Does A Plastic Shredder Machine Enhance Material Recovery?

Welcome to our article on the effectiveness of plastic shredder machines in enhancing material recovery. In a world facing a growing plastic pollution crisis, the importance of efficient recycling and recovery methods cannot be overstated. In this article, we delve into the question of whether plastic shredder machines are truly a game-changer in the process of reclaiming valuable materials from plastic waste. Join us as we explore the potential benefits and limitations of these machines, and uncover their impact on material recovery efforts. Whether you are an industry professional, environmental activist, or simply interested in sustainability, this article is a must-read for anyone seeking to understand the role of plastic shredder machines in addressing our global recycling challenges.

- Understanding the Purpose of a Plastic Shredder Machine

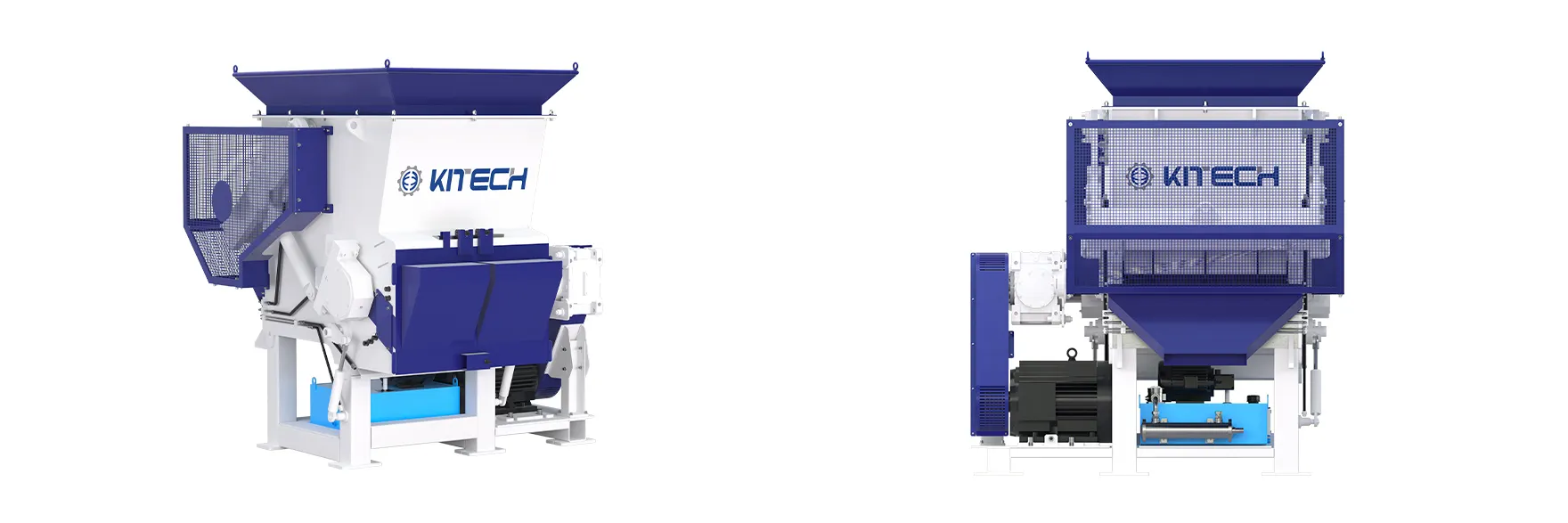

A plastic shredder machine is a powerful tool used in the recycling industry to break down large plastic materials into smaller, more manageable pieces. This process is crucial for enhancing material recovery and reducing the impact of plastic waste on the environment.

One of the primary purposes of a plastic shredder machine is to facilitate the recycling process. By breaking down plastic materials into smaller pieces, the machine makes it easier to sort and separate different types of plastics. This is essential for ensuring that the materials can be effectively recycled and reused, instead of ending up in landfills or polluting the environment.

Furthermore, a plastic shredder machine plays a vital role in reducing the volume of plastic waste. Large plastic items, such as bottles, containers, and packaging materials, can take up a significant amount of space in landfills if not properly processed. By shredding these items into smaller pieces, the machine helps to minimize the amount of space needed for storage and disposal, ultimately reducing the environmental impact of plastic waste.

