environmental footprint and support a more circular economy. By recycling shredded plastic, businesses can contribute to the creation of new products while reducing the need for new plastic production.

When it comes to choosing a plastic shredder machine, businesses should consider several factors. These include the type and volume of plastic waste generated, the required shredding capacity, and the size and space available for the machine. There are various types of plastic shredder machines available, including single shaft shredders, double shaft shredders, and even shredder granulator combinations.

It's important to invest in a high-quality plastic shredder machine that can handle the specific needs of your business. This includes considering factors such as the material of the blades, the motor power, and the safety features of the machine. Additionally, businesses should also consider the maintenance and operational costs of the machine to ensure long-term efficiency and productivity.

Overall, a plastic shredder machine can save businesses time in their production process by efficiently shredding plastic waste. This not only contributes to cost savings and environmental sustainability but also streamlines the production process. By investing in a high-quality plastic shredder machine, businesses can maximize efficiency and productivity while contributing to a more sustainable future.

- Considerations for Choosing the Right Plastic Shredder Machine for Your Production Needs

Plastic Shredder Machine: Considerations for Choosing the Right One for Your Production Needs

In the fast-paced world of manufacturing, efficiency is key. Finding ways to streamline your production process can save you time and money in the long run. One tool that may help in this endeavor is a plastic shredder machine. These machines are designed to break down large plastic materials into smaller, more manageable pieces, making them easier to handle and process. However, with the wide variety of shredder machines available on the market, it can be challenging to determine which one is best suited for your specific production needs. In this article, we will explore some key considerations for choosing the right plastic shredder machine for your production needs.

The first consideration when selecting a plastic shredder machine is the type of plastic material you will be processing. Different types of plastics have varying levels of density and strength, which require different levels of shredding power. For example, thin plastic films may require a different shredder machine than thick plastic sheets or rigid plastic containers. It is essential to understand the specific properties of the plastic materials you will be shredding to ensure that the machine you choose can handle the job efficiently.

Another crucial consideration is the capacity of the shredder machine. The capacity of a shredder machine refers to the amount of plastic material it can process within a given amount of time. If your production process involves a high volume of plastic waste, you will need a shredder machine with a higher capacity to keep up with demand. On the other hand, if your production process involves a lower volume of plastic waste, a smaller capacity shredder machine may be sufficient. Understanding the volume of plastic material you will be processing is essential in determining the right capacity for your shredder machine.

The size and space requirements of the shredder machine are also important factors to consider. Depending on the layout of your production facility, you may have limited space available for a shredder machine. Some shredder machines are designed to be more compact and have a smaller footprint, making them suitable for tight spaces. On the other hand, if you have ample space available, you may opt for a larger shredder machine with higher capacity. It is crucial to assess the available space in your production facility and choose a shredder machine that fits your space requirements.

Additionally, the maintenance and operating costs of the shredder machine should be taken into account. Some shredder machines may require more frequent maintenance and have higher operating costs, while others may be more cost-effective in the long run. It is important to consider the long-term maintenance and operating expenses of the shredder machine to ensure that it remains a valuable asset to your production process.

In conclusion, a plastic shredder machine can be a valuable addition to your production process, helping to save time and improve efficiency. When choosing the right shredder machine for your production needs, it is essential to consider the type of plastic material, capacity, size and space requirements, as well as maintenance and operating costs. By carefully evaluating these factors, you can select a shredder machine that meets your specific production needs and helps streamline your manufacturing process.

Conclusion

In conclusion, a plastic shredder machine can indeed save you time in your production process. By efficiently shredding and reducing plastic waste, these machines can streamline your operations and increase productivity. Additionally, the shredded plastic material can be reused or recycled, making it an environmentally-friendly solution as well. Investing in a plastic shredder machine can ultimately lead to cost savings, improved efficiency, and a more sustainable production process. So if you're looking to boost your manufacturing capabilities and reduce waste, consider incorporating a plastic shredder machine into your operations. Your bottom line and the environment will thank you.