Does A Plastic Shredder Machine Lower Noise Pollution?

Are you looking for an efficient and environmentally friendly way to reduce noise pollution in your workplace or community? Look no further than the plastic shredder machine. In this article, we will explore the potential of a plastic shredder machine to lower noise pollution and its impact on the environment. Read on to discover how this innovative technology can make a positive difference in your surroundings.

- Understanding the Impact of Noise Pollution

Noise pollution is an often overlooked but serious environmental issue that affects millions of people worldwide. From the constant hum of traffic to the loud rattling of industrial machinery, noise pollution can have a major impact on our health and well-being. In recent years, there has been a growing awareness of the need to address this problem, and one potential solution that has emerged is the use of plastic shredder machines.

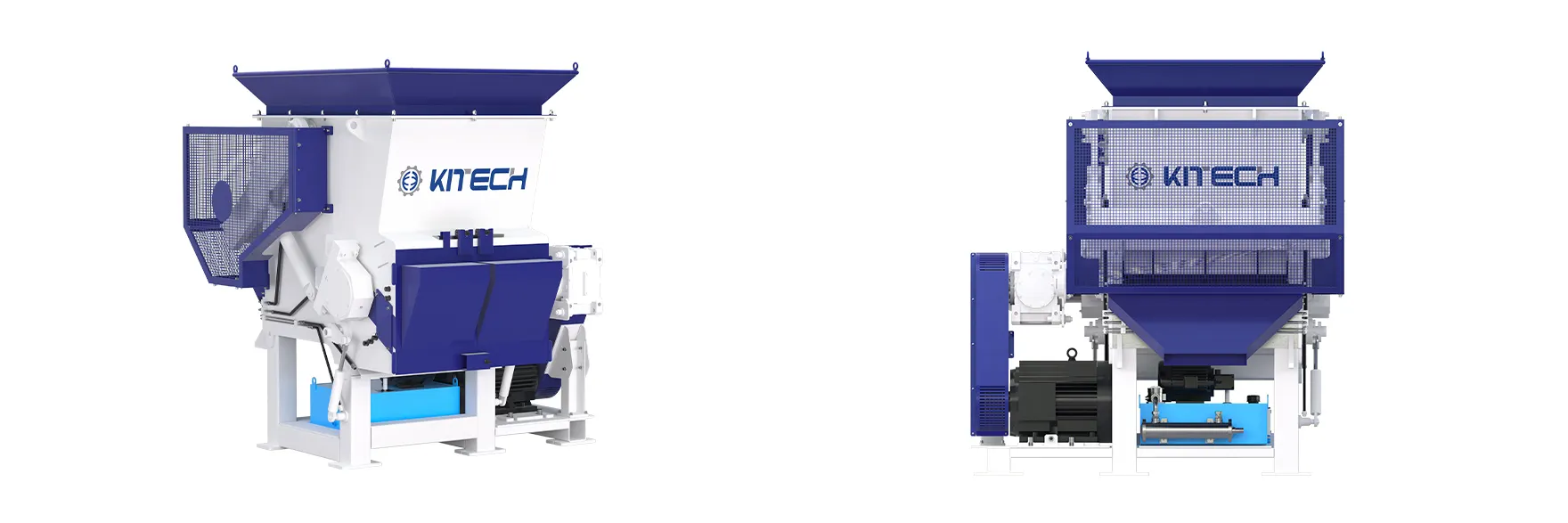

Plastic shredder machines are industrial equipment designed to shred and granulate plastic waste materials. These machines are commonly used in recycling facilities, manufacturing plants, and other industrial settings to process plastic waste into smaller, more manageable pieces. While the primary purpose of these machines is to facilitate the recycling process, they also have the potential to play a role in reducing noise pollution.

The impact of noise pollution on the environment and human health cannot be overstated. Chronic exposure to high levels of noise can lead to a wide range of health problems, including hearing loss, stress, sleep disturbances, and cardiovascular issues. In addition to these direct health effects, noise pollution can also have a negative impact on wildlife, disrupting natural habitats and affecting the behavior and communication of animals.

