What Are The Latest Advances In Plastic Shredder Machine Technology?

Are you curious about the latest developments in plastic shredder machine technology? Look no further! In this article, we will explore the most recent advancements in this rapidly evolving field. From improved efficiency to enhanced safety features, we'll delve into the cutting-edge innovations that are revolutionizing plastic shredder machines. Whether you are a business owner looking to upgrade your equipment or a technology enthusiast seeking to stay informed, this article is a must-read. Join us as we uncover the latest advances in plastic shredder machine technology and their potential impact on the industry.

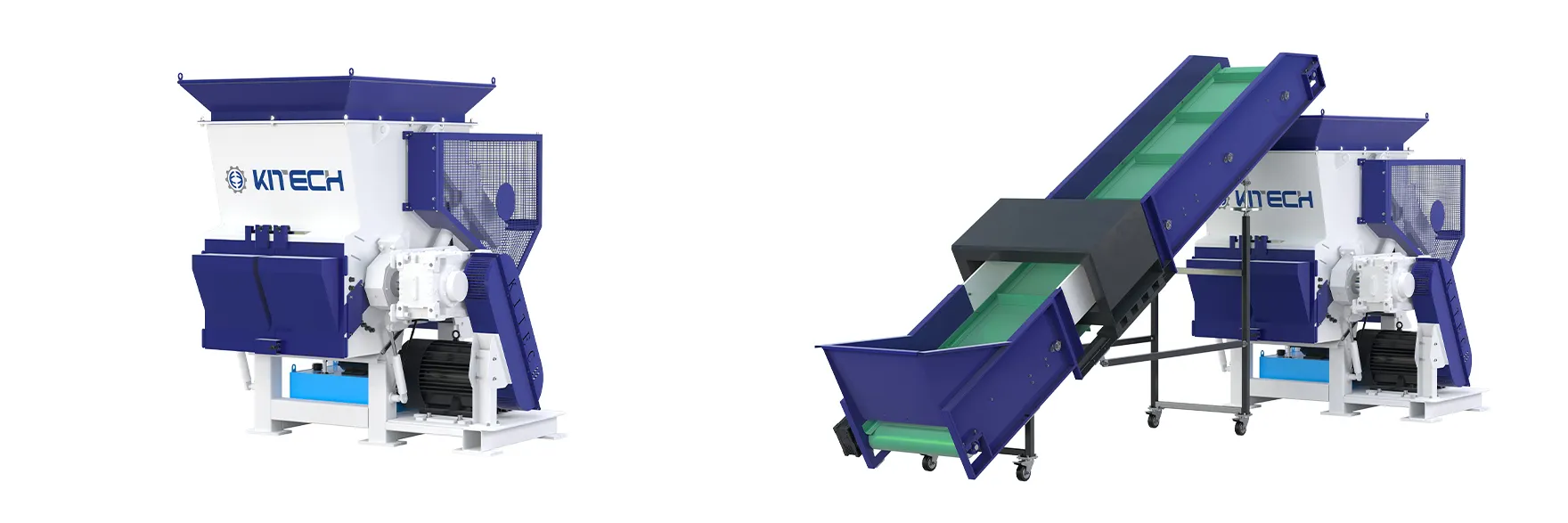

Introduction to Plastic Shredder Machines

Plastic shredder machines have revolutionized the recycling industry, offering an effective and efficient way to process and recycle plastic waste. These machines are designed to shred plastic materials into small, manageable pieces, making it easier to handle and process. With the latest advances in plastic shredder machine technology, the industry is constantly evolving to meet the increasing demand for sustainable waste management solutions.

One of the most significant advancements in plastic shredder machine technology is the development of high-powered and durable shredders. These machines are capable of handling large volumes of plastic waste with ease, making them ideal for industrial and commercial recycling facilities. The use of advanced cutting blades and heavy-duty motors ensures that these shredders can effectively break down even the toughest and most resilient plastic materials.

Another key advancement in plastic shredder machine technology is the integration of advanced automation and control systems. Modern shredders are equipped with sophisticated sensors and monitoring devices that allow for precise control over the shredding process. This ensures that the machines operate at optimal efficiency while minimizing energy consumption and reducing wear and tear on the equipment.

