Does A Plastic Shredder Machine Increase Operational Safety?

Welcome to our discussion on the topic of plastic shredder machines and their impact on operational safety. In the age of environmental consciousness, plastic shredder machines have become increasingly popular for recycling and waste management. However, many are left wondering if these machines actually increase operational safety. Join us as we explore the question "Does a Plastic Shredder Machine Increase Operational Safety?" and delve into the potential benefits and risks associated with these powerful and essential tools.

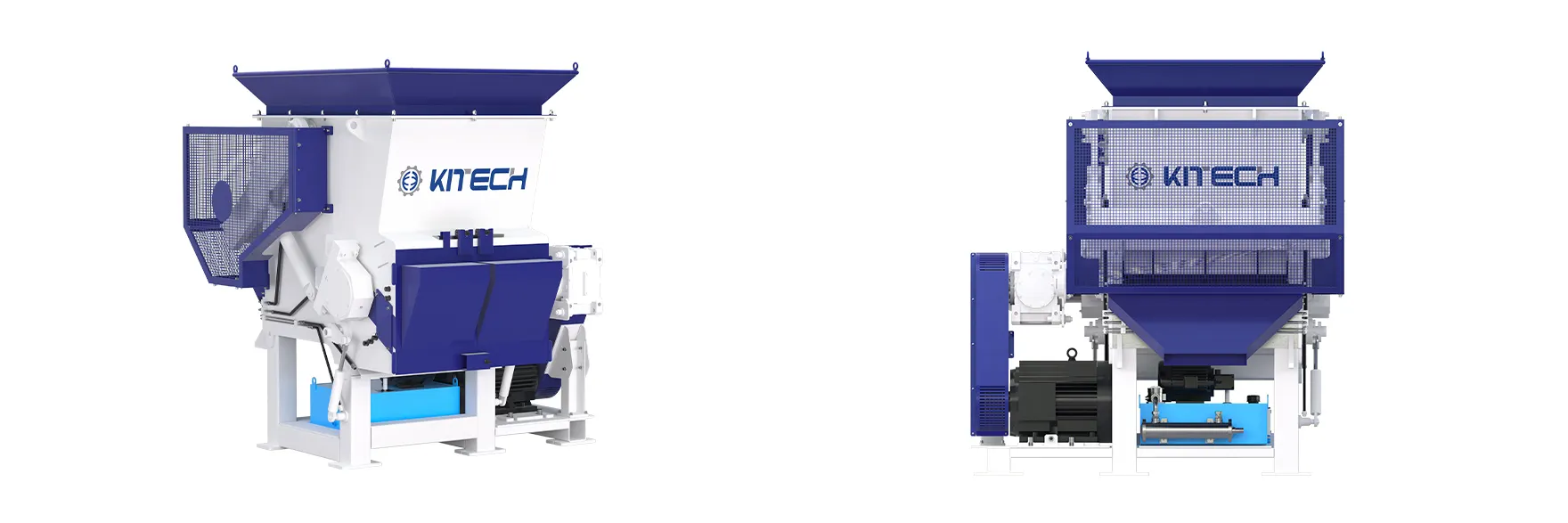

- Introduction to Plastic Shredder Machines

to Plastic Shredder Machines

Plastic shredder machines play a crucial role in the recycling industry by breaking down large pieces of plastic into smaller, more manageable chunks. These machines are essential for reducing the volume of plastic waste, making it easier to recycle and re-purpose. In this article, we will explore the benefits of plastic shredder machines and their impact on operational safety.

Plastic shredder machines are designed to handle a wide variety of plastic materials, including PET bottles, PVC, HDPE, and more. These machines are equipped with high-powered motors and sharp blades that are capable of efficiently shredding large volumes of plastic waste. The shredded plastic can then be melted down and used to create new products, reducing the need for virgin plastic materials.

One of the key benefits of using a plastic shredder machine is the increase in operational safety. By breaking down large pieces of plastic into smaller chunks, these machines reduce the risk of accidents and injuries that can occur when handling large, unwieldy pieces of plastic. Additionally, the use of a plastic shredder machine can also help to reduce the risk of fire hazards, as smaller pieces of plastic are less likely to ignite when exposed to heat or sparks.