So how exactly can a plastic shredder machine help to lower noise pollution? The key lies in the design and operation of these machines. Modern plastic shredder machines are built with noise reduction features, such as sound insulation and vibration dampening technology. This helps to minimize the amount of noise generated during the shredding process, making these machines much quieter than traditional industrial equipment.

In addition to reducing noise pollution at the source, plastic shredder machines also contribute to overall environmental sustainability. By processing plastic waste into smaller pieces, these machines make it easier to transport and recycle the material, ultimately diverting it from landfills and incinerators. This not only helps to reduce the environmental impact of plastic pollution but also contributes to a quieter, cleaner environment.

Furthermore, the use of plastic shredder machines can also have a positive impact on local communities. By lowering noise pollution in industrial settings, these machines can help to improve the quality of life for nearby residents and workers. This is particularly important in densely populated urban areas, where noise pollution from industrial activities can be a significant concern.

While plastic shredder machines have the potential to lower noise pollution, it is important to note that their effectiveness can vary depending on various factors such as the specific model, maintenance, and the surrounding environment. Additionally, it is also crucial for manufacturers and operators to adhere to proper safety guidelines and regulations to ensure that these machines operate efficiently and with minimal impact on the environment.

In conclusion, plastic shredder machines have the potential to play a significant role in reducing noise pollution and promoting a more sustainable, environmentally-friendly approach to plastic waste management. By incorporating noise reduction features and facilitating the recycling process, these machines can help to create a quieter, cleaner environment for both humans and wildlife. As the global community continues to address the challenges of noise pollution, the use of innovative technologies such as plastic shredder machines will be an important part of the solution.

- Introducing Plastic Shredder Machines as a Solution

Plastic pollution has become a major environmental issue in the modern world, with millions of tons of plastic waste being generated each year. This waste creates a significant pollution problem, with plastic debris being found in oceans, rivers, and on land. As a result, there is a growing need for effective solutions to manage and reduce plastic pollution, and one potential solution is the use of plastic shredder machines.

Plastic shredder machines are designed to shred plastic waste into smaller pieces, which can then be recycled or disposed of more effectively. These machines come in a variety of sizes and configurations, and are capable of processing a wide range of plastic materials, including bottles, containers, and packaging. By reducing plastic waste into smaller pieces, these machines can have a significant impact on reducing the volume of plastic waste that ends up in landfills or in the environment.

One potential benefit of using plastic shredder machines is their ability to lower noise pollution. Traditional methods of plastic waste disposal, such as incineration or crushing, can generate significant levels of noise, which can be a major concern for workers and nearby residents. With the use of shredder machines, the noise levels can be significantly reduced, making the process of plastic waste management more environmentally friendly and socially acceptable.

Another important benefit of plastic shredder machines is their ability to increase the efficiency of plastic waste management. By shredding plastic waste into smaller pieces, these machines make it easier to transport and process the waste, ultimately saving time and resources. This increased efficiency not only lowers the overall impact of plastic waste on the environment, but also reduces the cost of managing and disposing of plastic waste.

Furthermore, the use of plastic shredder machines can also support the development of a circular economy for plastics. By shredding plastic waste into smaller pieces, these machines make it easier to recycle and reuse the material, ultimately reducing the need for new plastic production. This can help to mitigate the environmental impact of plastic production and consumption, and contribute to a more sustainable approach to managing plastic waste.

In conclusion, plastic shredder machines have the potential to significantly reduce noise pollution associated with plastic waste management, while also improving efficiency and supporting the development of a circular economy for plastics. With their ability to process a wide range of plastic materials and reduce them into smaller pieces, these machines offer an effective solution to managing the growing problem of plastic pollution. As the demand for sustainable solutions to plastic waste management continues to grow, the use of plastic shredder machines is likely to play an increasingly important role in addressing this global environmental challenge.

- Evaluating the Effectiveness of Plastic Shredder Machines

Plastic pollution has become a significant environmental issue, with plastic waste contaminating ecosystems and causing harm to wildlife. While efforts to reduce plastic usage and increase recycling have been implemented, the disposal of plastic waste remains a challenge. One method that has gained attention in recent years is the use of plastic shredder machines to break down plastic waste into more manageable pieces. This article evaluates the effectiveness of plastic shredder machines in reducing noise pollution and examines their potential impact on the environment.