Furthermore, the latest plastic shredder machines are designed to be more versatile and adaptable to different types of plastic waste. These machines can process a wide range of plastic materials, including PET bottles, PVC pipes, plastic drums, and more. This versatility makes it easier for recycling facilities to handle diverse types of plastic waste without the need for multiple shredding machines.

In addition, the integration of advanced safety features in plastic shredder machines has significantly improved the overall safety standards in the industry. These safety features include emergency stop buttons, safety guards, and automatic shut-off mechanisms, which help prevent accidents and ensure the well-being of workers operating the machines.

Moreover, the latest advances in plastic shredder machine technology have focused on enhancing the overall environmental impact of the recycling process. Newer shredders are designed to minimize dust and noise pollution, making them more environmentally friendly and suitable for use in urban areas. Additionally, some machines are equipped with built-in filtration systems to capture and contain any harmful emissions, further reducing the environmental footprint of the recycling process.

Overall, the latest advances in plastic shredder machine technology have greatly improved the efficiency, versatility, and sustainability of plastic waste recycling. These machines have become essential tools for recycling facilities and waste management companies, helping them to meet the growing demand for sustainable waste management solutions. With ongoing research and development, it is likely that the future will bring even more advanced and innovative features to plastic shredder machines, further improving their effectiveness and environmental impact.

Impact of Latest Technological Advances

The Impact of Latest Technological Advances in Plastic Shredder Machine Technology

Plastic waste has become a major environmental concern in recent years, and the need for efficient plastic recycling has never been more urgent. This is where plastic shredder machines come into play, as they are a key technology in the process of breaking down and recycling plastic materials. In this article, we will explore the latest advances in plastic shredder machine technology and the impact they have had on the industry.

One of the most significant advancements in plastic shredder machine technology is the development of high-speed and high-capacity machines. These new machines are capable of processing large volumes of plastic waste in a fraction of the time it would take with older models. This increased efficiency has led to a significant reduction in the time and resources required for plastic recycling, making the process more cost-effective and sustainable.

Another important technological advance in plastic shredder machines is the integration of smart technology and automation. Modern machines are equipped with advanced sensors and monitoring systems that allow for precise control over the shredding process. This not only ensures consistent and high-quality output, but also minimizes the risk of machine malfunctions and downtime. Additionally, automation allows for greater flexibility in the operation of the machine, as it can be easily programmed to handle different types of plastic materials.

Furthermore, the latest advances in plastic shredder machine technology have led to improvements in the overall safety and environmental impact of the machines. New safety features, such as emergency stop buttons and automatic overload protection, help to prevent accidents and ensure the well-being of operators. Additionally, the introduction of energy-efficient motors and systems has reduced the machines' energy consumption and carbon footprint, making them more environmentally friendly.

In addition to these technological advancements, the latest plastic shredder machines also boast improved shredding capabilities. New cutting technologies and blade designs have enhanced the machines' ability to shred a wider range of plastic materials, including tougher and thicker items. This increased versatility has made it possible to process a greater variety of plastic waste, further contributing to the overall efficiency and effectiveness of the recycling process.

The impact of these advancements in plastic shredder machine technology cannot be overstated. The increased speed and capacity of the machines have allowed for a significant increase in the volume of plastic waste that can be recycled, leading to a reduction in the amount of plastic ending up in landfills or the ocean. Moreover, the improved efficiency and safety features have made the recycling process more sustainable and attractive to businesses and organizations looking to minimize their environmental impact.

In conclusion, the latest technological advances in plastic shredder machine technology have had a profound impact on the plastic recycling industry. These advancements have led to more efficient, versatile, and environmentally friendly machines that are changing the way we process and recycle plastic waste. As technology continues to evolve, we can expect further innovations that will further improve the sustainability and effectiveness of plastic shredder machines.

