How Do Plastic Shredder Machines Aid In Material Reduction?

Welcome to our article on the fascinating world of plastic shredder machines and how they play a crucial role in material reduction. As the demand for plastic products continues to rise, so does the need for efficient waste management solutions. In this article, we will explore the various ways in which plastic shredder machines aid in the reduction of materials, from recycling to waste management. Join us as we delve into the inner workings of these powerful machines and their impact on the environment. Whether you are a business owner, environmentalist, or simply curious about the latest advancements in waste reduction, this article is sure to pique your interest.

Understanding the Purpose of Plastic Shredder Machines

Plastic shredder machines play a crucial role in the recycling and waste management industry by reducing the volume of plastic waste and transforming it into valuable raw materials for manufacturing. Understanding the purpose of plastic shredder machines is essential for optimizing their usage and maximizing their benefits. In this article, we will delve into the functions, applications, and environmental impacts of plastic shredder machines to gain a comprehensive understanding of their role in material reduction.

Plastic shredder machines are designed to break down plastic waste into smaller, more manageable pieces, which are easier to handle, store, and transport. These machines utilize powerful rotating blades to shred various types of plastic materials, including bottles, containers, packaging, and other plastic products. The shredded plastic can then be further processed into granules or pellets, which can be used as raw materials for producing new plastic products or other industrial applications.

One of the key purposes of plastic shredder machines is to reduce the volume of plastic waste, which in turn helps to minimize the burden on landfills and the environment. By shredding plastic waste into smaller pieces, these machines enable efficient storage and transportation of the material, leading to reduced space requirements and lower transportation costs. Additionally, the shredded plastic can be easily recycled and reused, reducing the need for virgin plastic production and the associated environmental impacts.

Plastic shredder machines also play a vital role in the circular economy, where materials are continuously recycled and reused to reduce waste and minimize resource consumption. By transforming plastic waste into reusable raw materials, these machines contribute to the sustainability of the plastic industry and help mitigate the environmental effects of plastic pollution. Furthermore, the use of recycled plastic materials in manufacturing helps to conserve natural resources and reduce carbon emissions associated with plastic production.

In addition to waste reduction and recycling, plastic shredder machines are also instrumental in the destruction of confidential or sensitive materials. Many industries, such as healthcare, finance, and government, require the secure disposal of documents, products, or packaging containing sensitive information. By using a plastic shredder machine, these materials can be effectively destroyed, ensuring the confidentiality and security of the information while preventing unauthorized access or misuse.

Furthermore, plastic shredder machines can be utilized in the production of alternative fuels, such as solid recovered fuel (SRF) or refuse-derived fuel (RDF). Through the shredding and processing of non-recyclable plastic materials, these machines can generate fuel sources that can be used in industrial processes, power generation, or heating applications. This innovative approach to waste-to-energy conversion contributes to the reduction of fossil fuel consumption and the promotion of renewable energy resources.

In conclusion, plastic shredder machines play a multifaceted role in material reduction, waste management, and resource conservation. By understanding the purpose and applications of these machines, we can harness their potential to drive sustainable practices and contribute to a more circular and environmentally responsible plastic industry. As the demand for plastic waste management and recycling continues to grow, the importance of plastic shredder machines in material reduction cannot be overstated.

Advantages of Using Plastic Shredder Machines for Material Reduction

Plastic shredder machines have become an integral part of the recycling and material reduction process in various industries. These powerful machines are designed to break down plastic waste into smaller, more manageable pieces, which can then be further processed and recycled into new products. In this article, we will explore the numerous advantages of using plastic shredder machines for material reduction.

One of the primary benefits of using plastic shredder machines is their ability to significantly reduce the volume of plastic waste. By shredding plastic materials into smaller pieces, these machines make it easier to store, transport, and process the waste. This can result in cost savings for businesses, as they can reduce the frequency of waste pickups and save on storage space.

