Which Plastic Shredder Machine Is Ideal For HDPE Shredding?

Are you looking for the perfect plastic shredder machine for shredding HDPE? Look no further! In this article, we will explore the various types of shredder machines available and help you determine which one is the ideal choice for shredding high-density polyethylene (HDPE) plastic. Whether you are a small business or an industrial operation, finding the right machine is crucial for efficient and effective recycling. Join us as we delve into the world of plastic shredder machines and uncover the best option for your HDPE shredding needs.

- Understanding the Importance of HDPE Shredding

Plastic shredder machines are a critical tool for recycling and waste management, and understanding the importance of HDPE shredding is essential for choosing the right machine for this specific type of plastic. HDPE, or high-density polyethylene, is a versatile and widely used plastic that is commonly found in milk jugs, detergent bottles, and other containers. Its durability and strength make it a popular choice for packaging and other applications, but its environmental impact can be significant if not properly managed.

The importance of HDPE shredding lies in the need to efficiently and effectively recycle this type of plastic to reduce waste and minimize environmental harm. Plastic shredder machines are designed to break down plastic waste into smaller pieces, making it easier to process and recycle. HDPE shredding is particularly important because of the high demand for recycled HDPE in the manufacturing of new products. By shredding HDPE plastic waste, it can be transformed into reusable raw materials for the production of new items, reducing the need for virgin plastic and minimizing the environmental impact of plastic production.

When it comes to choosing the ideal plastic shredder machine for HDPE shredding, there are several factors to consider. The type of shredder, the size and capacity of the machine, and the specific requirements for processing HDPE plastic all play a role in determining the best option for a particular application. Single shaft shredders, dual shaft shredders, and granulators are all common types of plastic shredder machines, each with its own advantages and limitations.

Single shaft shredders are a versatile and efficient option for HDPE shredding, capable of handling large volumes of plastic waste and producing consistently sized output. Dual shaft shredders offer even greater power and flexibility, able to process a wider range of materials and produce smaller, more uniform particles. Granulators are another popular choice for HDPE shredding, particularly for applications that require finely ground plastic particles for further processing.

In addition to the type of shredder, the size and capacity of the machine are important considerations for HDPE shredding. The volume of plastic waste to be processed, the desired output size, and the specific requirements for recycling and reusing the shredded material all play a role in determining the ideal machine for the job. For large-scale industrial applications, a high-capacity shredder with a powerful motor and robust construction may be necessary, while smaller operations or specialized recycling facilities may benefit from a more compact and efficient shredding solution.

Ultimately, the ideal plastic shredder machine for HDPE shredding will depend on the specific needs and goals of the recycling or waste management operation. By understanding the importance of HDPE shredding and considering the various factors involved in choosing the right machine, businesses and organizations can make informed decisions that promote efficient and sustainable plastic recycling. With the right plastic shredder machine in place, HDPE plastic waste can be effectively processed and recycled, contributing to a more sustainable and environmentally friendly approach to plastic waste management.

- Factors to Consider When Choosing a Plastic Shredder Machine for HDPE

When it comes to shredding HDPE (High-Density Polyethylene) plastics, choosing the right plastic shredder machine is crucial. Not all shredders are created equal, and there are several factors to consider when selecting a machine for HDPE shredding. In this article, we will discuss the key factors to keep in mind when choosing a plastic shredder machine for HDPE.

The first factor to consider is the type of shredding mechanism. There are several types of shredders available, including single shaft, dual shaft, and quad shaft shredders. Each type of shredder has its own advantages and disadvantages, so it's important to consider the specific needs of your HDPE shredding operation. Single shaft shredders are ideal for general-purpose shredding, while dual and quad shaft shredders are better suited for more demanding applications.

Another important factor to consider is the size and capacity of the shredder. The size and capacity of the shredder will depend on the amount of HDPE you need to shred and the size of the material. It's important to choose a shredder that can handle the volume of HDPE you need to process, as well as the size of the material. Additionally, you should consider the space available for the shredder and ensure that it will fit in your facility.

