It Is Cost-Effective To Invest In A High-Quality Plastic Pelletizing Machine?

Are you considering investing in a plastic pelletizing machine, but unsure about the potential costs and benefits? Look no further! In this article, we will explore the cost-effectiveness of investing in a high-quality plastic pelletizing machine. Whether you are a small business or a large industrial operation, understanding the financial implications of this investment is crucial. Join us as we delve into the factors that make this investment worthwhile and the long-term benefits it can bring.

- Understanding the Importance of Plastic Pelletizing Machines

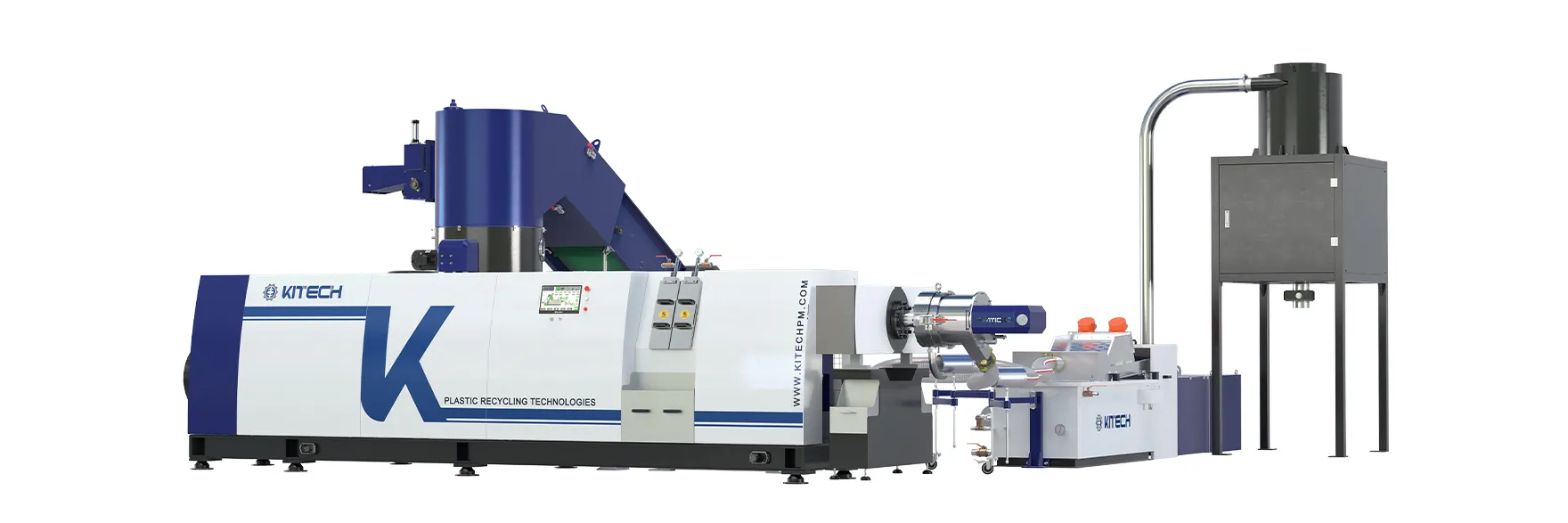

In today's world, the importance of plastic pelletizing machines cannot be overstated. These machines play a crucial role in the recycling and manufacturing processes of plastic products, making them an essential investment for any business involved in the production or processing of plastics.

Plastic pelletizing machines are used to convert plastic waste and scrap materials into small, uniform pellets that can then be used to manufacture new plastic products. This process is vital for not only reducing the amount of plastic waste in the environment but also for creating new materials that can be used in a wide range of industries.

One of the key benefits of investing in a high-quality plastic pelletizing machine is its cost-effectiveness. While the initial investment in a pelletizing machine may seem significant, the long-term savings and benefits far outweigh the upfront costs. By recycling plastic waste and converting it into reusable pellets, businesses can significantly reduce their reliance on virgin plastic materials, which can be expensive to procure. This not only helps save money in the long run but also reduces the environmental impact of plastic production.

