It Is Worth Investing In A High-Output Plastic Pelletizing Machine?

Welcome to our article on the key question of whether it is worth investing in a high-output plastic pelletizing machine. As the demand for recycled plastic products continues to grow, businesses are increasingly looking for efficient and cost-effective ways to process plastic waste. In this article, we will explore the benefits of investing in a high-output plastic pelletizing machine and how it can help businesses meet their production needs while also contributing to environmental sustainability. Whether you are a plastic manufacturer, recycling facility, or a business looking to improve your sustainability efforts, this article will provide valuable insights into the potential return on investment in a high-output plastic pelletizing machine.

Understanding the Importance of Plastic Pelletizing

Plastic pelletizing is an essential process in the recycling and manufacturing industry, as it plays a crucial role in converting plastic waste into useful raw materials. Investing in a high-output plastic pelletizing machine can bring numerous benefits to businesses and the environment. In this article, we will explore the importance of plastic pelletizing and highlight the advantages of investing in a high-quality pelletizing machine.

Plastic pelletizing is the process of transforming plastic waste into small, uniform pellets that can be used as raw materials in various industries. This process is essential for recycling plastic waste and reducing the environmental impact of plastic pollution. By pelletizing plastic waste, it can be repurposed into new products, reducing the reliance on virgin plastic materials and minimizing the amount of plastic ending up in landfills or oceans.

One of the key benefits of plastic pelletizing is that it allows for the efficient recycling of plastic waste. Instead of disposing of plastic waste, it can be collected, sorted, and pelletized, turning it into a valuable resource for manufacturers. This not only reduces the demand for new plastic production but also helps to conserve natural resources and reduce energy consumption. Investing in a high-output plastic pelletizing machine can significantly increase the efficiency and output of the pelletizing process, making it a worthwhile investment for businesses looking to improve their recycling capabilities.

Moreover, plastic pelletizing helps to create a sustainable and circular economy for plastic materials. By recycling plastic waste into pellets, it can be used to manufacture a wide range of products, including plastic bags, containers, and packaging materials. This closed-loop system reduces the need for new plastic production and minimizes the environmental impact of plastic waste. A high-quality pelletizing machine is essential for producing uniform and high-quality pellets that meet the specifications of manufacturers, ensuring that the recycled plastic can be used in various applications.

In addition to environmental benefits, investing in a high-output plastic pelletizing machine can also bring economic advantages to businesses. By recycling plastic waste and producing high-quality pellets, companies can reduce their raw material costs, increase their production efficiency, and enhance their sustainability credentials. Furthermore, the demand for recycled plastic materials is growing, as more industries and consumers prioritize environmentally friendly products. Therefore, businesses that invest in plastic pelletizing machines can tap into a growing market for recycled plastics, creating new opportunities for revenue and growth.

