It Is Efficient To Use A Plastic Shredder Machine In Production?

Are you looking to improve the efficiency of your production process? If so, then you need to consider the benefits of using a plastic shredder machine. In this article, we will discuss the advantages of incorporating a plastic shredder machine into your production line. From reducing waste to improving productivity, a plastic shredder machine can offer a wide range of benefits for your business. Read on to learn more about how this investment can make your production process more efficient and cost-effective.

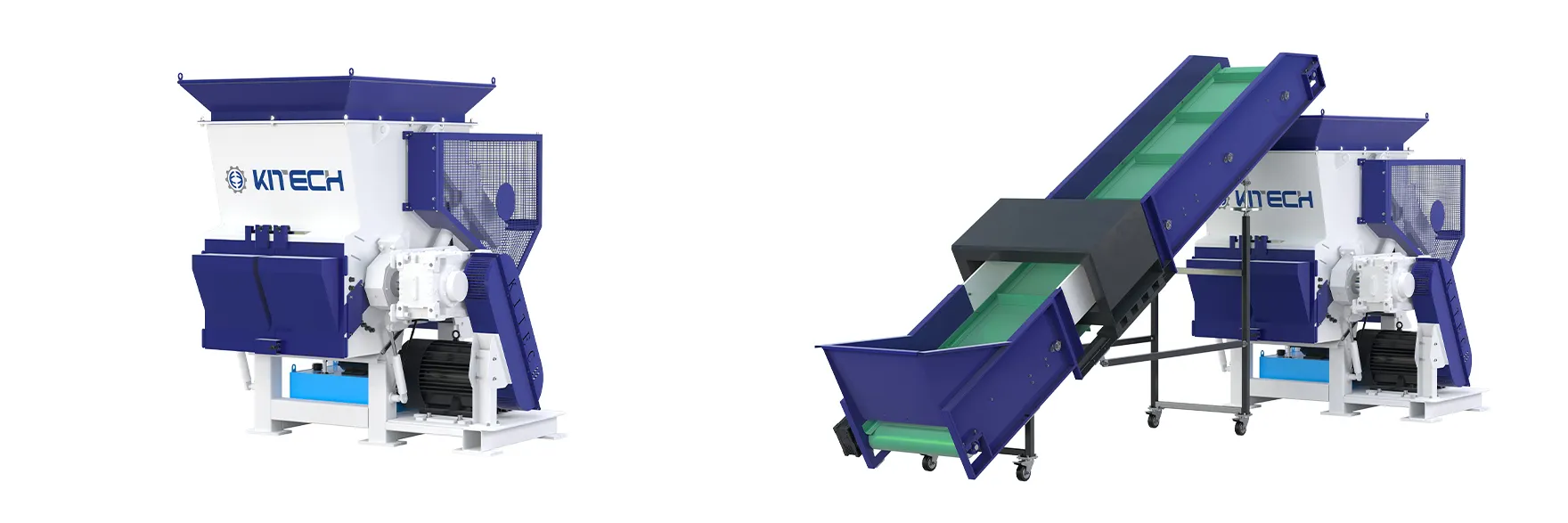

- Introduction to Plastic Shredder Machines

to Plastic Shredder Machines

Plastic shredder machines have become an essential tool in the manufacturing industry, aiding in the efficient processing of plastic waste. These machines are designed to break down plastic waste into smaller pieces, making it easier for recycling and disposal. In this article, we will explore the benefits of using a plastic shredder machine in production and how it contributes to the overall efficiency of the manufacturing process.

Plastic shredder machines are used to reduce the size of plastic waste by shredding it into smaller pieces. This process helps in reducing the volume of plastic waste, making it easier to transport and store. Additionally, shredding plastic waste also helps in preparing it for recycling, as smaller pieces are easier to process and re-use in the production of new plastic products.

One of the key benefits of using a plastic shredder machine in production is the reduction in waste and the associated costs. By shredding plastic waste, manufacturers can significantly reduce the amount of waste generated during the production process. This not only saves on disposal costs but also helps in minimizing the environmental impact of the manufacturing operations.