Plastic shredder machines are designed to shred, crush, and grind plastic waste into smaller particles, making it easier to transport and recycle. These machines come in various sizes and configurations, ranging from small household units to large industrial shredders used by waste management facilities. One of the primary considerations in evaluating the effectiveness of plastic shredder machines is their ability to reduce the overall noise pollution generated during the shredding process.

Noise pollution is a significant concern in urban and industrial areas, with heavy machinery and industrial processes contributing to high levels of environmental noise. When it comes to plastic shredder machines, the noise generated during the shredding process can impact workers' health and safety, as well as the surrounding community. Therefore, it is essential to assess whether plastic shredder machines can lower noise pollution and provide a more sustainable solution for plastic waste management.

Several factors contribute to the noise generated by plastic shredder machines, including the type of machine, the material being shredded, and the operating conditions. For instance, while smaller household plastic shredders may produce relatively low levels of noise, industrial-scale shredders can generate high levels of sound, particularly when processing hard or dense plastics. In addition, the maintenance and proper operation of shredder machines can also affect their noise output.

To evaluate the effectiveness of plastic shredder machines in lowering noise pollution, it is necessary to conduct sound level measurements during the shredding process. These measurements can be used to compare the noise levels produced by different types of shredder machines and assess their impact on the surrounding environment. Additionally, studies comparing the noise emissions of plastic shredder machines to other waste management methods, such as incineration or landfill disposal, can provide valuable insights into their overall environmental impact.

In addition to their impact on noise pollution, plastic shredder machines also offer environmental benefits by facilitating the recycling and repurposing of plastic waste. By breaking down plastic materials into smaller pieces, shredder machines make it easier to process and recycle plastic, reducing the amount of plastic waste that ends up in landfills or the natural environment. This aspect of their effectiveness should also be considered when evaluating their overall contribution to sustainable waste management practices.

In conclusion, plastic shredder machines have the potential to lower noise pollution and provide a more sustainable solution for managing plastic waste. By evaluating their noise emissions and environmental impact, we can gain a better understanding of their effectiveness and identify ways to improve their efficiency and environmental performance. As the demand for effective plastic waste management solutions continues to grow, assessing the effectiveness of plastic shredder machines will be essential in addressing the challenges of plastic pollution and promoting a more sustainable future.

- Examining the Potential for Noise Reduction

In today’s industrialized society, the issue of noise pollution has become increasingly prevalent, with machinery and equipment being one of the primary contributors to this problem. As a result, there has been a growing interest in implementing solutions to mitigate the impact of noise pollution, particularly in the manufacturing and recycling sectors. One such solution that has gained attention is the use of plastic shredder machines and their potential for reducing noise pollution.

Plastic shredder machines are commonly used to break down plastic waste into smaller pieces for recycling purposes. These machines typically consist of a high-speed rotor with sharp blades that shred the plastic into smaller particles. While these machines play a critical role in the recycling process, they are also known for generating significant noise levels, which can contribute to noise pollution in the surrounding environment.

In recent years, there has been a concerted effort to examine the potential for noise reduction in plastic shredder machines. Manufacturers and researchers have been exploring various approaches to address this issue, aiming to develop more efficient and quieter machines for the industry.

One approach to reducing noise pollution from plastic shredder machines is through the use of advanced engineering and design principles. By optimizing the machine's components and structure, manufacturers can minimize vibration and resonance, which are common sources of noise in shredder machines. Additionally, the incorporation of noise-reducing materials and acoustic insulation can further dampen the sound produced during operation.

Another strategy for noise reduction involves the implementation of cutting-edge technology, such as noise-canceling systems and soundproofing techniques. These technologies can be integrated into the machine's design to actively mitigate noise emissions, providing a more conducive working environment for operators and minimizing the impact on the surrounding community.

Furthermore, advancements in motor and drive systems also offer opportunities for noise reduction in plastic shredder machines. By utilizing energy-efficient motors and drive technologies, manufacturers can achieve smoother and quieter operation, ultimately contributing to reduced noise pollution.