The power and speed of the shredder are also important considerations when choosing a plastic shredder machine for HDPE. The power of the shredder will determine how efficiently it can shred HDPE, while the speed will affect the throughput and productivity of the shredding process. It's important to choose a shredder with the right balance of power and speed to ensure optimal performance.

Durability and maintenance are also key factors to consider when choosing a plastic shredder machine for HDPE shredding. The shredder you choose should be durable enough to withstand the rigors of shredding HDPE, and it should be easy to maintain to ensure optimal performance and longevity. Look for shredders with high-quality materials and construction, as well as easy access for maintenance and cleaning.

Finally, it's important to consider the cost of the shredder and the overall return on investment. While it's important to choose a shredder that meets your specific needs for HDPE shredding, it's also important to consider the cost and value of the machine. Look for a shredder that offers a good balance of performance and cost-effectiveness, and consider the long-term savings and benefits of investing in a high-quality shredder.

In conclusion, choosing the right plastic shredder machine for HDPE shredding requires careful consideration of factors such as the type of shredding mechanism, size and capacity, power and speed, durability and maintenance, and cost. By taking these factors into account, you can select a shredder that meets your specific needs and provides optimal performance for shredding HDPE plastics.

- Comparing Different Types of Plastic Shredder Machines for HDPE Shredding

Plastic shredder machines play a crucial role in the recycling and waste management industry, especially when it comes to shredding high-density polyethylene (HDPE) plastics. With the increasing demand for HDPE recycling, it is essential to have the right plastic shredder machine for efficient and effective shredding. In this article, we will compare different types of plastic shredder machines for HDPE shredding to help you determine which one is ideal for your needs.

Single Shaft Shredder:

The single shaft shredder is a popular choice for HDPE shredding due to its simplicity and versatility. This type of shredder uses a single rotating shaft with multiple blades that cut and shred the plastic into small, uniform pieces. The single shaft shredder is ideal for processing smaller quantities of HDPE, and it is also suitable for other types of plastics and materials. However, it may not be as efficient for larger-scale HDPE shredding operations.