Another important aspect of operational safety when using a plastic shredder machine is the proper maintenance and upkeep of the machine. Regular inspections and maintenance checks should be carried out to ensure that the machine is in good working condition and that all safety features are functioning properly. This includes checking the condition of the blades, ensuring that all safety guards are in place, and inspecting the motor and electrical components for any signs of wear or damage.

In addition to increasing operational safety, plastic shredder machines also offer environmental benefits. By reducing the volume of plastic waste, these machines help to alleviate the strain on landfills and reduce the amount of plastic pollution in the environment. This not only helps to protect the natural world but also reduces the carbon footprint associated with the production and disposal of plastic materials.

Furthermore, the use of plastic shredder machines can also lead to cost savings for recycling facilities and businesses. By efficiently breaking down plastic waste, these machines can increase the overall productivity of recycling operations, reducing the time and labor required to process large volumes of plastic. This can result in significant cost savings for businesses, making the investment in a plastic shredder machine a wise choice for those looking to improve their operational efficiency and reduce their environmental impact.

In conclusion, plastic shredder machines play a critical role in the recycling industry by breaking down large pieces of plastic into smaller, more manageable chunks. Not only do these machines increase operational safety by reducing the risk of accidents and injuries, but they also offer environmental benefits and cost savings for businesses. As the demand for plastic recycling continues to grow, the use of plastic shredder machines will undoubtedly become even more essential in the effort to reduce plastic waste and protect the environment.

- Potential Safety Hazards in Plastic Shredding Operations

Plastic shredder machines have become an increasingly popular tool in various industries, as they offer a convenient way to recycle and dispose of plastic waste. However, with the rise in their use, concerns have been raised about potential safety hazards in plastic shredding operations. This article aims to explore the potential safety hazards associated with using plastic shredder machines and the measures that can be taken to mitigate these risks.

One of the primary safety concerns in plastic shredding operations is the potential for accidents and injuries. The sharp blades and powerful motors used in these machines pose a significant risk to operators if they are not handled with care. Inexperienced or untrained personnel may be at a higher risk of injury, especially when they are not familiar with the correct operating procedures and safety protocols. Furthermore, the high-speed rotation of the blades and the force exerted by the machine can lead to serious injuries if proper precautions are not taken.

In addition to the risk of physical harm, there are also potential health hazards associated with plastic shredder machines. When plastic is shredded, it releases harmful fumes and particles into the air, which can be hazardous to the respiratory system if inhaled. This is particularly concerning in poorly ventilated areas, where the concentration of these fumes and particles can build up to dangerous levels. Inhaling these toxins over a prolonged period can lead to respiratory problems and other health issues for workers in the vicinity.

Another safety hazard in plastic shredding operations is the risk of fire and explosions. Plastic waste can be highly flammable, and when it is shredded, the heat generated by the machine can ignite the material. If the plastic waste contains any combustible materials or substances, the risk of fire or explosion increases significantly. This not only poses a danger to the operators but also to the surrounding environment and nearby structures. Without proper fire safety measures in place, the consequences of a fire or explosion in a plastic shredding facility can be catastrophic.

To address these potential safety hazards, several measures can be implemented to ensure the safe operation of plastic shredder machines. Firstly, adequate training and supervision are essential to ensure that operators understand how to use the machines safely and are aware of the potential risks involved. This includes proper machine maintenance, safe handling of the materials, and the correct use of personal protective equipment. Providing regular safety training and refresher courses can help to reinforce good safety practices and reduce the likelihood of accidents and injuries.

Furthermore, it is important to invest in quality equipment and machinery that meets the necessary safety standards. This includes the use of safety guards and emergency stop mechanisms to prevent accidents and injuries. Additionally, implementing effective ventilation systems and air quality monitoring can help to minimize the health risks associated with inhaling fumes and particles generated during the shredding process. It is also important to have clear and accessible emergency procedures in place, such as evacuation plans and firefighting equipment, to respond to any potential fire or explosion incidents.