It is important to acknowledge that the potential for noise reduction in plastic shredder machines extends beyond the technical aspects. Proper maintenance and operational practices also play a critical role in minimizing noise emissions. Regular servicing and lubrication of machine components, as well as the implementation of sound management protocols, can significantly contribute to reducing noise levels during shredding operations.

In conclusion, the examination of the potential for noise reduction in plastic shredder machines is a multifaceted endeavor that encompasses technological innovation, engineering principles, and operational best practices. As the industry continues to prioritize environmental sustainability and community well-being, the development of quieter and more efficient shredder machines holds significant promise in addressing the issue of noise pollution. By leveraging a holistic approach that encompasses design, technology, and operational considerations, plastic shredder machines can play a pivotal role in fostering a quieter and more sustainable manufacturing and recycling landscape.

- Implementing Plastic Shredder Machines to Lower Noise Pollution

Plastic pollution has become a major environmental concern in recent years, prompting the need for effective waste management solutions. One of the key elements of this issue is the noise pollution caused by the process of shredding plastic waste. In an effort to address this problem, many industries and facilities have turned to implementing plastic shredder machines to lower noise pollution. But the question remains: does a plastic shredder machine effectively lower noise pollution?

To understand the impact of plastic shredder machines on noise pollution, it is important to first grasp the process of plastic shredding and its associated noise levels. Plastic shredder machines are designed to break down plastic waste into smaller pieces, making it easier to manage and recycle. However, the shredding process involves powerful motors and cutting blades that can produce high levels of noise. This noise not only affects workers in the vicinity but can also contribute to overall environmental noise pollution.

To mitigate the impact of noise pollution, manufacturers have developed advanced plastic shredder machines with noise reduction features. These machines are equipped with soundproofing materials, insulated chambers, and efficient motor technologies to minimize noise levels during operation. Additionally, some models incorporate automatic noise control systems that adjust the machine's settings to reduce noise output based on the type and quantity of plastic being shredded.

The implementation of these advanced plastic shredder machines has shown promising results in lowering noise pollution within industrial and recycling facilities. Studies have indicated a significant decrease in noise levels when using these specialized machines, creating a quieter and more conducive work environment. Furthermore, the reduced noise output benefits surrounding communities by minimizing the impact of industrial activities on the local noise environment.

In addition to noise reduction, plastic shredder machines offer other environmental benefits that contribute to overall pollution control. By effectively breaking down and recycling plastic waste, these machines help reduce the amount of plastic entering landfills and oceans, thereby mitigating the environmental impact of plastic pollution. This dual benefit of lowering noise pollution and addressing plastic waste management highlights the positive impact of implementing plastic shredder machines in various industries.

Furthermore, the adoption of plastic shredder machines aligns with global efforts to promote sustainable and eco-friendly practices. As the demand for plastic recycling and waste management solutions continues to grow, it is crucial for industries to invest in technologies that not only address the environmental impact of plastic waste but also minimize the associated noise pollution. The integration of noise-reducing plastic shredder machines exemplifies a proactive approach to sustainable waste management and environmental stewardship.

In conclusion, the implementation of plastic shredder machines has demonstrated a clear potential to lower noise pollution within industrial and recycling facilities. These advanced machines, equipped with noise reduction features, offer a practical solution to mitigate the environmental and occupational impact of noise generated during the plastic shredding process. As the need for sustainable waste management practices continues to increase, the use of plastic shredder machines is likely to play a pivotal role in reducing both plastic pollution and noise pollution, contributing to a healthier and more environmentally conscious future.

Conclusion

In conclusion, the use of a plastic shredder machine does indeed help to lower noise pollution. By efficiently breaking down plastic materials, these machines reduce the need for loud manual processes, thus decreasing overall noise levels in the environment. Additionally, modern shredder machines are designed with noise-reducing features, further contributing to a quieter and more sustainable working environment. With the growing concern over noise pollution and its negative impact on health and well-being, investing in plastic shredder machines is not only beneficial for waste management but also for creating a more peaceful and harmonious world for future generations. So, when it comes to reducing noise pollution, a plastic shredder machine is certainly a step in the right direction.