In addition to enhancing material recovery and reducing waste volume, a plastic shredder machine also contributes to the overall sustainability of the recycling industry. By breaking down plastic materials, the machine makes it possible to create new products from recycled plastics. This not only conserves natural resources but also reduces the need for energy-intensive manufacturing processes, ultimately lowering the carbon footprint of plastic production.

There are several types of plastic shredder machines available, each designed for specific purposes and materials. For example, some machines are specifically engineered to handle soft plastics, such as polyethylene and polypropylene, while others are more suitable for rigid plastics, such as PET and PVC. It is essential to select the right type of shredder machine for the specific recycling needs and materials to ensure optimal performance and efficiency.

Furthermore, the size and capacity of the shredder machine are significant factors to consider. Larger industrial shredders are capable of processing high volumes of plastic materials, making them ideal for large-scale recycling facilities. In contrast, smaller, more compact shredders are suitable for smaller operations or businesses looking to manage their plastic waste more efficiently.

It is important to note that the proper maintenance and operation of a plastic shredder machine are crucial for maximizing its effectiveness and longevity. Regular maintenance, such as blade sharpening and lubrication, is essential for ensuring the machine continues to perform at its best. Additionally, proper operator training and safety protocols are critical for preventing accidents and injuries while operating the machine.

In conclusion, a plastic shredder machine plays a crucial role in enhancing material recovery, reducing waste volume, and promoting sustainability in the recycling industry. By breaking down large plastic materials into smaller pieces, the machine facilitates the recycling process, reduces the environmental impact of plastic waste, and enables the creation of new products from recycled plastics. Selecting the right type and size of shredder machine, as well as ensuring proper maintenance and operation, is essential for achieving optimal results in plastic recycling efforts.

- The Role of Material Recovery in Waste Management

The Role of Material Recovery in Waste Management

The role of material recovery in waste management is a crucial aspect of sustainable and environmentally responsible practices. With the increasing amount of waste being generated globally, it is imperative to implement efficient methods for recovering valuable materials from waste streams. In recent years, the use of plastic shredder machines has gained attention for their potential to enhance material recovery in waste management systems.

Plastic shredder machines are designed to efficiently and effectively break down plastic waste into smaller pieces, making it easier to separate and recover valuable materials. These machines come in various sizes and configurations, ranging from small-scale units for household use to large industrial-sized machines used in recycling facilities. Regardless of their size, plastic shredder machines play a significant role in the material recovery process by reducing the volume of plastic waste and preparing it for further processing.

One of the key benefits of using a plastic shredder machine in waste management is the ability to increase the recovery of valuable materials from plastic waste. By shredding plastic waste into smaller pieces, it becomes easier to sort and separate different types of plastics based on their properties. This allows for more efficient recovery of valuable plastic materials such as PET, HDPE, and PVC, which can be recycled and used in the production of new products. Additionally, the use of plastic shredder machines can help reduce the amount of plastic waste being sent to landfills, contributing to a more sustainable waste management approach.

Furthermore, plastic shredder machines can also help improve overall recycling efficiency by preparing plastic waste for downstream processing. Once the plastic waste has been shredded, it can be further processed using techniques such as washing, drying, and extrusion to produce high-quality recycled plastic materials. This not only reduces the environmental impact of plastic waste but also promotes the circular economy by closing the loop on plastic materials and reducing the reliance on virgin plastic production.

In addition to enhancing material recovery, plastic shredder machines can also contribute to the overall safety and cleanliness of waste management facilities. By breaking down plastic waste into smaller pieces, these machines can help reduce the risk of potential hazards and improve the overall working conditions for waste management personnel. Furthermore, the use of plastic shredder machines can also help minimize the transportation and storage costs associated with plastic waste, as the shredded material takes up less space and is easier to handle.

In conclusion, the role of material recovery in waste management is vital for promoting sustainable and responsible waste practices. The use of plastic shredder machines plays a significant role in enhancing material recovery by efficiently breaking down plastic waste and preparing it for further processing. These machines not only increase the recovery of valuable materials from plastic waste but also contribute to overall recycling efficiency and promote a more sustainable approach to waste management. As the global focus on reducing plastic waste intensifies, the role of plastic shredder machines in material recovery will continue to be a key component of waste management systems.