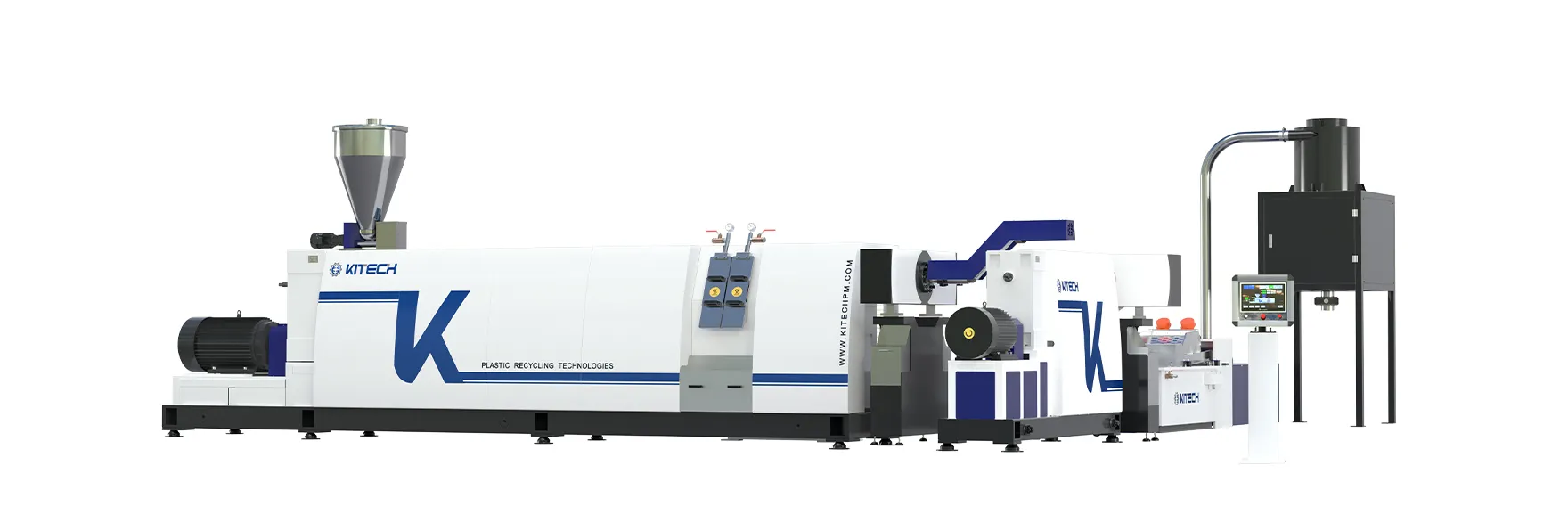

When considering the investment in a plastic pelletizing machine, it is essential to choose a high-quality and high-output machine that meets the specific needs and requirements of the business. Factors to consider include the capacity, efficiency, and versatility of the machine, as well as the quality of the pellets produced. Investing in a reliable and efficient machine can deliver long-term benefits, including reduced operating costs, increased productivity, and a positive impact on the environment.

In conclusion, the importance of plastic pelletizing cannot be understated, as it is a critical process in the recycling and manufacturing industry. By investing in a high-output plastic pelletizing machine, businesses can enhance their recycling capabilities, reduce their environmental impact, and create new opportunities for growth and sustainability. It is worth considering the long-term benefits and advantages of investing in a high-quality pelletizing machine, as it can bring significant value to businesses and the environment.

Benefits of Investing in a High-Output Machine

When it comes to plastic recycling, a high-output plastic pelletizing machine can be a game-changer. This article will explore the benefits of investing in a high-output machine, and why it is worth the investment for businesses in the plastic recycling industry.

Increased Productivity

One of the key benefits of investing in a high-output plastic pelletizing machine is the increased productivity it offers. These machines are designed to process a larger volume of plastic material in a shorter amount of time, allowing for greater efficiency and output. This means that businesses can process more plastic material and produce a higher volume of pellets, leading to increased profits and a more competitive edge in the market.

Cost Savings

Another advantage of high-output machines is the potential for cost savings. While the initial investment in a high-output plastic pelletizing machine may be higher than that of a standard machine, the increased productivity and efficiency can lead to significant long-term savings. Businesses can save on labor costs, as the machine requires less time and manpower to operate, and can also benefit from reduced energy and maintenance costs.

Improved Quality

High-output plastic pelletizing machines are designed to produce consistent and high-quality pellets. The advanced technology and precision of these machines ensure that the pellets are uniform in size and shape, making them ideal for use in various applications. This can lead to increased customer satisfaction and loyalty, as businesses can deliver a superior product to their clients.

Diverse Material Compatibility

Another benefit of investing in a high-output machine is the ability to process a wide range of plastic materials. These machines are equipped to handle various types of plastic, including HDPE, LDPE, PP, and more, allowing businesses to expand their capabilities and cater to a broader market. This versatility can open up new opportunities and revenue streams for businesses in the plastic recycling industry.

Environmental Impact

In addition to the business benefits, investing in a high-output plastic pelletizing machine can also have a positive environmental impact. By processing a larger volume of plastic material, businesses can contribute to reducing plastic waste and promoting sustainability. The production of high-quality pellets also supports the reuse and recycling of plastic, further minimizing environmental impact.

Market Competitiveness

Ultimately, investing in a high-output plastic pelletizing machine can help businesses maintain a competitive edge in the market. The increased productivity, cost savings, improved quality, diverse material compatibility, and environmental benefits can all contribute to a stronger position in the industry. This can lead to greater opportunities for growth, expansion, and success for businesses in the plastic recycling sector.

