Does A Plastic Pelletizing Machine Increase Output Consistency?

Are you curious about the impact a plastic pelletizing machine can have on output consistency? Whether you're a manufacturer or just interested in the plastic industry, this article delves into the potential effects a pelletizing machine can have on output quality. From increased efficiency to improved product consistency, we explore the potential benefits of investing in a plastic pelletizing machine. Dive into the details and discover how this technology could revolutionize your manufacturing process.

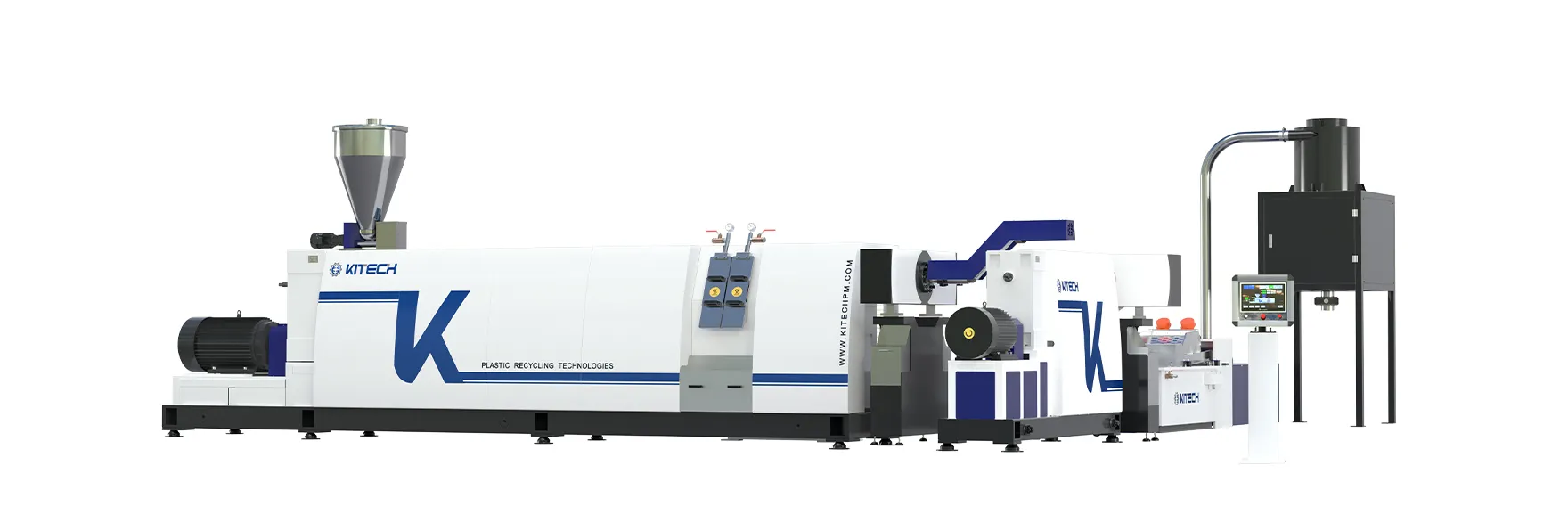

Introduction to Plastic Pelletizing Machines

Plastic pelletizing machines are an essential tool in the plastic manufacturing industry. They are used to convert raw plastic materials into small, uniform pellets that can be easily stored, transported, and used in the production of various plastic products. These machines come in a variety of sizes and configurations, and can be used for a wide range of plastic materials, including polyethylene, polypropylene, polystyrene, and more.

One of the key benefits of plastic pelletizing machines is their ability to increase output consistency. This means that the pellets produced by these machines are more uniform in size and shape, which can lead to a number of advantages for plastic manufacturers. In this article, we will explore the ways in which plastic pelletizing machines can increase output consistency and the impact this has on the plastic manufacturing process.