In addition to reducing the volume of plastic waste, shredder machines also help to improve the efficiency of recycling processes. The shredded plastic can be melted down and reshaped into new products, which helps to conserve natural resources and reduce the need for virgin plastic materials. This not only benefits the environment but also helps businesses save money on raw materials.

Furthermore, plastic shredder machines play a crucial role in the destruction of sensitive or confidential materials. Many businesses and organizations use shredder machines to destroy documents, products, and other materials that contain sensitive information. The shredded plastic cannot be reassembled, ensuring that the information remains secure and confidential.

Another advantage of using plastic shredder machines is their versatility. These machines can process a wide range of plastic materials, including bottles, containers, packaging, and more. This flexibility makes them suitable for use in various industries, such as manufacturing, recycling, and waste management.

Moreover, plastic shredder machines are designed with safety in mind. They are equipped with safety features and mechanisms to prevent accidents and protect the operators. This ensures that the machines can be operated safely and effectively, minimizing the risk of injuries or damages.

In conclusion, plastic shredder machines offer a multitude of benefits for businesses and industries looking to reduce plastic waste and improve recycling processes. These machines help to minimize the volume of plastic waste, increase the efficiency of recycling, secure sensitive materials, and offer versatility and safety. As the demand for sustainable and environmentally friendly practices continues to grow, the use of plastic shredder machines will undoubtedly play a crucial role in achieving these goals.

Types of Plastic Shredder Machines and Their Functionality

Plastic shredder machines are essential tools in the recycling and waste management industry. These machines are designed to reduce the size of plastic waste, making it easier to transport, recycle, and dispose of. There are several different types of plastic shredder machines, each with its unique functionality and benefits. In this article, we will explore the various types of plastic shredder machines and how they aid in material reduction.

The single shaft shredder is a versatile machine that is commonly used in the recycling industry. This type of shredder features a single rotating shaft with strategically placed blades that effectively shear and tear plastic waste into smaller pieces. The single shaft shredder is suitable for a wide range of plastic materials and can handle various sizes and shapes of plastic waste.

Dual Shaft Shredder:

