Can A Plastic Shredder Machine Save Space In Your Factory?

Are you looking for a solution to save space in your factory? Look no further! In this article, we will explore the potential benefits of a plastic shredder machine in reducing clutter and optimizing space in your industrial setting. Whether you're running a small-scale operation or a large manufacturing facility, this innovative technology could be the key to unlocking more floor space and improving efficiency. Read on to discover how a plastic shredder machine can revolutionize your factory layout and enhance productivity.

- Introduction to Plastic Shredder Machines

to Plastic Shredder Machines

Plastic waste has become a huge problem for factories and businesses around the world. The amount of plastic waste being generated is increasing each year and it’s becoming more difficult to properly dispose of it. This is where a plastic shredder machine can come in handy. In this article, we will explore the introduction to plastic shredder machines and how they can save space in your factory.

What is a Plastic Shredder Machine?

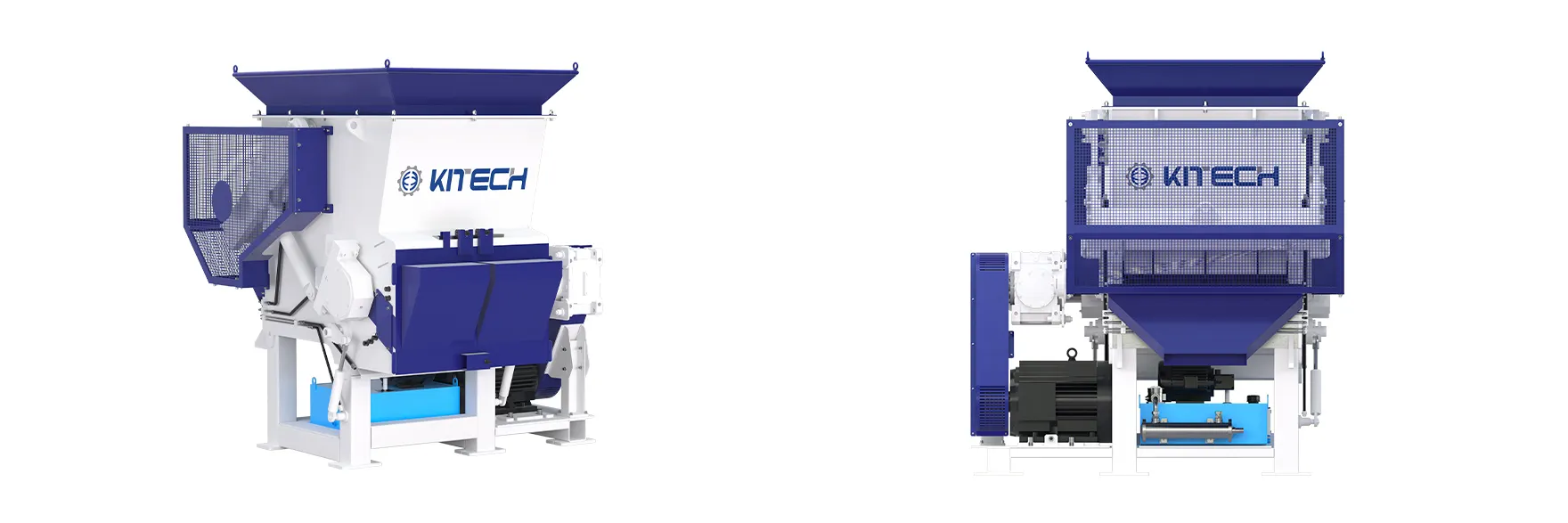

A plastic shredder machine is a piece of equipment used to reduce the size of large plastic materials such as plastic bottles, plastic drums, and other plastic items. The machine works by shredding the plastic into small pieces, which can then be recycled or disposed of in a more efficient manner.

These machines come in various sizes and are designed to handle different types and quantities of plastic waste. Some machines are capable of shredding large volumes of plastic waste, while others are more suitable for smaller quantities.

How Can a Plastic Shredder Machine Save Space in Your Factory?