First and foremost, plastic pelletizing machines are able to increase output consistency by precisely controlling the size and shape of the pellets they produce. This is achieved through a combination of advanced technology and precise engineering, which allows the machines to consistently produce pellets with the exact specifications required by the manufacturer. This level of precision is difficult to achieve through manual methods, making plastic pelletizing machines an invaluable tool for ensuring consistent quality in the production of plastic products.

In addition to controlling the size and shape of the pellets, plastic pelletizing machines also allow for greater consistency in the density and composition of the pellets. This is important because variations in density and composition can affect the performance and properties of the plastic products being manufactured. By ensuring that the pellets are uniform in these respects, plastic pelletizing machines can help to maintain a high level of quality and consistency in the finished products.

Another way in which plastic pelletizing machines can increase output consistency is by minimizing waste and reducing the need for reprocessing. When pellets are not uniform in size, shape, density, or composition, they may be unusable for certain applications, leading to increased waste and the need for reprocessing. This can be a costly and time-consuming process for plastic manufacturers. However, by using a plastic pelletizing machine to produce consistently high-quality pellets, manufacturers can minimize waste and reduce the need for reprocessing, ultimately leading to greater efficiency and cost savings.

In conclusion, plastic pelletizing machines play a crucial role in increasing output consistency in the plastic manufacturing process. They are able to achieve this through precise control of the size, shape, density, and composition of the pellets they produce, ultimately leading to a higher level of quality and consistency in the finished products. By minimizing waste and reducing the need for reprocessing, these machines can also help to improve efficiency and lower costs for plastic manufacturers. As such, plastic pelletizing machines are an essential tool for any plastic manufacturing operation looking to maintain high levels of quality and consistency in their products.

Factors Affecting Output Consistency

Plastic pelletizing machines are an essential part of the plastic recycling process, but their effectiveness in maintaining output consistency hinges on several crucial factors. In this article, we will explore the various elements that impact the output consistency of plastic pelletizing machines and delve into whether these machines truly increase output consistency.

One of the primary factors affecting the output consistency of a plastic pelletizing machine is the quality of the raw material being fed into the machine. The size, shape, and moisture content of the plastic pellets can significantly influence the machine's ability to produce consistent output. Contaminants in the raw material, such as dirt or other non-plastic particles, can also disrupt the pelletizing process and result in inconsistent output. Therefore, ensuring that the raw material is of high quality and free from contaminants is essential for maintaining output consistency.

Another critical factor that impacts the output consistency of plastic pelletizing machines is the machine's design and operational efficiency. The design of the machine, including the size and shape of the die and the speed of the extruder, can determine the uniformity and quality of the plastic pellets produced. Additionally, regular maintenance and calibration of the machine are crucial for optimal performance and output consistency. Any malfunctions or deviations in the machine's operation can lead to variations in the pelletizing process, resulting in inconsistent output.

Furthermore, the processing parameters used during the pelletizing process, such as temperature, pressure, and residence time, play a significant role in determining the output consistency of plastic pelletizing machines. These parameters must be carefully controlled and monitored to ensure that the plastic pellets are being produced consistently. Variations in these processing parameters can lead to fluctuations in pellet quality and output consistency.

The type of plastic being pelletized also affects the output consistency of the machine. Different types of plastics have varying properties, such as melt flow index and viscosity, which can impact the pelletizing process. Therefore, it is essential to adjust the machine's settings and processing parameters based on the type of plastic being used to maintain consistent output.

In conclusion, plastic pelletizing machines have the potential to increase output consistency, but several critical factors must be considered and managed to achieve this goal. These factors include the quality of the raw material, the design and operational efficiency of the machine, and the processing parameters used during the pelletizing process. By addressing these factors and implementing proper maintenance and control measures, plastic pelletizing machines can indeed enhance output consistency, contributing to the efficiency and effectiveness of plastic recycling processes.