Furthermore, plastic pelletizing machines offer a higher level of efficiency and consistency in the pelletization process. These machines are designed to process various types of plastic materials, including polyethylene, polypropylene, and polystyrene, among others, ensuring that businesses can recycle and transform a wide range of plastic waste into usable pellets. This versatility is essential for businesses that deal with different types of plastic waste and scraps, as it allows them to maximize the value of their materials and minimize waste.

Additionally, investing in a high-quality plastic pelletizing machine can also lead to increased productivity and reduced labor costs. These machines are designed to automate the pelletization process, reducing the need for manual labor and streamlining operations. This not only saves time and resources but also improves the overall efficiency of the recycling and manufacturing processes.

Another important aspect of plastic pelletizing machines is their contribution to environmental sustainability. By recycling plastic waste and converting it into reusable pellets, businesses can significantly reduce their carbon footprint and minimize the environmental impact of plastic production. This is essential in today's world, where environmental concerns are becoming more prominent, and businesses are increasingly expected to adopt sustainable practices.

In conclusion, it is evident that investing in a high-quality plastic pelletizing machine is both cost-effective and essential for businesses involved in the production or processing of plastics. These machines offer a wide range of benefits, including cost savings, increased efficiency, and environmental sustainability, making them a valuable asset for any business. Whether it's reducing plastic waste, improving productivity, or meeting environmental standards, plastic pelletizing machines are a crucial tool for achieving success in today's plastic industry.

- Advantages of Investing in High-Quality Plastic Pelletizing Machines

Investing in a high-quality plastic pelletizing machine can offer numerous advantages for businesses in the plastic recycling industry. These machines are designed to efficiently convert plastic waste into high-quality pellets, which can be used in the production of new plastic products. In this article, we will explore the various benefits of investing in high-quality plastic pelletizing machines and why they are a cost-effective option for businesses.

One of the main advantages of investing in a high-quality plastic pelletizing machine is the ability to increase the overall efficiency of the plastic recycling process. These machines are designed to handle large volumes of plastic waste and can quickly and effectively convert it into pellets. This can help businesses streamline their recycling operations and reduce the amount of time and labor required to process plastic waste. Additionally, high-quality pelletizing machines are built to last, reducing the need for frequent repairs and maintenance, further increasing operational efficiency.

Another advantage of investing in a high-quality plastic pelletizing machine is the ability to produce high-quality pellets. These machines are designed to create uniform and consistent pellets, which can be used in the production of new plastic products. This can help businesses maintain high standards of quality in their production processes, ensuring that the pellets they produce meet the requirements of their customers. High-quality pellets can also command higher prices in the market, providing businesses with an additional source of revenue.

Furthermore, investing in a high-quality plastic pelletizing machine can help businesses reduce their overall production costs. By efficiently converting plastic waste into pellets, businesses can minimize the amount of waste generated during the recycling process. This can result in cost savings related to waste disposal and transportation. Additionally, high-quality pelletizing machines are designed to operate with minimal energy consumption, further reducing operational costs for businesses.

In addition to cost savings, investing in a high-quality plastic pelletizing machine can also help businesses meet environmental regulations and sustainability goals. By efficiently recycling plastic waste into high-quality pellets, businesses can reduce their environmental impact and contribute to a more sustainable future. This can also improve the reputation of businesses in the plastic recycling industry, leading to increased customer trust and loyalty.

Overall, investing in a high-quality plastic pelletizing machine offers numerous advantages for businesses in the plastic recycling industry. From increasing operational efficiency to reducing production costs and meeting environmental goals, these machines can help businesses achieve long-term success in the market. By making the investment in high-quality pelletizing machines, businesses can position themselves as industry leaders and contribute to a more sustainable future.