In conclusion, the benefits of investing in a high-output plastic pelletizing machine are clear. From increased productivity and cost savings to improved quality and environmental impact, these machines offer a range of advantages for businesses in the plastic recycling industry. For those looking to stay ahead in the market and maximize their potential, investing in a high-output machine is undoubtedly worth considering.

Factors to Consider When Choosing a Plastic Pelletizing Machine

Plastic pelletizing machines are essential equipment in the plastic manufacturing industry. They are used to convert plastic waste or regrind into uniform-sized pellets, which can be used as raw material for various plastic products. When investing in a plastic pelletizing machine, it is crucial to consider several factors to ensure that you get the best machine for your specific needs. In this article, we will discuss the key factors to consider when choosing a plastic pelletizing machine.

One of the most important factors to consider when choosing a plastic pelletizing machine is the output capacity. The output capacity of the machine will determine the amount of pellets it can produce in a given period. If you have a high production demand, you will need a machine with a high output capacity to meet your production needs. On the other hand, if you have a small-scale operation, a machine with a lower output capacity may be sufficient.

Another important factor to consider is the type of plastic materials you will be pelletizing. Different plastic materials have different properties, and not all pelletizing machines are suitable for all types of plastics. Some machines are designed to handle specific types of plastics, while others are more versatile and can handle a wider range of materials. It is essential to choose a machine that is compatible with the type of plastic materials you will be working with to ensure efficient pelletizing.

The quality of the pellets produced by the machine is also a crucial factor to consider. High-quality pellets are essential for producing high-quality plastic products. Look for a machine that is capable of producing uniform-sized pellets with consistent properties. This will help you maintain the quality of your plastic products and ensure customer satisfaction.

The ease of operation and maintenance of the machine should also be taken into consideration. A machine that is easy to operate and maintain will save you time and effort in the long run. Look for a machine that is user-friendly and comes with clear instructions for operation and maintenance. Additionally, consider the availability of spare parts and technical support for the machine to ensure that you can quickly address any issues that may arise.

The cost of the machine is another important factor to consider. It is essential to compare the cost of different machines and consider the value they offer in terms of output capacity, quality, and ease of operation. While it may be tempting to opt for the cheapest option, it is important to consider the long-term costs and benefits of the machine.

In conclusion, investing in a high-output plastic pelletizing machine can be a worthwhile investment for plastic manufacturers. When choosing a machine, consider factors such as output capacity, compatibility with plastic materials, pellet quality, ease of operation and maintenance, and overall cost. By carefully considering these factors, you can select a machine that meets your specific needs and helps you achieve efficient and high-quality plastic pelletizing.

Long-Term Viability and Return on Investment

Investing in a high-output plastic pelletizing machine can be a significant decision for any business involved in plastic manufacturing or recycling. When considering such an investment, it is crucial to assess the long-term viability and return on investment of the machine. In this article, we will delve into the various factors that contribute to the long-term viability and return on investment of a high-output plastic pelletizing machine.

One of the key factors to consider when evaluating the long-term viability of a plastic pelletizing machine is its efficiency and productivity. High-output machines are designed to process large quantities of plastic materials, resulting in a higher production capacity. This can lead to increased output and ultimately higher profits for the business. Additionally, the efficiency of the machine in processing and pelletizing plastic materials can lead to cost savings in terms of labor and energy consumption, further contributing to its long-term viability.

Another important aspect to consider when assessing the long-term viability of a plastic pelletizing machine is its durability and reliability. Investing in a high-quality machine that is built to last can minimize the need for frequent repairs and maintenance, ultimately reducing downtime and maximizing the machine's operational efficiency. This, in turn, can positively impact the return on investment by ensuring consistent production output and minimizing disruptions in the production process.

Furthermore, the flexibility and adaptability of a plastic pelletizing machine are crucial in determining its long-term viability. Machines that are designed to accommodate a wide range of plastic materials and have the capability to produce different pellet sizes can cater to diverse customer needs and market demands. This flexibility can contribute to the machine's longevity and relevance in the industry, thus enhancing its long-term viability.