Furthermore, plastic shredder machines also contribute to the efficiency of the manufacturing process by enabling the re-use of plastic waste. Once shredded, the plastic waste can be processed and re-used in the production of new plastic products, thus reducing the reliance on raw materials. This not only helps in conserving natural resources but also reduces the overall production costs.

In addition to waste reduction and cost savings, plastic shredder machines also help in enhancing workplace safety. By shredding plastic waste on-site, manufacturers can minimize the risks associated with handling and transporting large volumes of plastic waste. This not only ensures a safer working environment for the employees but also reduces the potential for accidents and injuries.

Moreover, the use of plastic shredder machines in production also aligns with sustainable manufacturing practices. By efficiently managing plastic waste, manufacturers can demonstrate their commitment to environmental responsibility and sustainability. This, in turn, can enhance the company's reputation and appeal to environmentally conscious consumers.

In conclusion, the use of plastic shredder machines in production offers numerous benefits, ranging from waste reduction and cost savings to enhanced workplace safety and sustainability. By investing in these machines, manufacturers can not only streamline their production processes but also contribute to the responsible management of plastic waste. As the demand for sustainable manufacturing practices continues to grow, the use of plastic shredder machines is set to become an integral part of the manufacturing industry.

- The Benefits of Using a Plastic Shredder Machine in Production

In today's modern production processes, efficiency and sustainability are two key factors that manufacturers strive to achieve. In the plastic industry, the use of a plastic shredder machine has become increasingly popular due to its numerous benefits in production. From reducing waste to improving productivity, a plastic shredder machine offers a wide range of advantages for manufacturers. In this article, we will delve into the benefits of using a plastic shredder machine in production, and how it can revolutionize the way plastic materials are handled and processed.

One of the most significant benefits of using a plastic shredder machine in production is the reduction of waste. By shredding plastic materials into smaller, more manageable pieces, manufacturers can effectively minimize the amount of waste generated during the production process. This not only helps to cut down on disposal costs, but also contributes to a more sustainable and environmentally-friendly approach to production. Additionally, shredded plastic materials can often be recycled and reused, further reducing the environmental impact of plastic production.

Another key advantage of using a plastic shredder machine is the improvement in productivity. The shredding process allows for more efficient handling and processing of plastic materials, resulting in faster production times and increased output. This is particularly beneficial for manufacturers who deal with large volumes of plastic materials on a regular basis. With a plastic shredder machine, they can streamline their production processes and achieve higher levels of productivity without compromising on the quality of their products.

Furthermore, a plastic shredder machine also offers cost savings for manufacturers. By reducing waste and improving productivity, manufacturers can significantly lower their production costs and increase their overall profitability. Additionally, the ability to recycle shredded plastic materials can further contribute to cost savings, as it reduces the need for purchasing new raw materials. This makes a plastic shredder machine a valuable investment for manufacturers looking to improve their bottom line and stay competitive in the industry.

In addition to waste reduction, productivity improvement, and cost savings, a plastic shredder machine also provides a safer and more efficient working environment for production personnel. The shredding process eliminates the need for manual handling of large and bulky plastic materials, reducing the risk of accidents and injuries in the workplace. This not only ensures the safety and well-being of employees, but also enhances overall operational efficiency.

In conclusion, the benefits of using a plastic shredder machine in production are undeniable. From waste reduction to productivity improvement, cost savings, and a safer working environment, a shredder machine offers a wide range of advantages for manufacturers in the plastic industry. As the demand for sustainable and efficient production processes continues to grow, the use of a plastic shredder machine is becoming an essential tool for manufacturers looking to stay ahead in the market. By investing in a plastic shredder machine, manufacturers can not only enhance their production processes but also contribute to a more sustainable and environmentally-friendly approach to plastic production.