Improved Efficiency and Performance

Plastic shredder machine technology has seen significant advances in recent years, leading to improved efficiency and performance. These advancements have been driven by the increasing demand for more sustainable and cost-effective plastic waste management solutions. As the global plastic crisis continues to worsen, the need for better and more efficient plastic shredder machines has become increasingly pressing. In this article, we will explore the latest advances in plastic shredder machine technology and how these innovations are helping to address the challenges of plastic waste management.

One of the key areas of advancement in plastic shredder machine technology is in the design and construction of the machines themselves. Manufacturers have been focusing on creating machines that are more durable and capable of handling larger volumes of plastic waste. This has led to the development of shredder machines with more robust cutting blades and sturdier materials, allowing them to efficiently process a wider range of plastic materials. Additionally, advancements in machine design have also led to improved safety features and easier maintenance, making the operation of these machines more efficient and user-friendly.

Another area of advancement in plastic shredder machine technology is in the integration of smart technology and automation. Modern shredder machines are now equipped with advanced sensors and control systems that allow them to optimize their performance based on the type and volume of plastic waste being processed. These smart features not only improve the efficiency of the machines but also reduce the risk of errors and malfunctions, leading to more consistent and reliable shredding processes. Furthermore, the integration of automation technology allows for greater flexibility in the operation of the machines, enabling them to adapt to different shredding requirements with minimal manual intervention.

In addition to the technological advancements in machine design and automation, there have also been significant developments in the shredding process itself. New cutting techniques and shredding methodologies have been developed to improve the overall efficiency and performance of plastic shredder machines. These advancements have led to the development of machines that are capable of achieving higher throughput rates with reduced energy consumption, making them more cost-effective and environmentally friendly. Furthermore, these innovations have also resulted in a significant reduction in the generation of plastic waste residues, as the shredding process has become more efficient and precise.

The latest advances in plastic shredder machine technology have also been driven by the growing emphasis on sustainability and environmental responsibility. Manufacturers and operators of these machines are now increasingly focused on developing and implementing solutions that minimize the environmental impact of plastic waste management. This has led to the integration of technologies such as energy-efficient motors, advanced filtration systems, and noise-reducing components into the design of shredder machines, making them more sustainable and environmentally friendly.

In conclusion, the latest advances in plastic shredder machine technology have resulted in significant improvements in efficiency and performance. These advancements have been driven by the increasing demand for more sustainable and cost-effective plastic waste management solutions, leading to the development of machines that are more durable, efficient, and environmentally friendly. As the global plastic crisis continues to escalate, the ongoing innovation and development in plastic shredder machine technology will be crucial in addressing the challenges of plastic waste management and moving towards a more sustainable future.

Environmental Benefits and Sustainability

Plastic pollution is a global issue that has garnered increasing attention in recent years. As the amount of plastic waste continues to rise, so does the urgency to find sustainable solutions to manage and reduce this waste. One of the latest advances in technology that aims to tackle this problem is the plastic shredder machine. This article will explore the environmental benefits and sustainability of these machines, as well as the latest advances in their technology.

Plastic shredder machines play a crucial role in the recycling process by breaking down plastic waste into smaller pieces, making it easier to process and reuse. This, in turn, helps to reduce the amount of plastic that ends up in landfills and oceans, thereby minimizing the harmful impact of plastic pollution on the environment. By using a plastic shredder machine, recyclers can effectively transform plastic waste into valuable raw material, contributing to the circular economy and reducing the need for new plastic production.

In addition to their role in waste reduction, plastic shredder machines also offer sustainability benefits. These machines are designed to be energy-efficient and have low operating costs, making them a cost-effective and environmentally friendly solution for plastic recycling facilities. Furthermore, the use of recycled plastic materials in the manufacturing process can help to reduce carbon emissions and lessen the demand for virgin plastics, which are derived from fossil fuels. This, in turn, contributes to the overall sustainability and eco-friendliness of the plastic shredding process.

The latest advances in plastic shredder machine technology have further enhanced their environmental benefits and sustainability. One notable advancement is the development of high-performance shredders that are capable of processing a wider range of plastic materials, including thicker and tougher plastics. This means that a greater variety of plastic waste can be effectively recycled, leading to higher overall recycling rates and further reducing the environmental impact of plastic pollution.