- Factors to Consider When Choosing a Plastic Pelletizing Machine

Plastic pelletizing machines have become an essential piece of equipment for the plastic recycling industry. These machines are used to convert plastic waste into plastic pellets, which can then be used to manufacture new products. With the increasing demand for recycled plastic materials, investing in a high-quality plastic pelletizing machine can be a cost-effective move for plastic recycling businesses. However, choosing the right plastic pelletizing machine is crucial, as there are several factors to consider before making a purchase.

One of the most important factors to consider when choosing a plastic pelletizing machine is the type of plastic materials that will be processed. Different plastic materials have different melting points and viscosities, so it is crucial to select a machine that can handle the specific type of plastic waste that will be processed. Some plastic pelletizing machines are designed to handle a wide range of plastic materials, while others are more specialized for specific types of plastics. It is essential to choose a machine that is suitable for the specific needs of your business.

Another factor to consider is the capacity of the plastic pelletizing machine. The capacity of the machine will determine how much plastic waste can be processed in a given amount of time. For businesses with high volumes of plastic waste, a machine with a larger capacity will be more efficient and cost-effective in the long run. It is important to assess the volume of plastic waste that will be processed and choose a machine that can handle the workload efficiently.

The quality of the plastic pellets produced by the machine is also an important consideration. High-quality plastic pellets are essential for manufacturing new products, as they will ensure the integrity and durability of the final products. It is important to choose a plastic pelletizing machine that can produce consistent and high-quality pellets. This may involve considering the design and technology of the machine, as well as the reputation of the manufacturer.

In addition to the machine itself, it is also important to consider the overall cost of ownership. This includes not only the initial purchase price of the machine but also the ongoing operating and maintenance costs. It is important to consider the energy efficiency of the machine, as well as the availability of spare parts and technical support. Choosing a reputable manufacturer with a proven track record of reliability and customer support can help to minimize the long-term costs of owning a plastic pelletizing machine.

Environmental considerations are also important when choosing a plastic pelletizing machine. Many plastic recycling businesses are focused on reducing their environmental impact, so it is important to choose a machine that is energy-efficient and produces minimal waste. Some machines may also be equipped with advanced filtration systems to minimize emissions and ensure compliance with environmental regulations.

In conclusion, investing in a high-quality plastic pelletizing machine can be a cost-effective move for plastic recycling businesses, but it is important to carefully consider all of the relevant factors before making a purchase. By choosing a machine that is suitable for the specific needs of the business, has a high capacity, produces high-quality pellets, and has manageable operating costs, businesses can maximize the return on their investment in plastic pelletizing technology.

- Cost-Effectiveness of High-Quality Plastic Pelletizing Machines

Plastic pelletizing machines have become an essential tool for businesses involved in the production of plastic products. These machines serve the crucial function of converting plastic waste and scrap into high-quality plastic pellets, which can then be used in various manufacturing processes. However, with the wide range of options available in the market, it is important to consider the cost-effectiveness of investing in a high-quality plastic pelletizing machine.

The cost of investing in a plastic pelletizing machine can vary greatly depending on the specific needs of a business. Factors such as the size of the machine, its production capacity, and the level of automation can all impact the overall cost. While it may be tempting to opt for a cheaper, lower-quality machine, it is important to consider the long-term implications of such a decision. High-quality machines may come with a higher initial investment, but they are often more efficient and reliable in the long run, resulting in significant cost savings over time.

One of the key advantages of investing in a high-quality plastic pelletizing machine is its ability to produce consistently high-quality pellets. This can have a significant impact on the overall production process, as the quality of the pellets directly affects the quality of the final plastic products. Machines that are able to produce uniform pellets with minimal waste can help businesses save money on raw materials and reduce the need for reprocessing or quality control measures.

Another important factor to consider is the operational efficiency of the machine. High-quality pelletizing machines are often designed to be more energy-efficient and require less maintenance, resulting in lower operating costs. Additionally, these machines may offer advanced features such as automated controls and integrated monitoring systems, which can further improve productivity and reduce the risk of downtime.