In conclusion, while plastic shredder machines offer a convenient solution for recycling and disposing of plastic waste, it is important to be aware of the potential safety hazards associated with their use. By implementing proper safety measures, providing adequate training, and investing in quality equipment, the risks can be minimized, and plastic shredding operations can be carried out safely and efficiently. It is crucial for businesses and organizations that utilize these machines to prioritize the safety of their workers and the surrounding environment to prevent accidents and injuries.

- Benefits of Using a Plastic Shredder Machine for Operational Safety

A plastic shredder machine is an essential tool for businesses that deal with plastic waste on a regular basis. From recycling facilities to manufacturing plants, these machines are used to break down large plastic items into smaller pieces, making it easier to handle and process the material. While the primary goal of a plastic shredder machine is to increase efficiency and reduce waste, it also plays a crucial role in ensuring operational safety in the workplace.

One of the key benefits of using a plastic shredder machine is the reduction in occupational hazards. When dealing with large pieces of plastic, workers are at risk of injuries from handling sharp edges or heavy loads. By using a shredder machine, these risks are significantly minimized as the material is broken down into smaller, more manageable pieces. This not only protects workers from potential injuries but also creates a safer working environment overall.

In addition to reducing the risk of physical injuries, a plastic shredder machine also helps to mitigate the potential for fire hazards. When plastic waste is left in its original form, it can pose a significant fire risk, especially in facilities where other ignitable materials are present. By shredding the plastic into smaller pieces, the surface area exposed to heat sources is reduced, making it less likely to catch fire. This is particularly important in recycling facilities where large volumes of plastic are processed on a daily basis.

Furthermore, the use of a plastic shredder machine can also lead to improved air quality in the workplace. When plastic waste is broken down into smaller pieces, it minimizes the amount of dust and particles that are released into the air. This is crucial for businesses that prioritize the health and well-being of their employees. By reducing the amount of airborne particles, the risk of respiratory issues and other related health problems is significantly decreased.

Another aspect of operational safety that is positively impacted by the use of a plastic shredder machine is equipment maintenance. Without a shredder, the machinery used to process large plastic items is at risk of damage from the strain of handling bulky materials. This can lead to unexpected breakdowns and costly repairs. However, by utilizing a shredder to break down the plastic waste beforehand, the strain on other equipment is reduced, allowing for longer-lasting and more reliable machinery.

It is clear that the benefits of using a plastic shredder machine extend beyond just efficiency and waste reduction. By minimizing physical injuries, fire hazards, and air pollution, businesses can create a safer and healthier work environment for their employees. Additionally, the use of a shredder machine can also lead to lower maintenance costs for other equipment. Overall, investing in a plastic shredder machine is not only a smart business decision but also a proactive approach to ensuring operational safety.

- Important Safety Features to Look for in a Plastic Shredder Machine

Plastic shredder machines are essential tools for businesses and industries that deal with large quantities of plastic waste. They are used to break down and shred plastic materials into smaller pieces, making it easier to manage and recycle. However, the use of these machines comes with certain risks, and it's important for businesses to prioritize safety when using plastic shredder machines. In this article, we will discuss the important safety features to look for in a plastic shredder machine.

One of the most crucial safety features to consider when purchasing a plastic shredder machine is an emergency stop button. This feature allows operators to quickly shut down the machine in case of an emergency or if they notice any potential hazards. The emergency stop button should be easily accessible and clearly marked, ensuring that it can be activated without delay in the event of an emergency.

Another important safety feature to look for is automatic overload protection. Plastic shredder machines are designed to handle a specific capacity of materials. When overloaded, the machine can overheat or malfunction, posing a safety risk to operators. Automatic overload protection helps prevent these issues by shutting down the machine when it reaches its capacity, protecting both the operator and the machine from potential harm.

Additionally, it's essential to invest in a plastic shredder machine that comes with comprehensive safety guarding. This includes barriers, enclosures, and shields that prevent operators from coming into contact with the moving parts of the machine. These safety guards should be sturdy and securely fastened to the machine, providing a physical barrier between the operator and any potential hazards.

