How To Select The Right Plastic Shredder Machine For Your Facility

Are you looking to streamline your facility's plastic recycling process? Choosing the right plastic shredder machine is a crucial decision that can significantly impact the efficiency and effectiveness of your operations. In this article, we will guide you through the important factors to consider when selecting a plastic shredder machine for your facility. From capacity and speed to maintenance and cost, we will provide you with the essential information you need to make an informed decision. Read on to ensure that you choose the right plastic shredder machine to meet your facility's specific needs and requirements.

Understanding Your Facility's Shredding Needs

When it comes to selecting the right plastic shredder machine for your facility, it's essential to first understand your facility's specific shredding needs. By evaluating the type and volume of plastic waste generated, the size of your facility, and the desired level of shredding, you can make an informed decision that aligns with your operational requirements and environmental sustainability goals.

Type and Volume of Plastic Waste

The first consideration in understanding your facility's shredding needs is identifying the type and volume of plastic waste generated. Different types of plastic materials require different shredding techniques and equipment. For example, while some plastic materials may be relatively easy to shred, others, such as hard plastics or mixed materials, may require a more robust shredder.

Additionally, the volume of plastic waste generated will also dictate the capacity and throughput requirements of the shredder machine. Facilities producing large volumes of plastic waste may require a high-capacity shredder with a powerful motor and durable cutting blades to efficiently process the material.

Size of Your Facility

The physical size and layout of your facility also play a critical role in determining the right plastic shredder machine. For smaller facilities with limited space, a compact and mobile shredder may be more practical, allowing for easy maneuverability and integration into existing workflows. On the other hand, larger facilities may benefit from a stationary shredder with a larger footprint and enhanced shredding capabilities to handle greater volumes of plastic waste.

Furthermore, the location of the shredder within the facility should be considered to optimize workflow and minimize transportation of plastic waste. Placing the shredder in close proximity to the source of plastic waste can streamline the disposal process and reduce operational downtime.

Desired Level of Shredding

The desired level of shredding is another important factor to consider when selecting a plastic shredder machine for your facility. Different applications may require varying degrees of shredding, ranging from coarse shredding for volume reduction to fine shredding for material size reduction and processing.

Furthermore, the end use of the shredded plastic material should also be taken into account. For recycling purposes, the shredded material may need to meet specific size and quality standards, necessitating a shredder with precision shredding capabilities.

In summary, understanding your facility's shredding needs is crucial in selecting the right plastic shredder machine. By evaluating the type and volume of plastic waste, the size of your facility, and the desired level of shredding, you can identify the most suitable shredder that aligns with your operational requirements and sustainability goals. Ultimately, investing in the right shredder machine will not only enhance your facility's waste management capabilities but also contribute to a more sustainable and efficient operation.

Comparing Different Types of Plastic Shredder Machines

When it comes to selecting the right plastic shredder machine for your facility, it's important to consider the different types available on the market. Each type of machine has its own unique features and benefits, and choosing the right one can have a significant impact on the efficiency and effectiveness of your plastic recycling or manufacturing operation.

One of the most common types of plastic shredder machines is the single shaft shredder. This type of machine is designed to handle a wide range of plastic materials, from smaller plastic containers to larger plastic pipes and profiles. Single shaft shredders are known for their high throughput capacity and are often used in larger facilities where a high volume of plastic waste needs to be processed.