- Examining the Impact of a Plastic Shredder Machine on Material Recovery Processes

In recent years, the issue of plastic waste has become a prominent concern for environmentalists, policymakers, and the general public. The accumulation of plastic waste in landfills and oceans has led to a growing imperative for the development of more effective and efficient methods for recycling and material recovery. One such method that has gained attention is the use of plastic shredder machines, which are designed to break down plastic waste into smaller pieces in order to facilitate the recycling process. This article seeks to examine the impact of a plastic shredder machine on material recovery processes, and to consider whether the use of such technology can indeed enhance the recovery of plastic materials.

The plastic shredder machine is a powerful tool in the fight against plastic waste. By reducing plastic waste into smaller, more manageable pieces, shredders enable more efficient transportation and handling of materials, and can also help to reduce the volume of waste that needs to be processed. This can have significant benefits for material recovery facilities, which often struggle to manage the large volumes of plastic waste that are generated on a daily basis. Additionally, by breaking down plastic waste into smaller pieces, shredders can also make the recycling process more effective, as smaller pieces of plastic are easier to process and can be used to create a wider range of recycled products.

One of the key advantages of using a plastic shredder machine is the potential to increase the recovery of valuable materials from plastic waste. When plastic waste is shredded, it can be sorted more effectively, as smaller pieces are easier to identify and classify. This can help material recovery facilities to recover a greater quantity of high-quality plastic materials, which can then be recycled into new products. By increasing the recovery of valuable materials, shredders can help to improve the overall efficiency of the recycling process, and can also help to reduce the need for new plastic production, which has significant environmental benefits.

In addition to enhancing material recovery processes, plastic shredder machines can also have other positive impacts on the recycling industry. For example, by reducing the size of plastic waste, shredders can help to free up valuable storage space at material recovery facilities, and can also reduce the cost of transportation and handling of materials. This can help to make the recycling process more cost-effective and can also help to improve the overall efficiency of material recovery operations. Furthermore, by breaking down plastic waste into smaller pieces, shredders can also help to reduce the risk of contamination in recycled plastic materials, which can improve the quality of recycled products and make them more attractive to manufacturers and consumers.

In conclusion, the use of plastic shredder machines has the potential to significantly enhance material recovery processes and to improve the overall efficiency of the recycling industry. By breaking down plastic waste into smaller, more manageable pieces, shredders can help to increase the recovery of valuable materials, reduce the volume of waste that needs to be processed, and improve the quality of recycled products. As the issue of plastic waste continues to grow, the use of shredders could play a vital role in the development of more sustainable and effective recycling processes.

- Advantages and Limitations of Using a Plastic Shredder Machine for Material Recovery

Plastic waste has become a major environmental concern, with over 300 million tons of plastic being produced worldwide each year. As a result, there has been a growing interest in finding effective ways to recycle and recover materials from plastic waste. One method that has gained attention is the use of a plastic shredder machine for material recovery. In this article, we will discuss the advantages and limitations of using a plastic shredder machine for material recovery.

Advantages of Using a Plastic Shredder Machine

1. Reduced Volume: One of the main advantages of using a plastic shredder machine is that it helps in reducing the volume of plastic waste. The machine shreds the plastic into smaller pieces, making it easier to transport and store. This not only saves space but also reduces the overall cost of waste management.

2. Increased Material Recovery: A plastic shredder machine is effective in breaking down plastic waste into smaller pieces, making it easier to separate different types of plastics for recycling. This can lead to increased material recovery and higher quality recycled materials.

3. Versatility: Plastic shredder machines are versatile and can process a wide range of plastic materials, including bottles, containers, film, and more. This flexibility allows for a variety of plastics to be processed and recovered, increasing the overall efficiency of material recovery.

4. Cost-Effective: In the long run, using a plastic shredder machine can be cost-effective for businesses and organizations involved in material recovery. The reduced volume of plastic waste, increased material recovery, and versatility of the machine can lead to lower waste management costs and higher profits from recycled materials.