Furthermore, advancements in shredder design have led to increased shredding efficiency and reduced energy consumption, making the process even more sustainable. Improved safety features and noise reduction technologies have also been incorporated into the latest models, addressing environmental and operational concerns. These developments not only contribute to the environmental benefits of plastic shredder machines but also improve overall operational performance and user experience.

In conclusion, plastic shredder machines offer a range of environmental benefits and contribute to overall sustainability efforts. The latest advances in their technology have further enhanced their ability to effectively process plastic waste, reduce environmental impact, and promote the circular economy. As the global community continues to prioritize sustainable waste management and plastic pollution reduction, the development and adoption of advanced plastic shredder machines will play a crucial role in achieving these goals.

Future Possibilities and Innovations in Plastic Shredding Technology

Plastic waste has become a major environmental concern in recent years, leading to an increased focus on developing more advanced plastic shredder machine technology to effectively and efficiently process and recycle plastic materials. In this article, we will explore the latest advances in plastic shredder machine technology and the future possibilities and innovations in this field.

One of the most significant innovations in plastic shredder machine technology is the development of high-speed shredders. These shredders are designed to quickly and efficiently shred large quantities of plastic waste, reducing the time and energy required for the shredding process. This is particularly important as the demand for recycled plastic continues to grow, and manufacturers are under pressure to process larger volumes of plastic waste.

Another area of innovation in plastic shredder machine technology is the integration of advanced automation and artificial intelligence (AI) technologies. These technologies enable shredder machines to operate more autonomously and make real-time adjustments to optimize shredding performance. For example, AI algorithms can analyze the composition of the plastic waste being shredded and adjust the shredding parameters to ensure a more consistent and uniform output.

In addition, there have been significant advancements in the design and construction of shredder blades and cutting systems. New materials and coatings have been developed to increase the durability and longevity of shredder blades, allowing them to maintain their sharpness and cutting efficiency over a longer period of time. This not only improves the overall performance of the shredder machine but also reduces the frequency of maintenance and blade replacement, leading to cost savings for operators.

Furthermore, the integration of sensor technology and data analytics has allowed for the development of smart shredder machines that can monitor and optimize their performance in real-time. Sensors are used to collect data on key operating parameters such as temperature, vibration, and energy consumption, which can then be analyzed to identify opportunities for improving efficiency and reducing downtime. This data-driven approach to shredder machine operation is becoming increasingly important as manufacturers seek to maximize the productivity and sustainability of their plastic recycling operations.

Looking towards the future, there are several exciting possibilities and innovations on the horizon for plastic shredder machine technology. One potential area of development is the use of advanced sorting and separation technologies to better process mixed plastic waste streams. By integrating advanced sorting technologies into shredder machines, it may be possible to more effectively separate different types of plastic materials, allowing for the creation of higher quality recycled plastic products.

Another area of future innovation is the development of more compact and mobile shredder machine designs. This could enable smaller recycling facilities and waste management operations to benefit from the capabilities of high-performance shredder technology, without the need for large and expensive equipment. Compact and mobile shredder machines could also be used for on-site shredding of plastic waste, reducing the need for transportation and handling of bulky plastic materials.

In conclusion, the latest advances in plastic shredder machine technology are paving the way for more efficient and sustainable plastic recycling processes. Through the integration of high-speed shredders, advanced automation and AI technologies, improved blade designs, and smart, data-driven operation, plastic shredder machines are becoming more capable and versatile than ever before. Looking ahead, the future possibilities and innovations in plastic shredder machine technology hold great promise for addressing the growing challenge of plastic waste and advancing the circular economy.

Conclusion

In conclusion, the latest advances in plastic shredder machine technology have revolutionized the way we recycle and process plastic waste. From improved shredding capabilities to enhanced safety features, these advancements have made plastic shredder machines more efficient, effective, and environmentally friendly. With the continued development and integration of cutting-edge technologies, we can expect even more innovative solutions to address the growing global issue of plastic pollution. As the demand for more sustainable waste management solutions increases, it is clear that the future of plastic shredder machines is bright, and we can look forward to a more sustainable and cleaner world.