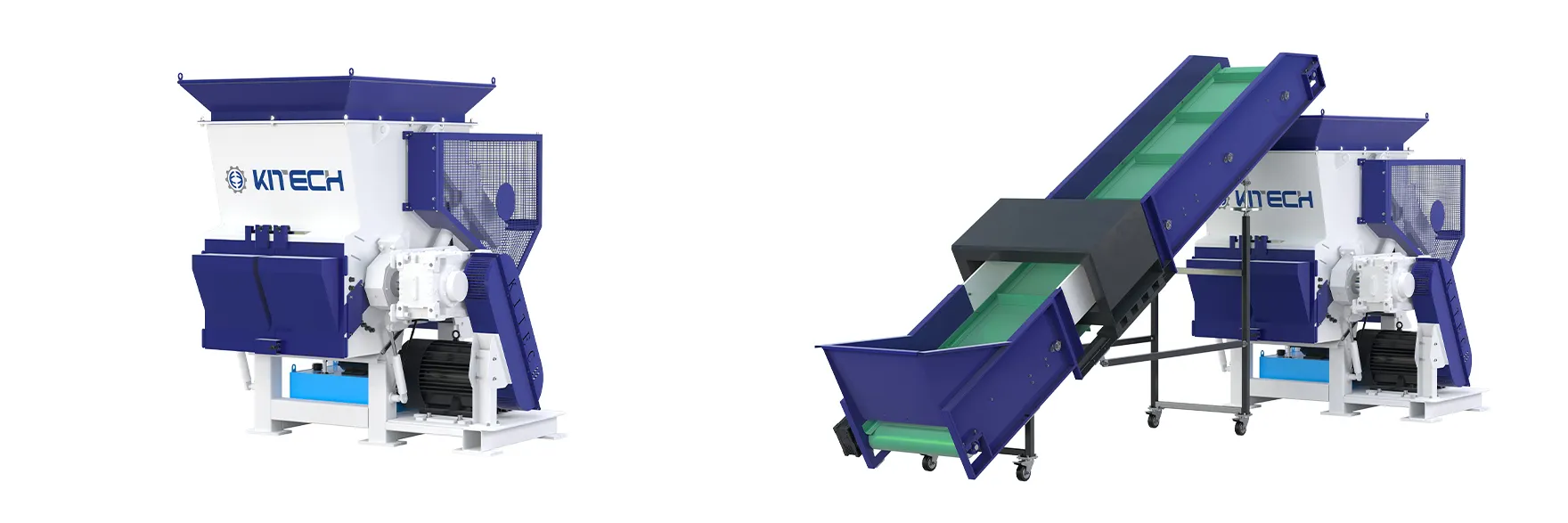

Another type of plastic shredder machine is the dual shaft shredder. This type of machine is equipped with two counter-rotating shafts that work together to efficiently shred plastic materials. Dual shaft shredders are known for their high torque and low speed, which makes them ideal for processing tough and bulky plastic items such as plastic drums, pallets, and packaging materials.

In addition to single and dual shaft shredders, there are also specialized plastic shredder machines designed for specific types of plastic materials. For example, there are shredders specifically designed for shredding plastic film and sheet, as well as machines designed for shredding plastic bottles and containers. These specialized machines are often equipped with features such as conveyor belts and size reduction screens to efficiently process and separate different types of plastic materials.

When selecting a plastic shredder machine for your facility, it's important to consider the specific requirements of your operation. Factors such as the volume and type of plastic waste you need to process, as well as the desired output size and quality of the shredded material, should all be taken into account. Additionally, factors such as the amount of space available in your facility, the power and energy requirements of the machine, and the maintenance and operational costs should also be considered.

Ultimately, selecting the right plastic shredder machine for your facility is crucial for maximizing the efficiency and effectiveness of your plastic recycling or manufacturing operation. By comparing the different types of machines available on the market and considering the specific requirements of your operation, you can make an informed decision that will help you achieve your recycling and manufacturing goals. Whether you choose a single shaft shredder, a dual shaft shredder, or a specialized shredder for specific types of plastic materials, investing in the right machine can have a significant impact on the success of your operation.

Evaluating the Capacity and Power Requirements

Plastic recycling has become a vital component of many industries, and the need for efficient and effective plastic shredder machines has never been more apparent. With the increasing demand for sustainable practices and waste reduction, selecting the right plastic shredder machine for your facility is paramount. One of the key aspects to consider when evaluating the capacity and power requirements of a plastic shredder machine is the type and volume of plastic waste your facility produces.

First and foremost, understanding the capacity of the plastic shredder machine is crucial. The capacity of a shredder is typically measured in pounds per hour (lb/hr) or kilograms per hour (kg/hr). It is essential to assess the volume of plastic waste your facility generates on a daily or weekly basis to determine the appropriate capacity of the shredder. If your facility produces a large volume of plastic waste, a high-capacity shredder would be necessary to efficiently process the material. Conversely, for smaller facilities with lower plastic waste output, a smaller capacity shredder would suffice.

In addition to capacity, the power requirements of a plastic shredder machine should also be taken into consideration. The power consumption of a shredder is typically measured in kilowatts (kW) or horsepower (HP). The power requirements of a shredder are directly related to its capacity and the type of plastic being processed. For instance, denser and tougher plastics may require a shredder with higher power output to effectively shred the material. It is important to assess the types of plastics your facility handles and the level of resistance they present to determine the appropriate power requirements for a shredder.

Furthermore, the size and design of the shredder machine should be evaluated in relation to the capacity and power requirements. The physical footprint of the shredder should align with the available space in your facility. Additionally, the design of the shredder, including features such as hopper size, cutting chamber dimensions, and motor configuration, should be tailored to the specific capacity and power needs of your facility. A well-designed shredder will enhance efficiency and productivity, while also minimizing energy consumption.

When evaluating the capacity and power requirements of a plastic shredder machine, it is imperative to also consider the potential for future growth and expansion. As your facility’s operations evolve, the volume and types of plastic waste may change. It is essential to select a shredder that can accommodate potential increases in capacity and power requirements in the future, without the need for frequent upgrades or replacements.

Ultimately, selecting the right plastic shredder machine for your facility involves a comprehensive assessment of the capacity and power requirements. Understanding the volume of plastic waste, the power consumption, and the potential for future growth are all integral to making an informed decision. By carefully evaluating these aspects, you can ensure that the shredder you choose is not only capable of meeting your current needs but also adaptable to the evolving demands of your facility.