One of the main benefits of using a plastic shredder machine is that it can help save space in your factory. This is because the machine is able to reduce the size of the plastic waste, making it easier to store and transport. Instead of dealing with large, bulky plastic items, you can have smaller, more manageable pieces that take up less space.

Additionally, by reducing the size of the plastic waste, you can also reduce the number of trips required to transport the waste to a recycling or disposal facility. This can save both time and money, as well as reduce the environmental impact of transportation.

Furthermore, a plastic shredder machine can also help to create a more organized and efficient waste management system in your factory. By shredding the plastic waste on-site, you can more easily separate and categorize the materials for recycling or disposal. This can streamline the waste management process, making it easier to handle and process the plastic waste.

Benefits of Using a Plastic Shredder Machine

In addition to saving space in your factory, there are several other benefits to using a plastic shredder machine. One of the main benefits is that it can help to reduce the amount of plastic waste that ends up in landfills or incinerators. By shredding the plastic waste and recycling it, you can help to minimize the environmental impact of plastic pollution.

Furthermore, using a plastic shredder machine can also help to save money in the long run. By recycling the shredded plastic, you can reduce the amount of money spent on purchasing new plastic materials. Additionally, some recycling facilities may also pay for the shredded plastic, providing an additional source of income for your factory.

In conclusion, a plastic shredder machine can be a valuable investment for factories and businesses looking to improve their waste management processes. Not only can a plastic shredder machine help to save space in your factory, but it can also reduce the environmental impact of plastic pollution and save money in the long run. If you are looking for a way to better manage your plastic waste, consider investing in a plastic shredder machine for your factory.

- Benefits of Using a Plastic Shredder Machine

Plastic waste is a growing concern for manufacturing facilities around the world. With the increasing focus on sustainable and environmentally-friendly practices, businesses are exploring various ways to reduce their impact on the environment, including reducing the amount of plastic waste they produce. One effective solution to this problem is the use of a plastic shredder machine. These machines offer a range of benefits for factories, including the ability to save space, improve efficiency, and reduce waste.

One of the primary benefits of using a plastic shredder machine in a factory setting is the potential to save space. Plastic waste can take up a significant amount of valuable floor space, especially in facilities that produce large quantities of plastic products. By using a shredder to break down this waste into smaller, more manageable pieces, businesses can free up space that can be used for other productive purposes. This can lead to better organization and improved workflow within the facility, ultimately contributing to a more efficient and productive operation.

In addition to space-saving benefits, plastic shredder machines can also improve efficiency in a factory setting. When plastic waste is left unprocessed, it can create a cluttered and disorganized environment that may hinder the productivity of workers. By properly shredding and disposing of this waste, businesses can create a cleaner and more organized workspace that allows for easier movement and access to equipment and materials. This, in turn, can lead to increased productivity and a more streamlined manufacturing process.

Furthermore, the use of a plastic shredder machine can also contribute to a reduction in waste and environmental impact. By breaking down plastic waste into smaller pieces, businesses can more effectively manage and recycle this material, reducing the amount of waste sent to landfills. Additionally, some plastic shredder machines are capable of producing uniform and consistent output, which can be more easily recycled or repurposed for other uses. This can help businesses minimize their environmental footprint and demonstrate a commitment to sustainable practices.

Another advantage of using a plastic shredder machine is the potential for cost savings. In addition to the space-saving benefits mentioned earlier, businesses can also save on costs associated with waste disposal. By reducing the volume of plastic waste that needs to be hauled away or processed by outside services, businesses can potentially lower their waste management expenses. Additionally, the ability to repurpose shredded plastic material for recycling or other uses can contribute to cost savings and potentially create new revenue streams for the business.

Overall, the use of a plastic shredder machine can offer numerous benefits for manufacturing facilities looking to improve their environmental impact, efficiency, and bottom line. By investing in this technology, businesses can save space, improve organization and productivity, reduce waste, and even save on costs. With the growing focus on sustainability and responsible waste management, the use of a plastic shredder machine is an effective solution for businesses looking to make a positive impact on the environment while improving their operations.