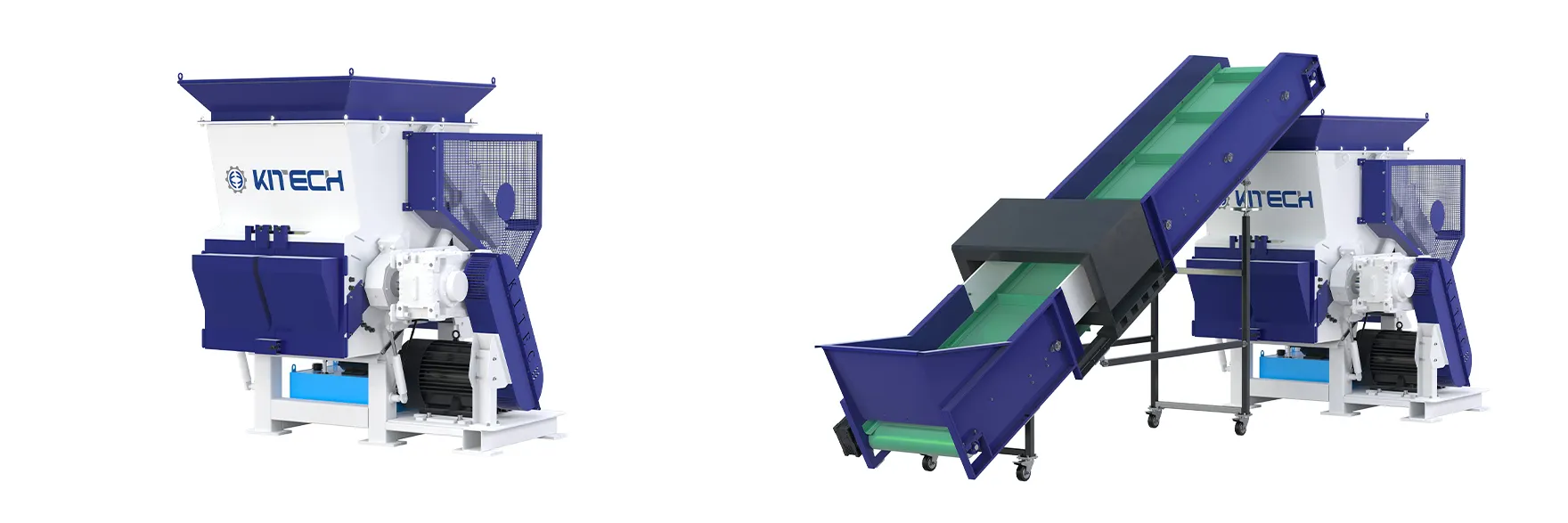

Double Shaft Shredder:

The double shaft shredder is a more robust and heavy-duty option for HDPE shredding. It features two counter-rotating shafts with interlocking blades that work together to shred the plastic into small, consistent pieces. The double shaft shredder is ideal for high-volume HDPE shredding and can handle larger and more rigid plastic materials with ease. This type of shredder is often used in industrial recycling facilities and waste management operations where large quantities of HDPE need to be processed.

Granulators:

Granulators are another type of plastic shredder machine that is commonly used for HDPE shredding. Unlike single and double shaft shredders, granulators use a combination of cutting blades and rotating knives to reduce the plastic material into smaller particles. Granulators are suitable for processing both large and small quantities of HDPE, and they can produce different sizes of shredded plastic depending on the specific needs of the application.

Factors to Consider:

When choosing the ideal plastic shredder machine for HDPE shredding, there are several factors to consider. Firstly, the volume of HDPE material that needs to be shredded will dictate the type and size of shredder required. Additionally, the size and shape of the shredded output, as well as the desired processing speed, will also influence the choice of shredder. It is essential to consider the overall efficiency, maintenance requirements, and operating costs of the shredder to ensure that it meets the specific needs of the operation.

In conclusion, there are several types of plastic shredder machines available for HDPE shredding, each with its own advantages and disadvantages. The choice of the ideal shredder will depend on the specific requirements of the HDPE shredding operation, including the volume of material, desired output size, and processing speed. By comparing different types of plastic shredder machines and considering the important factors, it is possible to select the most suitable shredder for efficient and effective HDPE shredding.

- Key Features to Look for in an Ideal Plastic Shredder Machine for HDPE

When it comes to shredding HDPE (high-density polyethylene) plastic, it’s important to have the right equipment on hand. As the demand for plastic recycling continues to grow, the need for efficient and effective plastic shredder machines has become increasingly important. When shopping for a plastic shredder machine for HDPE shredding, there are several key features to look for in order to ensure that you are getting the best tool for the job.

One of the most important features to consider when looking for a plastic shredder machine for HDPE shredding is the size and power of the machine. HDPE is a strong and durable material, so it requires a machine that can handle its density. Look for a shredder that has a high-powered motor and a sturdy blade system to ensure that it can effectively break down and shred HDPE plastic into small, manageable pieces.

In addition to size and power, it’s important to consider the shredding capacity of the machine. The capacity of a shredder refers to the amount of material it can process at one time. For industrial or commercial use, it’s important to find a machine with a high shredding capacity to ensure that it can keep up with the demands of your operation. Look for a machine that can handle large volumes of HDPE plastic without compromising on performance or efficiency.

Another important feature to look for in a plastic shredder machine for HDPE shredding is the safety and maintenance features. Shredding plastic can be a hazardous task, so it’s important to find a machine that has the necessary safety features in place to protect operators and prevent accidents. Look for features such as emergency stop buttons, safety guards, and automatic shut-off systems to ensure that the machine can be operated safely.

In addition to safety features, it’s also important to consider the maintenance requirements of the machine. Look for a shredder that is designed for easy maintenance, with accessible parts and clear maintenance instructions. Regular maintenance is essential for keeping a shredder in good working condition, so it’s important to find a machine that makes maintenance as simple and straightforward as possible.