Benefits of Using a Plastic Pelletizing Machine

Plastic pelletizing machines have become an integral part of the plastic industry due to their numerous benefits. These machines are designed to convert plastic waste into uniform pellets, which are easier to handle and transport. In this article, we will explore the various benefits of using a plastic pelletizing machine and how it can help increase output consistency.

One of the main benefits of using a plastic pelletizing machine is the reduction of waste. By converting plastic waste into uniform pellets, the machine helps to minimize the amount of plastic that ends up in landfills. This not only helps to reduce environmental pollution but also contributes to a more sustainable approach to plastic recycling.

Another significant advantage of using a plastic pelletizing machine is the improvement in material handling. Plastic pellets are much easier to handle and transport compared to loose plastic waste. This makes it more convenient for plastic manufacturers to store and transport the material, ultimately leading to cost savings and increased efficiency.

Furthermore, the use of a plastic pelletizing machine can help to improve the quality and consistency of the final product. The machine ensures that the pellets produced are of uniform size and shape, which is essential for producing high-quality plastic products. This level of consistency also helps to reduce the risk of defects and inconsistencies in the final product, ultimately leading to higher customer satisfaction and reduced production costs.

In addition to these benefits, using a plastic pelletizing machine can also help to increase production output. By converting plastic waste into pellets, the machine allows for a more efficient and streamlined production process. This not only helps to increase production capacity but also improves overall productivity and reduces downtime.

Another advantage of using a plastic pelletizing machine is the versatility it offers in terms of the types of plastic materials that can be processed. These machines are designed to handle a wide range of plastic materials, including polyethylene, polypropylene, and polystyrene, among others. This flexibility allows for greater adaptability in the recycling and reprocessing of various types of plastic waste.

Furthermore, the use of a plastic pelletizing machine can also help to improve the overall sustainability of plastic manufacturing processes. By converting plastic waste into reusable pellets, the machine supports the concept of a circular economy and promotes a more sustainable approach to plastic recycling.

In conclusion, the benefits of using a plastic pelletizing machine are numerous and varied. From reducing waste and improving material handling to increasing production output and promoting sustainability, these machines play a crucial role in the plastic industry. By investing in a plastic pelletizing machine, manufacturers can not only improve the quality and consistency of their products but also contribute to a more sustainable and efficient approach to plastic recycling.

Case Studies on Improved Output Consistency

Plastic pelletizing machines play a crucial role in the plastic recycling industry, as they are responsible for turning plastic waste into reusable plastic pellets. One of the key factors that manufacturers and operators look for in a pelletizing machine is output consistency. In this article, we will explore the impact of plastic pelletizing machines on output consistency through case studies and examples.

Case Study 1: Company A

Company A, a recycling plant specializing in plastic waste, faced issues with inconsistent output from their existing pelletizing machine. This inconsistency led to quality issues with the plastic pellets, resulting in customer complaints and increased production costs. In an effort to address this issue, the company invested in a new plastic pelletizing machine with advanced features designed to improve output consistency.

After the installation of the new machine, Company A observed a significant improvement in output consistency. The machine's precise temperature control, efficient cooling system, and adjustable cutting speed allowed for more uniform and consistent plastic pellets to be produced. As a result, the company saw a reduction in customer complaints and a decrease in production costs due to less waste and rework.

Case Study 2: Research Facility B

Research Facility B, a leading institution in polymer research, conducted a study to evaluate the impact of different plastic pelletizing machines on output consistency. The research facility utilized various machines from different manufacturers and tested their performance using standardized testing methods. The results revealed that the design and technology of the plastic pelletizing machine had a direct impact on output consistency.

The machines with advanced features such as twin-screw extruders, precise die designs, and automated control systems demonstrated superior output consistency compared to traditional single-screw extruders. The study emphasized the importance of investing in modern plastic pelletizing machines with improved technologies to achieve better output consistency and overall production efficiency.