Limitations of Using a Plastic Shredder Machine

1. Energy Consumption: One of the limitations of using a plastic shredder machine is the amount of energy it requires to operate. These machines can be power-hungry, especially when processing large volumes of plastic waste. This can increase operational costs and contribute to energy consumption.

2. Maintenance and Upkeep: Like any other machinery, plastic shredder machines require regular maintenance and upkeep to ensure optimal performance. This can add to the overall cost of operating the machine and require additional resources in terms of time and manpower.

3. Noise and Pollution: Plastic shredder machines can be noisy and produce emissions during operation. This can lead to noise pollution and air pollution, especially in industrial settings. Measures need to be taken to mitigate these impacts on the environment and surrounding communities.

4. Limited Processing Capacity: Some plastic shredder machines have limited processing capacity, which means they may not be suitable for large-scale material recovery operations. This limitation can affect the overall efficiency and productivity of material recovery processes.

In conclusion, while using a plastic shredder machine for material recovery comes with several advantages, including reduced volume, increased material recovery, versatility, and cost-effectiveness, there are also limitations to consider, such as energy consumption, maintenance and upkeep, noise and pollution, and limited processing capacity. It is important for businesses and organizations to weigh the pros and cons before investing in a plastic shredder machine for material recovery, and to consider ways to mitigate any potential drawbacks.

- Considerations for Implementing a Plastic Shredder Machine in Material Recovery Facilities

Material recovery facilities (MRFs) play a critical role in the recycling process by sorting and processing waste materials to be re-used or repurposed. As the demand for efficient and effective recycling methods continues to grow, MRFs are constantly seeking new technologies to enhance their material recovery capabilities. One such technology that has gained attention in recent years is the plastic shredder machine.

A plastic shredder machine is a piece of equipment designed to break down large plastic items into smaller pieces, making them easier to handle and process in the recycling plant. This technology has the potential to significantly enhance the material recovery process by improving the efficiency and effectiveness of plastic waste management. However, the implementation of a plastic shredder machine in a MRF comes with several considerations that need to be carefully evaluated.

First and foremost, the cost of acquiring and installing a plastic shredder machine must be taken into account. While the initial investment may seem high, the long-term cost savings and increased processing efficiency make the machine a worthwhile investment for many MRFs. Additionally, the size and capacity of the machine must be aligned with the specific needs of the facility, taking into consideration the volume and type of plastic waste that is processed on a regular basis.

Another important consideration for implementing a plastic shredder machine in a MRF is the impact it will have on the overall recycling process. The machine must be integrated seamlessly into the existing workflow to ensure a smooth transition and minimal disruption to day-to-day operations. This may require adjustments to the layout of the facility and the training of personnel to operate and maintain the machine effectively.

Furthermore, the environmental impact of using a plastic shredder machine must be carefully evaluated. While the technology has the potential to increase the amount of plastic waste that can be recycled, it is important to consider the energy consumption and emissions associated with operating the machine. MRFs must balance the potential environmental benefits of implementing the machine with its overall impact on sustainability.

Additionally, the quality of the shredded plastic material produced by the machine is a crucial factor to consider. The end product must meet the standards and specifications required by manufacturers and buyers of recycled plastic material. Therefore, MRFs must ensure that the machine is capable of producing high-quality shredded plastic that can be successfully re-used or repurposed.

In conclusion, the implementation of a plastic shredder machine in a MRF has the potential to enhance material recovery and improve the overall efficiency of the recycling process. However, careful consideration and evaluation of various factors such as cost, impact on workflow, environmental concerns, and the quality of the end product are essential for successful implementation. With the right approach and careful planning, a plastic shredder machine can be a valuable addition to a MRF, contributing to the advancement of sustainable waste management practices.

Conclusion

In conclusion, the use of a plastic shredder machine does enhance material recovery in several ways. It helps to reduce the volume of plastic waste, making it easier to transport and process. Additionally, shredding plastic into smaller pieces makes it more accessible for recycling facilities to transform it into new products. This ultimately contributes to a more sustainable and efficient approach to managing plastic waste. As we continue to seek solutions for reducing plastic pollution and promoting circular economy principles, the use of plastic shredder machines will undoubtedly play a crucial role in enhancing material recovery and advancing towards a more sustainable future.