Finally, when searching for a plastic shredder machine for HDPE shredding, it’s important to consider the overall quality and durability of the machine. Look for a machine that is built to last, with a strong and robust construction that can withstand the demands of regular use. It’s also important to consider the reputation of the manufacturer and the level of customer support and service that they provide. Investing in a high-quality, durable shredder from a reputable manufacturer can help to ensure that you get a machine that will deliver consistent, reliable performance for years to come.

In conclusion, finding the ideal plastic shredder machine for HDPE shredding involves considering a range of important features. By looking for a machine with the right size and power, a high shredding capacity, safety and maintenance features, and overall quality and durability, you can ensure that you are getting a machine that is well-equipped to handle the demands of shredding HDPE plastic. With the right machine on hand, you can streamline your plastic recycling operation and ensure that you can effectively and efficiently process HDPE plastic for recycling.

- Making an Informed Decision: Choosing the Best Plastic Shredder Machine for HDPE Shredding

Plastic shredder machines have become an indispensable tool in the recycling industry, especially when it comes to shredding high-density polyethylene (HDPE) plastics. With the increasing demand for recycled materials and the emphasis on sustainable waste management, choosing the best plastic shredder machine for HDPE shredding is crucial for businesses and organizations looking to effectively process and recycle plastic waste. In this article, we will explore the key factors to consider when selecting a plastic shredder machine for HDPE shredding, helping you make an informed decision.

Type of Shredder: When it comes to shredding HDPE plastics, it is essential to choose the right type of shredder machine. There are various types of shredders available in the market, including single shaft shredders, double shaft shredders, and granulators. Single shaft shredders are suitable for general-purpose shredding, while double shaft shredders are more robust and suitable for heavy-duty shredding applications. Granulators, on the other hand, are ideal for producing uniform-sized granules of shredded plastic. Assessing your specific shredding needs and the volume of HDPE plastics to be processed will help determine the most suitable type of shredder for your operation.

Shredding Capacity: The shredding capacity of the machine is another critical factor to consider. Depending on the volume of HDPE plastics you need to process, it is essential to choose a shredder machine with the appropriate capacity. Consider factors such as the throughput rate, motor power, and cutting chamber size to ensure that the shredder can handle the required capacity without compromising on performance and efficiency.

Cutting Technology: The cutting technology employed in the shredder machine plays a significant role in determining the quality and consistency of the shredded HDPE plastics. High-quality shredder machines utilize advanced cutting technologies such as rotary cutters, shear cutters, and knife cutters to ensure precise and efficient shredding of plastic materials. Understanding the cutting technology and its impact on the shredding process will help you select a machine that delivers optimal results.

Durability and Maintenance: Investing in a durable and low-maintenance shredder machine is vital to minimize downtime and ensure long-term performance. Look for shredder machines constructed from high-quality materials and equipped with robust components to withstand the rigors of shredding HDPE plastics. Additionally, consider the ease of maintenance and accessibility of spare parts to ensure seamless operation and minimal disruptions.

Safety Features: Safety should always be a top priority when selecting a plastic shredder machine. Look for machines with safety features such as emergency stop buttons, safety locks, and overload protection to protect operators and prevent accidents during operation. Ensuring the safety of your personnel and the integrity of the shredding process is essential for a smooth and risk-free operation.

In conclusion, choosing the best plastic shredder machine for HDPE shredding requires careful consideration of factors such as the type of shredder, shredding capacity, cutting technology, durability and maintenance, and safety features. By evaluating these key factors and understanding your specific shredding needs, you can make an informed decision and select a shredder machine that meets your requirements for efficient and effective HDPE plastic shredding.

Conclusion

In conclusion, finding the ideal plastic shredder machine for HDPE shredding requires careful consideration of factors such as capacity, power, and durability. Whether you opt for a single-shaft shredder, a double-shaft shredder, or a granulator, it's important to prioritize efficiency and quality in order to achieve the best results. Additionally, taking into account the specific requirements of your recycling facility will help you make an informed decision. With the right plastic shredder machine, you can effectively process and recycle HDPE, contributing to a more sustainable future. So, take your time to research and evaluate the different options available to find the ideal machine for your needs.