- How Plastic Shredder Machines Improve Efficiency in Production

In today’s fast-paced industrial world, efficiency is key in maintaining a competitive edge. One of the essential tools for improving efficiency in production is the plastic shredder machine. These machines are a critical component in the recycling and manufacturing industries for processing plastic waste and producing recycled plastic materials. Plastic shredder machines offer numerous benefits, including cost savings, resource conservation, and environmental sustainability. This article will explore how plastic shredder machines improve efficiency in production and the various advantages they offer to businesses.

First and foremost, plastic shredder machines are designed to efficiently process large volumes of plastic waste. By shredding plastic materials into smaller pieces, these machines make it easier to handle and transport the material for further processing. This saves valuable time and manpower, as the shredding process can be automated and integrated into existing production lines. Furthermore, the shredded plastic can be used as raw material for various manufacturing processes, reducing the need for new plastic production and ultimately cutting down on production costs.

Another important aspect of plastic shredder machines is their contribution to resource conservation. By recycling and reusing plastic waste, these machines help to conserve natural resources such as oil, gas, and water, which are essential for the production of virgin plastic materials. This not only reduces the demand for raw materials but also minimizes the environmental impact of plastic production. Additionally, using recycled plastic materials helps businesses meet sustainability goals and comply with environmental regulations, which is increasingly important in today’s global market.

In addition to cost savings and resource conservation, plastic shredder machines also play a significant role in reducing the amount of plastic waste that ends up in landfills. The ability to process and recycle plastic waste on-site means that businesses can effectively manage their waste stream and minimize their environmental footprint. This is particularly important for industries that generate large quantities of plastic waste, such as packaging, consumer goods, and automotive manufacturing. By investing in a plastic shredder machine, businesses can significantly reduce their waste disposal costs and demonstrate a commitment to environmental stewardship.

Furthermore, the use of plastic shredder machines can also improve workplace safety and efficiency by reducing the risk of accidents and injuries associated with manual handling of plastic waste. These machines are equipped with safety features and controls to prevent operator injuries and ensure smooth operation. By automating the shredding process, businesses can streamline their production workflow and optimize their overall efficiency. This not only benefits the bottom line but also creates a safer and more productive work environment for employees.

In conclusion, plastic shredder machines are an indispensable tool for improving efficiency in production. They offer a wide range of benefits, including cost savings, resource conservation, waste reduction, and workplace safety. By investing in a plastic shredder machine, businesses can enhance their production processes, reduce their environmental impact, and contribute to a more sustainable future. As the demand for recycled plastic materials continues to grow, plastic shredder machines will play a crucial role in shaping the future of the recycling and manufacturing industries.

- Factors to Consider When Implementing a Plastic Shredder Machine in Production

The use of plastic shredder machines in production has become increasingly popular in recent years. These machines offer a cost-effective and efficient way to recycle and process plastic materials for reuse in various industries. However, when considering implementing a plastic shredder machine in production, there are several important factors that must be taken into account. In this article, we will explore the key factors to consider when looking to integrate a plastic shredder machine into a production process.

One of the first factors to consider when implementing a plastic shredder machine in production is the type and volume of plastic materials that will be processed. Different shredder machines are designed to handle specific types of plastics, such as PET, HDPE, PVC, and more. It is important to choose a shredder machine that is capable of effectively shredding the specific types of plastic materials that will be used in the production process. Additionally, the volume of plastic materials that will be processed must also be taken into consideration when selecting a shredder machine, as this will determine the size and capacity of the machine that is needed.

Another important factor to consider is the size and layout of the production facility. The size of the production facility will determine the space available for the shredder machine, as well as the logistical considerations for integrating the machine into the production process. It is crucial to ensure that the shredder machine can be easily integrated into the existing production line without causing disruptions or inefficiencies. Additionally, the layout of the facility will impact the placement of the shredder machine and the workflow of the production process, so careful consideration must be given to these aspects.

Furthermore, the cost of implementing a plastic shredder machine in production must also be carefully evaluated. This includes not only the initial purchase cost of the machine but also the ongoing operational and maintenance costs. It is important to consider the potential return on investment that the shredder machine will provide, as well as the long-term cost savings that may be realized through more efficient plastic recycling and processing. Additionally, the availability of technical support and spare parts for the shredder machine should also be taken into account when assessing the overall cost of implementation.