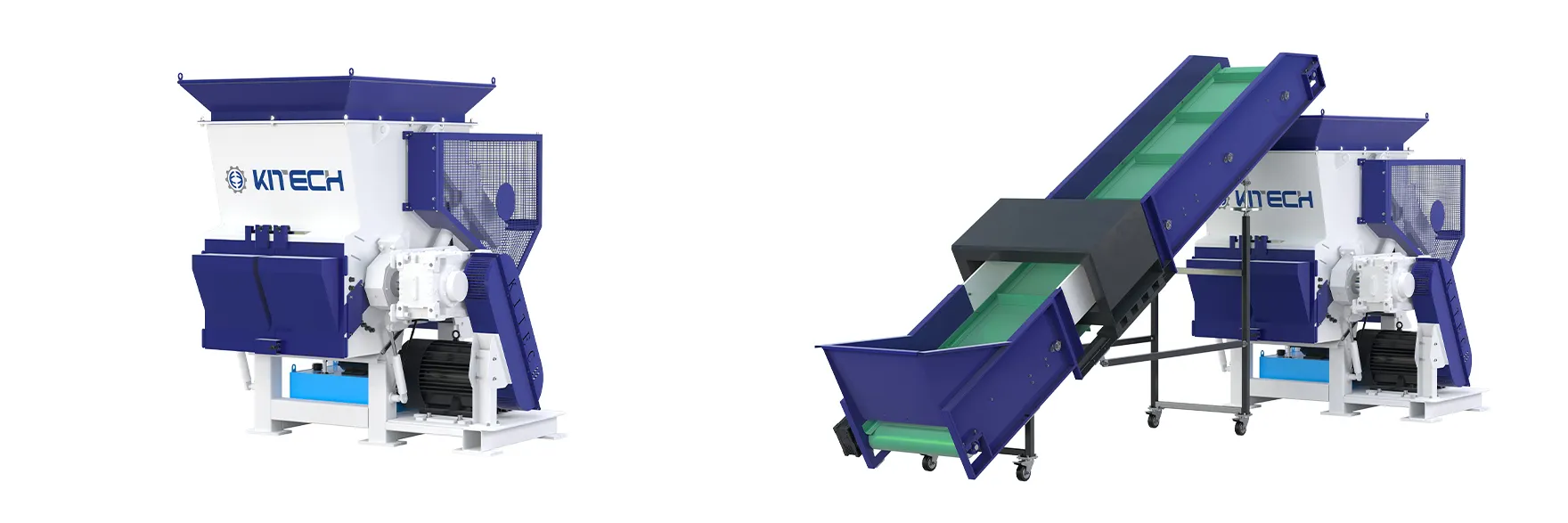

The dual shaft shredder is a more robust and heavy-duty machine that is ideal for processing large volumes of plastic waste. This type of shredder features two counter-rotating shafts with interlocking blades that efficiently shred and reduce plastic waste. The dual shaft shredder is capable of handling bulky and dense plastic materials, making it a reliable solution for industrial and commercial applications.

Granulators:

Granulators are another type of plastic shredder machine that is commonly used in the recycling industry. These machines utilize high-speed rotating knives to cut and reduce plastic waste into smaller granules. Granulators are particularly effective in processing plastic scrap, purgings, and other post-industrial waste.

Shredder-Granulator Combination Machines:

Some plastic shredder machines are designed to combine the functionality of a shredder and a granulator into a single unit. These machines offer the benefits of both shredding and granulating processes, making them highly efficient in reducing plastic waste. The shredder-granulator combination machines are versatile and can handle a wide range of plastic materials and applications.

Functionality of Plastic Shredder Machines:

Plastic shredder machines play a crucial role in material reduction by effectively breaking down plastic waste into smaller, more manageable pieces. By reducing the size of plastic waste, these machines make it easier to transport, store, and process the material for recycling or disposal. Additionally, plastic shredder machines help to improve the efficiency of recycling processes by preparing the plastic waste for further processing, such as melting and extrusion.

In conclusion, plastic shredder machines are essential tools in the recycling and waste management industry. There are several different types of plastic shredder machines, each with its unique functionality and benefits. From single shaft shredders to dual shaft shredders, granulators, and shredder-granulator combination machines, there is a wide range of options available to suit various applications and processing requirements. These machines play a vital role in material reduction and contribute to the sustainable management of plastic waste.

Environmental Impact of Using Plastic Shredder Machines

Plastic shredder machines have become an essential tool in the recycling industry, aiding in the reduction of materials and promoting sustainability. However, it is crucial to consider the environmental impact of using these machines, as they can both benefit and harm the environment. In this article, we will explore the environmental impact of using plastic shredder machines from different angles, including energy consumption, emissions, and waste reduction.

Energy Consumption

One of the most significant environmental impacts of plastic shredder machines is their energy consumption. These machines require a significant amount of electricity to operate, especially the larger industrial-sized shredders. The energy used in the production of the machines themselves, as well as their ongoing operational energy requirements, must be taken into account when assessing their overall environmental impact.

To mitigate this impact, it is essential to ensure that plastic shredder machines are designed to be energy-efficient. Utilizing modern technologies, such as energy-efficient motors and optimized shredding processes, can help reduce the energy consumption of these machines and lessen their environmental impact.

Emissions

In addition to energy consumption, the emissions produced by plastic shredder machines must also be considered. The operation of these machines can generate emissions such as carbon dioxide and other pollutants, contributing to air pollution and climate change. To address this, it is crucial to implement proper emissions control measures, such as the use of efficient filters and the adoption of cleaner technologies.