Furthermore, a plastic shredder machine should be equipped with safety interlocks. These interlocks ensure that the machine cannot be operated unless all safety guards and enclosures are in place. This prevents operators from bypassing safety measures and helps maintain a safe working environment.

In addition to these important safety features, it's also crucial to provide proper training for operators and establish clear safety protocols for using the plastic shredder machine. Operators should be trained on how to safely operate the machine, as well as how to recognize and respond to potential hazards. Regular safety inspections and maintenance should also be conducted to ensure that the machine is in optimal working condition.

In conclusion, plastic shredder machines can greatly increase operational safety if equipped with the right safety features. When looking to invest in a plastic shredder machine, it's important to prioritize safety and look for features such as emergency stop buttons, automatic overload protection, safety guarding, and safety interlocks. By implementing these safety measures and providing thorough training, businesses can ensure the safe and efficient operation of their plastic shredder machines, protecting both their operators and the equipment itself.

- Conclusion: Evaluating the Impact of a Plastic Shredder Machine on Operational Safety

Plastic shredder machines have become an essential tool in the recycling and waste management industry. These machines are used to break down large plastic materials into smaller pieces, making it easier to process and recycle them. However, there has been some debate on whether the use of plastic shredder machines increases operational safety. In this article, we will evaluate the impact of a plastic shredder machine on operational safety and determine if it truly improves workplace safety.

The Role of Plastic Shredder Machine in Operational Safety:

Plastic shredder machines are designed to handle large and bulky plastic materials, and they can be a potential hazard if not operated properly. However, when used correctly, these machines can significantly improve operational safety. By breaking down large plastic materials into smaller pieces, the risk of accidents and injuries associated with handling large and unwieldy plastic materials is greatly reduced. This not only protects the workers from harm, but it also ensures the overall safety and efficiency of the recycling process.

Evaluating the Impact of a Plastic Shredder Machine on Operational Safety:

To evaluate the impact of a plastic shredder machine on operational safety, it is important to consider several key factors. Firstly, the design and construction of the machine itself play a crucial role in ensuring safety. A well-designed and properly maintained machine will minimize the risk of accidents and injuries. It is also important to consider the training and experience of the operators. Proper training and adherence to safety protocols are essential in ensuring that the shredder machine is operated safely. Additionally, the use of safety guards and protective equipment further enhances the operational safety of the machine.

Case Study: A Plastic Recycling Facility’s Experience with a Shredder Machine:

To better understand the impact of a plastic shredder machine on operational safety, we conducted a case study at a plastic recycling facility. The facility had recently invested in a new plastic shredder machine and had observed a significant improvement in operational safety. The machine was equipped with safety guards and emergency stop features, and the operators had received thorough training on its safe operation. As a result, the facility reported a decrease in workplace accidents and injuries related to handling large plastic materials. The overall efficiency and productivity of the facility had also improved, as the shredder machine allowed for faster and safer processing of plastic materials.

In conclusion, the use of a plastic shredder machine can have a positive impact on operational safety when used correctly. Proper design, maintenance, operator training, and the use of safety features all contribute to the safe operation of the machine. The case study conducted at a plastic recycling facility demonstrated that a well-maintained and properly operated shredder machine can significantly reduce workplace accidents and injuries while also improving the efficiency of the recycling process. It is clear that when used responsibly, a plastic shredder machine can indeed increase operational safety in the recycling and waste management industry.

Conclusion

In conclusion, the use of a plastic shredder machine can indeed increase operational safety in a number of ways. Not only does it reduce the risk of accidents and injuries by effectively managing plastic waste, but it also minimizes the potential for physical strain on workers. Additionally, the proper disposal of plastic waste through shredding helps to mitigate environmental hazards and promotes a cleaner and healthier work environment. Therefore, investing in a plastic shredder machine is not only beneficial for operational safety, but also for overall efficiency and sustainability in the workplace. It is a win-win solution that should be seriously considered by businesses looking to prioritize safety and responsibility.