Another important factor to consider when implementing a plastic shredder machine in production is the environmental impact of the machine. Plastic shredder machines play a crucial role in promoting sustainability and reducing the environmental impact of plastic waste. It is important to choose a shredder machine that is designed to minimize energy consumption and emissions, as well as to maximize the recycling and reuse of plastic materials. Additionally, the disposal of shredded plastic waste must also be taken into consideration to ensure that it is done in an environmentally responsible manner.

In conclusion, there are several key factors to consider when implementing a plastic shredder machine in production. By carefully evaluating the type and volume of plastic materials, the size and layout of the production facility, the cost of implementation, and the environmental impact of the machine, businesses can make informed decisions about integrating a shredder machine into their production processes. Ultimately, the efficient use of a plastic shredder machine in production can provide numerous benefits, including cost savings, environmental sustainability, and improved recycling capabilities.

- Conclusion: The Role of Plastic Shredder Machines in Streamlining Production Processes

Plastic shredder machines have revolutionized the production processes in various industries by streamlining operations and enhancing efficiency. In this article, we will explore the significant role that plastic shredder machines play in production processes and how they contribute to optimizing operations and reducing costs.

To begin with, plastic shredder machines are designed to efficiently shred plastic waste into smaller pieces, making it easier to recycle and reuse. This process not only helps in waste management but also contributes to environmental sustainability by reducing plastic pollution. Additionally, the shredded plastic can be used as raw material for manufacturing new products, thereby reducing the need for virgin plastic and lowering the carbon footprint.

One of the key benefits of using a plastic shredder machine in production is its ability to optimize material handling and processing. By breaking down large plastic items into smaller pieces, shredder machines facilitate easier transportation and storage of the material. This, in turn, leads to a more organized and efficient production floor, as the small shredded pieces can be easily fed into other processing equipment without the need for additional manual labor.

Furthermore, plastic shredder machines also play a crucial role in improving production efficiency and reducing downtime. With the ability to continuously shred plastic waste, these machines ensure a steady supply of raw material for production processes, eliminating the need for frequent halts and manual intervention. This results in a more streamlined and continuous production flow, ultimately leading to increased output and reduced production costs.

Moreover, the use of plastic shredder machines in production can significantly contribute to cost savings for businesses. By recycling and reusing shredded plastic, companies can reduce their reliance on expensive raw materials, thus lowering their production costs. Additionally, the efficient processing of plastic waste by shredder machines can also lead to savings in waste disposal and transportation costs, further adding to the overall cost-effectiveness of production operations.

Another important aspect to consider is the impact of plastic shredder machines on the quality of the final products. By ensuring a consistent and uniform size of shredded plastic, these machines contribute to the production of high-quality products with enhanced structural integrity. This, in turn, can lead to improved customer satisfaction and a better reputation for the company in the market.

In conclusion, plastic shredder machines play a vital role in streamlining production processes by facilitating efficient material handling, optimizing production flow, reducing downtime, and enhancing cost-effectiveness. As industries continue to prioritize sustainability and efficiency in their operations, the use of plastic shredder machines is expected to become increasingly prevalent in manufacturing and production settings. By investing in these machines, businesses can not only contribute to environmental conservation but also reap significant benefits in terms of operational efficiency and cost savings.

Conclusion

In conclusion, it is clear that using a plastic shredder machine in production can greatly improve efficiency and sustainability. By breaking down plastic waste into smaller, more manageable pieces, these machines make it easier to recycle and reuse materials, reducing the need for new plastic production. Additionally, the use of a plastic shredder machine can also save time and money by streamlining the waste management process. Overall, the benefits of using a plastic shredder machine in production are undeniable, and it is an efficient and practical solution for businesses looking to reduce their environmental impact and improve their bottom line. Investing in a plastic shredder machine is a smart decision for any company looking to make their production process more sustainable and efficient.