In addition to the long-term viability of a plastic pelletizing machine, it is essential to assess its return on investment. The initial capital investment in a high-output machine can be substantial, but the potential for long-term returns must be carefully evaluated. Factors such as the machine's production capacity, operational efficiency, and cost savings need to be considered when calculating the return on investment.

One of the primary ways a high-output plastic pelletizing machine contributes to a favorable return on investment is through increased production output. By processing larger quantities of plastic materials in a more efficient manner, the machine can significantly enhance the overall production capacity, leading to higher sales and revenue generation. This, in turn, can contribute to a faster recoup of the initial investment and ongoing profitability.

Furthermore, the cost savings associated with efficient processing and lower energy consumption can positively impact the return on investment of a plastic pelletizing machine. Reduced operating costs can contribute to higher profit margins and quicker returns on the initial investment. Additionally, the potential for attracting new customers and expanding market reach through the machine's flexibility and adaptability can further enhance its return on investment.

In conclusion, investing in a high-output plastic pelletizing machine can offer significant long-term viability and return on investment for businesses involved in plastic manufacturing or recycling. By carefully evaluating factors such as efficiency, productivity, durability, flexibility, and return on investment, businesses can make informed decisions when considering such an investment. Ultimately, a well-chosen plastic pelletizing machine can contribute to increased production output, cost savings, and overall profitability, making it a worthwhile investment for the future.

Sustainable Solutions for Plastic Recycling

In today's world, the issue of plastic pollution has become a significant concern for the environment and society as a whole. With the increasing use of plastic products, there is a growing demand for sustainable solutions for plastic recycling. One such solution is the use of high-output plastic pelletizing machines, which offer an efficient and effective way to recycle plastic waste.

Plastic pelletizing machines are a key component in the plastic recycling process. These machines are designed to convert plastic waste into small, uniform pellets that can be used to manufacture new plastic products. By using a plastic pelletizing machine, plastic waste can be repurposed and utilized, reducing the amount of plastic that ends up in landfills and oceans.

Investing in a high-output plastic pelletizing machine has many advantages. One of the main benefits is the ability to process a large volume of plastic waste. These machines are designed to handle high volumes of plastic material, making them ideal for commercial and industrial recycling operations. With a high-output machine, businesses can process large quantities of plastic waste efficiently, reducing the need for manual labor and increasing productivity.

In addition to processing large volumes of plastic waste, high-output pelletizing machines also offer a high degree of efficiency. These machines are designed to operate continuously, with minimal downtime, allowing for a consistent and reliable recycling process. This efficiency not only saves time and labor costs but also helps to reduce energy consumption and overall operational costs.

Furthermore, high-output plastic pelletizing machines are designed to produce high-quality plastic pellets. The pellets produced by these machines are uniform in size and shape, making them ideal for use in the manufacturing of new plastic products. This high quality ensures that the recycled plastic can be used in a wide range of applications, from packaging and construction to automotive and consumer goods.

Another important aspect of investing in a high-output plastic pelletizing machine is the environmental benefits. By recycling plastic waste, businesses can reduce their carbon footprint and minimize the impact on the environment. This sustainable approach to plastic recycling helps to conserve natural resources and reduce the amount of plastic waste that ends up in landfills and oceans.

In conclusion, investing in a high-output plastic pelletizing machine is a worthwhile endeavor for businesses looking to implement sustainable solutions for plastic recycling. These machines offer a range of benefits, including the ability to process large volumes of plastic waste, high efficiency, and the production of high-quality plastic pellets. By utilizing a plastic pelletizing machine, businesses can contribute to the global effort to reduce plastic pollution and create a more sustainable future.

Conclusion

In conclusion, the decision to invest in a high-output plastic pelletizing machine is definitely worth considering for any business involved in plastic recycling or manufacturing. With its ability to increase productivity, improve quality of plastic pellets, and reduce operational costs, a high-output machine can bring numerous benefits to your operations. Whether you are a small-scale recycler or a large-scale manufacturer, the potential return on investment and long-term savings make it a smart choice to invest in a high-output plastic pelletizing machine. By staying ahead of the competition and maximizing the value of your plastic waste, this investment can ultimately contribute to a more sustainable and profitable future for your business.