- How a Plastic Shredder Machine Can Save Space in Your Factory

Plastic waste is a major issue for many manufacturing facilities, taking up valuable space and creating a potential hazard for employees. However, a plastic shredder machine could be the solution to this problem, by efficiently reducing the size of plastic waste and saving space in your factory.

First and foremost, a plastic shredder machine is designed to break down plastic materials into smaller pieces, making it easier to store and transport. This can be especially beneficial for facilities that have limited space for waste storage, as the shredded plastic can be compressed into a more manageable size, freeing up valuable floor space for other purposes.

In addition to saving space, a plastic shredder machine can also help improve the overall efficiency of a factory. By reducing the size of plastic waste, the machine can minimize the frequency of waste removal, saving time and labor costs. This can ultimately lead to increased productivity, as employees can focus on more important tasks rather than constantly managing waste disposal.

Furthermore, a plastic shredder machine can also contribute to a safer working environment. Large amounts of unshredded plastic waste can pose a safety risk, as it can create obstacles and potential tripping hazards in the factory. By shredding the plastic waste into smaller pieces, the risk of accidents and injuries can be significantly reduced, creating a more secure workplace for employees.

Moreover, the use of a plastic shredder machine can also have a positive impact on the environment. By efficiently reducing the size of plastic waste, the machine can promote responsible waste management practices, leading to less environmental impact. This is especially important in today's society, where there is an increasing focus on sustainability and reducing the carbon footprint.

When considering investing in a plastic shredder machine for your factory, it is important to look for a machine that meets your specific needs. Some factors to consider include the capacity and throughput of the machine, as well as its size and power requirements. It is also crucial to ensure that the machine is properly maintained and operated, to maximize its efficiency and longevity.

In conclusion, a plastic shredder machine can be a valuable asset for any manufacturing facility, offering a range of benefits including space-saving, improved efficiency, safety, and environmental responsibility. By investing in a high-quality machine and implementing proper maintenance and operation protocols, you can maximize the value of a plastic shredder machine and make a positive impact on your factory operations.

- Choosing the Right Plastic Shredder Machine for Your Factory

Choosing the Right Plastic Shredder Machine for Your Factory

As the demand for plastic recycling continues to grow, many factories are turning to plastic shredder machines to help save space and streamline their operations. These machines offer an efficient and cost-effective way to reduce the size of plastic waste, making it easier to store and transport for recycling. But with so many options available on the market, choosing the right plastic shredder machine for your factory can be a daunting task.

When it comes to selecting a plastic shredder machine, there are several factors that you need to consider. The first and most important consideration is the type of plastic waste that your factory generates. Different types of plastic require different types of shredders, so it's crucial to choose a machine that is designed to handle the specific materials that your factory produces. For example, if your factory primarily processes PET bottles, you will need a shredder that is specifically designed to handle this type of plastic.

In addition to the type of plastic waste, you also need to consider the volume of waste that your factory generates. Some plastic shredder machines are designed for light-duty use, while others are capable of handling large volumes of plastic waste on a daily basis. It's important to choose a machine that can keep up with the demands of your factory to ensure maximum efficiency.

Another important factor to consider is the size of the shredder machine. Space is often at a premium in factory settings, so it's essential to choose a machine that will fit comfortably within your existing space constraints. Some shredder machines are small and compact, while others are larger and more suitable for heavy-duty use. Consider the available space in your factory and choose a machine that will not only fit within your space but also allow for easy access and maintenance.

When it comes to the performance of a plastic shredder machine, it's important to consider factors such as shredding capacity, speed, and power consumption. A machine with a higher shredding capacity will be able to process larger volumes of plastic waste in a shorter amount of time, improving overall efficiency. Similarly, a shredder with a higher motor power will be able to handle tougher materials and operate more smoothly. It's important to balance these factors with your specific production needs to find the right machine for your factory.