Considering the Space and Installation Requirements

When looking to select the right plastic shredder machine for your facility, it is important to consider the space and installation requirements. A plastic shredder machine is a heavy-duty industrial equipment that requires ample space and specific installation considerations to ensure optimal performance and safety.

Space Requirements:

One of the first things to consider when selecting a plastic shredder machine is the space available in your facility. These machines come in a variety of sizes, from small-scale units to large industrial shredders. Before making a purchase, it is important to assess the available space and determine the dimensions required for the shredder. Consider factors such as clearance space around the machine for maintenance and operation, as well as access for loading and unloading materials.

Additionally, consider the layout of your facility and the flow of materials. The location of the shredder should be strategically placed to optimize workflow and efficiency. It is important to ensure that there is enough space to accommodate the shredder as well as the necessary auxiliary equipment, such as a conveyor belt or material feeding system.

Installation Requirements:

In addition to space considerations, it is crucial to take into account the installation requirements of the plastic shredder machine. These machines are heavy and require a stable foundation to operate effectively. Before installation, it is important to assess the flooring and infrastructure of your facility to ensure that it can support the weight and vibrations of the shredder.

Furthermore, electrical and utility requirements should be carefully considered. Industrial shredder machines typically require a significant amount of power to operate, and it is essential to have the appropriate electrical infrastructure in place to support the machine. Additionally, consider the availability of compressed air or other utilities that may be required for the operation of the shredder.

It is always recommended to work with a professional installation team to ensure that the shredder is properly set up and integrated into your facility. This will help to minimize the risk of issues such as vibrations, noise, or safety hazards that can arise from improper installation.

In conclusion, when selecting a plastic shredder machine for your facility, it is important to carefully consider the space and installation requirements. Assess the available space in your facility and determine the appropriate size and layout for the shredder. Additionally, take into account the installation requirements, including the need for a stable foundation and the necessary utilities to support the machine.

By carefully considering these factors, you can ensure that the plastic shredder machine is seamlessly integrated into your facility, allowing for optimal performance and efficiency. Working with a professional installation team can help to ensure that the shredder is properly set up and ready to meet your facility's industrial shredding needs.

Ensuring Compatibility with Maintenance and Safety Standards

Selecting the right plastic shredder machine for your facility is crucial in ensuring compatibility with maintenance and safety standards. With the increasing emphasis on environmental sustainability and waste management, the demand for efficient plastic shredding solutions has grown significantly. However, it is essential to consider various factors to choose the most suitable machine for your specific requirements.

First and foremost, it is essential to assess the type and volume of plastic waste that needs to be shredded. Different plastic shredder machines are designed to handle specific types of plastics, such as PET, PVC, HDPE, or mixed plastics. Understanding the composition of the plastic waste will help in selecting a machine that can effectively process the materials without compromising efficiency.

In addition to the type of plastic waste, the volume of material to be shredded is another critical factor to consider. Facilities generating large quantities of plastic waste will require a high-capacity shredder that can handle continuous operation without frequent maintenance or downtime. On the other hand, smaller facilities may opt for a smaller shredder that meets their daily shredding needs.

When considering a plastic shredder machine, maintenance and safety must be top priorities. Ensuring that the machine is compatible with maintenance schedules and safety standards is essential for long-term performance and the well-being of operators. Look for shredder machines with easy access to key components for routine maintenance and built-in safety features such as emergency stop buttons, safety interlocks, and overload protection.

Moreover, it is crucial to consider the power and cutting mechanism of the plastic shredder machine. The power requirements will depend on the volume and type of plastic waste to be shredded, as well as the desired output size. Some machines feature single shafts, while others may have dual or even quad shafts for enhanced cutting and shredding capabilities. Understanding the specific cutting requirements will help in selecting a machine that provides the desired output size and consistency.

Another important consideration is the integration of the plastic shredder machine into the existing facility layout. The machine should be compatible with the available space and layout for optimal operation and workflow. In addition, consider the noise level of the machine and its environmental impact, particularly if the facility operates in a residential or noise-sensitive area.

In conclusion, selecting the right plastic shredder machine for your facility involves a comprehensive assessment of the type and volume of plastic waste, maintenance and safety requirements, power and cutting mechanisms, and integration into the facility layout. By considering these factors, facilities can ensure compatibility with maintenance and safety standards while achieving efficient and effective plastic waste shredding. Ultimately, investing in the right plastic shredder machine will contribute to sustainable waste management practices and environmental responsibility.

Conclusion

In conclusion, selecting the right plastic shredder machine for your facility is a crucial decision that requires careful consideration of various factors such as the type and volume of plastic waste, available space, budget, and specific processing requirements. By following the guidelines provided in this article, you can make an informed decision and invest in a shredder machine that meets your facility's needs and provides efficient and reliable plastic waste management. Investing in the right shredder machine will not only improve the efficiency of your facility's waste management process but also contribute to environmental sustainability. So, take the time to evaluate your options and choose a plastic shredder machine that will benefit your facility for years to come.