Case Study 3: Manufacturer C

Manufacturer C, a supplier of plastic pellets to various industries, recognized the need to maintain high output consistency to meet the stringent quality requirements of their customers. The company replaced their outdated pelletizing machine with a state-of-the-art model that boasted enhanced process control and monitoring capabilities.

The new machine enabled Manufacturer C to achieve unparalleled output consistency, reducing the variability in pellet size, shape, and density. This not only improved the overall quality of their plastic pellets but also enhanced their reputation as a reliable supplier in the market. The investment in a new plastic pelletizing machine ultimately led to increased customer satisfaction and higher demand for their products.

In conclusion, the case studies presented in this article highlight the notable impact of plastic pelletizing machines on output consistency. The advancements in technology and design of modern pelletizing machines have proven to significantly improve the uniformity and quality of plastic pellets, leading to a range of benefits for recycling plants, research facilities, and manufacturers. As the demand for high-quality recycled plastic continues to rise, investing in a plastic pelletizing machine with improved output consistency is crucial for sustainable and efficient plastic recycling processes.

Considerations for Choosing the Right Pelletizing Machine

When it comes to plastic pelletizing machines, choosing the right one for your specific needs is crucial. There are several considerations to keep in mind when making this decision, all of which can impact the output consistency of the machine. In this article, we will discuss the key factors to consider when selecting a plastic pelletizing machine, and how it can affect the overall output consistency.

One of the first considerations when choosing a plastic pelletizing machine is the type of plastic material that will be processed. Different types of plastics have different properties, and not all pelletizing machines are suitable for all types of plastics. Some machines may be better suited for processing rigid plastics, while others may be designed for more flexible materials. It is important to ensure that the machine you choose is capable of handling the specific type of plastic material you will be working with, in order to achieve consistent output.

Another important factor to consider is the capacity of the pelletizing machine. The capacity of a machine refers to the amount of plastic material it can process within a given amount of time. It is important to choose a machine with a capacity that aligns with your production needs. If a machine is constantly operating at or near its maximum capacity, it can lead to inconsistent output and potential breakdowns. On the other hand, a machine that is too large for your needs can result in inefficient use of resources. Therefore, it is important to carefully consider the capacity of the pelletizing machine in relation to your production requirements.

The design and features of the pelletizing machine also play a significant role in determining the output consistency. Look for a machine that offers features such as adjustable cutter speed, temperature control, and precise pellet length adjustments. These features can help ensure consistent pellet quality and size, which is crucial for downstream processes such as extrusion or injection molding. Additionally, the overall design of the machine, including the feeding mechanism, die head, and cooling system, can also impact the output consistency. It is important to carefully evaluate the design and features of a pelletizing machine to ensure it meets your specific requirements.

Furthermore, it is essential to consider the maintenance and support services offered by the manufacturer of the pelletizing machine. Regular maintenance is crucial for ensuring the consistent performance of the machine. Look for a manufacturer that provides comprehensive support services, including spare parts availability, technical assistance, and training for machine operators. A reliable manufacturer will also offer a warranty and service agreement to provide peace of mind and minimize downtime due to maintenance issues.

In conclusion, choosing the right plastic pelletizing machine is essential for achieving consistent output. Considerations such as material type, capacity, design features, and manufacturer support services all play a crucial role in determining the output consistency of the machine. By carefully evaluating these factors and selecting a machine that aligns with your specific production requirements, you can ensure a reliable and efficient pelletizing process.

Conclusion

In conclusion, a plastic pelletizing machine has proven to significantly increase output consistency in the plastic manufacturing industry. By efficiently processing plastic materials into uniform pellets, this machine ensures a more reliable and predictable production process. This not only improves the quality of the end product but also reduces waste and enhances operational efficiency. Overall, investing in a plastic pelletizing machine is a worthwhile decision for any manufacturer looking to optimize their production output and consistency. With the potential for long-term cost savings and improved product quality, it’s clear that this machine is a valuable asset for any plastic manufacturing operation.