Finally, consider the maintenance and support options available for the plastic shredder machine. Regular maintenance is essential to keep the machine in optimal working condition, so it's important to choose a machine that is easy to maintain and comes with reliable support options. Look for shredder machines that offer easy access to key components for maintenance and include a warranty or support plan for added peace of mind.

In conclusion, choosing the right plastic shredder machine for your factory is a crucial decision that can have a significant impact on your operations. Consider factors such as the type and volume of plastic waste, available space, performance, and maintenance options to find a machine that meets your specific needs. With the right machine in place, you can save space, improve efficiency, and contribute to a more sustainable approach to plastic waste management in your factory.

- Implementing a Plastic Shredder Machine in Your Factory

Implementing a Plastic Shredder Machine in Your Factory

In today's industrial settings, space is a valuable commodity. Manufacturers are constantly searching for ways to optimize their workspace and increase efficiency. One solution that many factories are turning to is the implementation of a plastic shredder machine. These innovative machines offer numerous benefits, including space savings, waste reduction, and improved sustainability. In this article, we will explore the advantages of integrating a plastic shredder machine into your factory and how it can revolutionize your operations.

Plastic shredder machines are designed to efficiently break down plastic waste into smaller, more manageable pieces. These machines come in various sizes and configurations, making them suitable for a wide range of industrial applications. By implementing a plastic shredder machine in your factory, you can significantly reduce the amount of space that is taken up by plastic waste. Rather than storing bulky plastic materials, you can turn them into compacted shreddings, freeing up valuable space for other essential equipment or production lines.

Furthermore, a plastic shredder machine can also streamline waste management processes in your factory. Instead of having to dispose of large, unwieldy plastic materials, these machines can shred them into easily transportable and recyclable particles, reducing the need for frequent waste pickups and eliminating the clutter caused by bulky plastic waste. This not only saves time and resources but also contributes to a cleaner and more organized work environment.

Another significant advantage of implementing a plastic shredder machine is the substantial reduction in waste generation. By breaking down plastic materials into smaller pieces, these machines enable factories to manage their plastic waste more efficiently. This can result in a decreased need for landfill space, lower waste disposal costs, and a reduced environmental impact. In a society increasingly focused on sustainability, having a plastic shredder machine in your factory can help you minimize your carbon footprint and demonstrate your commitment to environmental responsibility.

In addition to the immediate benefits of space savings and waste reduction, a plastic shredder machine can also contribute to long-term cost savings for your factory. By optimizing space and streamlining waste management processes, you can improve operational efficiency and reduce overhead expenses. Furthermore, the ability to repurpose shredded plastic materials for recycling or resale can create new revenue streams for your business, offsetting the initial investment in the shredder machine and potentially generating additional income.

When implementing a plastic shredder machine in your factory, it is essential to consider factors such as the volume and type of plastic waste generated, the required shredding capacity, and the available space for the machine. Additionally, maintenance and safety considerations should be taken into account to ensure the smooth and safe operation of the shredder machine. By carefully evaluating your specific needs and consulting with experts in the field, you can select a shredder machine that is tailored to your factory's requirements and seamlessly integrates into your operations.

In conclusion, a plastic shredder machine holds the potential to revolutionize your factory's waste management and space optimization strategies. By implementing this innovative equipment, you can save valuable space, reduce waste generation, improve sustainability, and realize long-term cost savings. With the right expertise and a well-thought-out plan, integrating a plastic shredder machine into your factory can be a game-changer for your business.

Conclusion

In conclusion, a plastic shredder machine can indeed save space in your factory. By efficiently breaking down large plastic materials into smaller pieces, it allows for better organization and storage of waste materials. Additionally, the compact size of the shredded plastic can free up valuable floor space in the factory, creating a more functional and streamlined working environment. Not only does the shredder machine save space, but it also contributes to waste reduction and recycling efforts, making it a valuable investment for any factory looking to improve their operations and environmental impact. So, if you're looking to optimize space and improve your waste management processes, investing in a plastic shredder machine could be the solution you've been looking for.