Waste Reduction

Despite the energy consumption and emissions associated with plastic shredder machines, their use ultimately contributes to waste reduction and environmental conservation. By shredding plastic waste into smaller pieces, these machines enable the recycling and reuse of materials that would otherwise end up in landfills or oceans. This, in turn, helps to conserve natural resources, reduce the need for virgin plastic production, and minimize the overall environmental impact of plastic consumption.

When evaluating the environmental impact of using plastic shredder machines, it is essential to consider the broader context of waste management and resource conservation. While these machines do consume energy and produce emissions, their role in reducing plastic waste and promoting sustainability cannot be overlooked. By implementing energy-efficient technologies and emissions control measures, the environmental impact of plastic shredder machines can be minimized while reaping the benefits of waste reduction and material conservation.

In conclusion, the environmental impact of using plastic shredder machines is multifaceted and requires careful consideration of factors such as energy consumption, emissions, and waste reduction. By prioritizing energy efficiency and emissions control, the negative environmental impact of these machines can be mitigated, while their positive role in material reduction and resource conservation is maximized. As the recycling industry continues to evolve, it is crucial to embrace technologies that balance environmental concerns with the necessity of waste reduction and sustainable material management.

Considerations for Choosing the Right Plastic Shredder Machine for Your Needs

Plastic shredder machines are an essential part of the recycling process, as they aid in the reduction of plastic materials into smaller, more manageable pieces. When choosing the right plastic shredder machine for your needs, there are several important considerations to keep in mind.

First and foremost, it is important to consider the type of plastic materials that will be shredded. Different types of plastic have different properties, and some may require a more heavy-duty shredder to effectively reduce them to the desired size. For example, soft plastics such as polyethylene and polypropylene may require a different type of shredder compared to harder plastics like PVC or PET. It is crucial to choose a shredder that is designed to handle the specific type of plastic materials that will be processed.

Another important consideration is the size and capacity of the plastic shredder machine. The size of the machine should be able to accommodate the volume of plastic materials that need to be shredded. A small-scale operation may only require a compact shredder, while larger industrial facilities will need a larger, more powerful machine. It is also important to consider the throughput capacity of the shredder, as this will determine how quickly and efficiently the materials can be processed.

In addition to size and capacity, it is important to consider the shredding mechanism of the machine. There are different types of shredders available, including single-shaft, double-shaft, and quad-shaft shredders. Each type of shredder has its own unique advantages and is suited for different types of materials and applications. For example, single-shaft shredders are ideal for processing plastic film and lightweight plastics, while double-shaft shredders are better suited for harder and thicker materials.

Furthermore, the maintenance and durability of the plastic shredder machine are important factors to consider. It is important to choose a machine that is built to last and can withstand the demands of continuous operation. Regular maintenance is also crucial to ensure the longevity and efficiency of the machine. Consider the availability of replacement parts and the level of technical support offered by the manufacturer when selecting a shredder.

Finally, it is important to consider the overall cost and return on investment of the plastic shredder machine. While it is tempting to opt for the cheapest option available, it is important to consider the long-term costs and benefits of the machine. A higher initial investment may be justified if it results in higher productivity, efficiency, and lower maintenance costs in the long run.

In conclusion, choosing the right plastic shredder machine for your needs requires careful consideration of the type of materials, size and capacity, shredding mechanism, maintenance and durability, and overall cost. By taking these factors into account, you can ensure that you select a shredder that is well-suited for your specific needs and will provide reliable and efficient material reduction for years to come.

Conclusion

In conclusion, plastic shredder machines play a crucial role in material reduction by efficiently breaking down plastic waste into smaller, more manageable pieces. This not only aids in reducing the volume of plastic waste that ends up in landfills but also facilitates the recycling process. Additionally, these machines help in minimizing the environmental impact of plastic pollution by creating opportunities for the reuse and repurposing of plastic materials. By investing in and utilizing plastic shredder machines, we can take a significant step towards promoting sustainability and reducing the negative effects of plastic waste on our planet. It is clear that these machines are invaluable in our efforts to combat plastic pollution and create a more sustainable future.