In addition to operational efficiency, the durability and longevity of a plastic pelletizing machine are important considerations. While cheaper machines may seem like a cost-effective option in the short term, they are more prone to breakdowns and may require frequent repairs or replacements. On the other hand, high-quality machines are built to withstand the rigors of continuous use, reducing the risk of costly downtime and the need for replacement parts.

Furthermore, the reputation and support of the manufacturer should also be taken into account when evaluating the cost-effectiveness of a plastic pelletizing machine. Investing in a machine from a reputable manufacturer with a track record of producing reliable and durable equipment can provide businesses with peace of mind and assurance that their investment will yield long-term benefits.

In conclusion, while the upfront cost of investing in a high-quality plastic pelletizing machine may be higher, the long-term cost-effectiveness of such a decision cannot be understated. From improved production efficiency and energy savings to reduced maintenance and downtime, high-quality machines offer a range of benefits that can result in significant cost savings for businesses in the plastic manufacturing industry. Investing in a high-quality machine ultimately proves to be the most cost-effective approach for businesses looking to enhance their plastic pellet production processes.

- Long-Term Benefits of Investing in a High-Quality Plastic Pelletizing Machine

Investing in a high-quality plastic pelletizing machine can yield long-term benefits for businesses in the plastics manufacturing industry. While the initial cost may seem significant, the returns on this investment can far outweigh the expenses over time. In this article, we will explore the numerous advantages of owning a high-quality plastic pelletizing machine, including increased production efficiency, improved product quality, reduced waste, and overall cost-effectiveness.

First and foremost, a high-quality plastic pelletizing machine can significantly enhance production efficiency. By converting raw plastic materials into uniform pellets, the machine allows for a more streamlined and automated manufacturing process. This results in higher output capacity and faster production cycles, ultimately leading to increased profits for the business. Additionally, the uniformity of the pellets ensures consistency in the final products, which is essential for meeting quality standards and customer expectations.

Furthermore, investing in a high-quality plastic pelletizing machine can help in reducing waste and minimizing production costs. The machine has the capability to process a wide range of plastic materials, including post-consumer or post-industrial waste, and convert them into reusable pellets. This not only reduces the amount of plastic waste that ends up in landfills but also lowers the need for purchasing raw materials, thus cutting down on production costs. As a result, businesses can improve their environmental footprint while also saving money in the long run.

In addition to the economic and environmental benefits, owning a high-quality plastic pelletizing machine can also contribute to the overall sustainability of the business. The reusable pellets produced by the machine can be used in various applications, such as injection molding, extrusion, and blow molding, making them a versatile and valuable resource. This versatility not only expands the potential markets for the business but also provides a sustainable solution for managing plastic waste.

Moreover, the long-term benefits of investing in a high-quality plastic pelletizing machine extend to the overall competitiveness of the business. By enhancing production efficiency, reducing waste, and improving product quality, businesses can position themselves as leaders in the industry. This can lead to increased customer satisfaction, a stronger market presence, and ultimately, a higher return on investment.

In conclusion, while the upfront cost of investing in a high-quality plastic pelletizing machine may seem daunting, the long-term benefits are undeniable. From increased production efficiency and improved product quality to reduced waste and overall cost-effectiveness, the advantages of owning such a machine are numerous. By making this investment, businesses can not only improve their bottom line but also contribute to a more sustainable and competitive future for the plastics manufacturing industry.

Conclusion

In conclusion, investing in a high-quality plastic pelletizing machine is indeed a cost-effective decision for businesses in the plastic recycling industry. Not only does it increase productivity and efficiency, but it also produces high-quality plastic pellets that can be sold at a premium. Additionally, the long-term cost savings and environmental benefits make it a worthwhile investment. With the right machine, businesses can significantly reduce their operational costs and minimize waste, ultimately leading to a more sustainable and profitable business model. Therefore, it is clear that the initial investment in a high-quality plastic pelletizing machine is well worth it in the long run.